From Concept to Initial Prototypes of the NFC Access Bracelet — In 90 Days

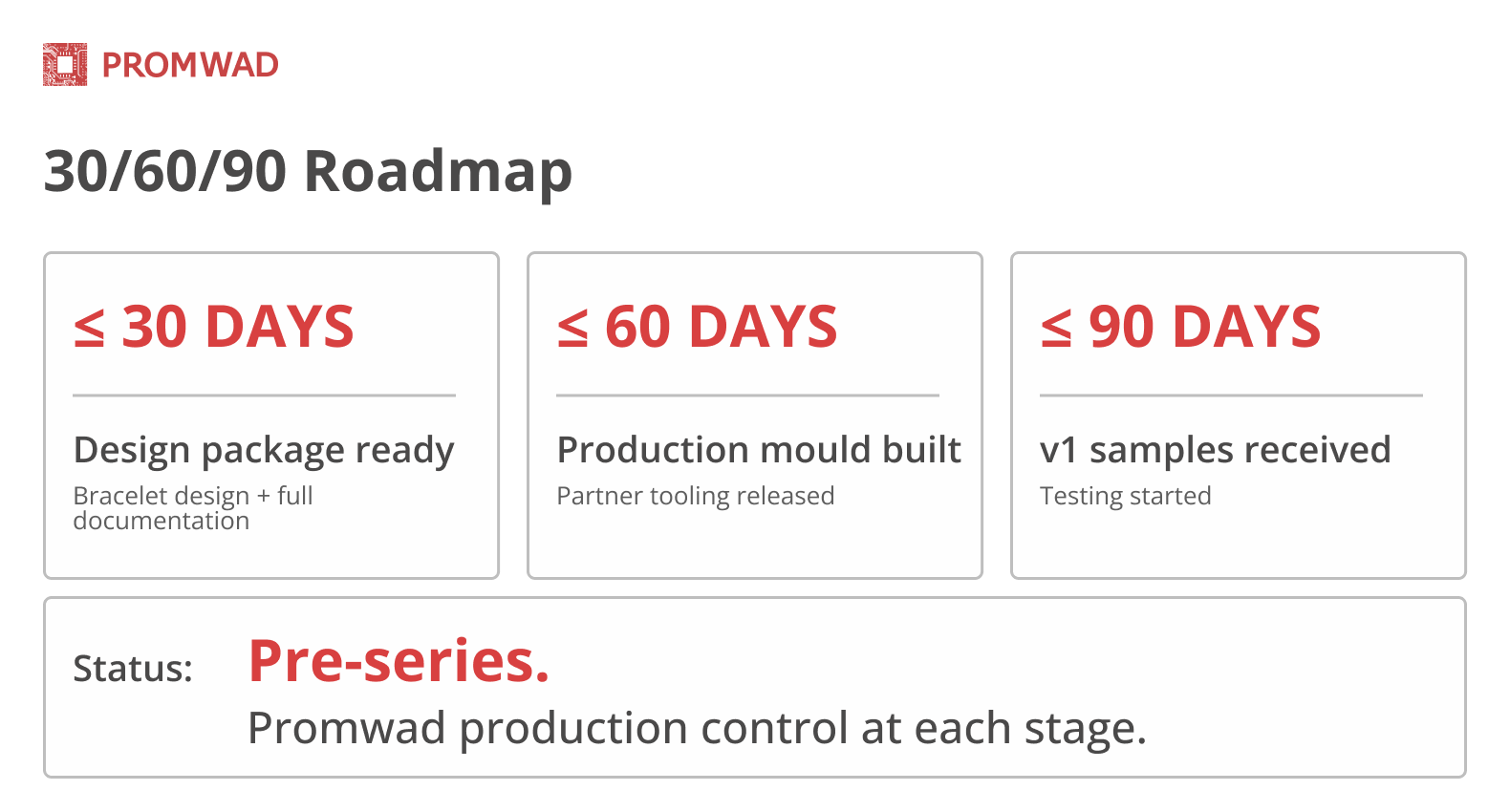

Project in a Nutshell: We engineered the industrial design, developed the electronics with a flexible antenna on an NXP platform, and prepared a molded silicone case bracelet for a wearable pass at the request of a U.S digital identification solutions provider. This is a disposable bracelet: if someone tries to remove the bracelet, it automatically stops working. We received the first samples in 90 days and began testing; the second iteration (200 units) addressed the initial comments. In the summer of 2025, our team presented a consolidated solution. The project is currently in pre-production.

Client & Challenge

Our client is a major provider of digital identification solutions based in the U.S. The company approached us to create a wearable, non-transferable NFC wristband for access control that automatically stops working when someone tries to remove it. Three factors were important to the client: speed of execution, a transparent work plan, and a single point of responsibility for the entire journey from design to pre-production.

After an unsuccessful attempt with another supplier, the client needed a predictable path to pre-production in 2025: we delivered this through reliable ID/ME design, disciplined short iterations, and single responsibility from design to prototyping.

Solution

The Promwad team handled the entire device development cycle and production preparation. First, we developed the bracelet's industrial design — its shape, ergonomics, and manufacturability — to ensure comfort and stable production. Then we developed a flexible printed circuit board with an antenna and electrical connection for the NXP NTAG 424 DNA microchip, and then designed a molded silicone case, coordinating the geometry and tolerances for assembly and sealing.

The manufacturing part included mold making by a partner, trial batch production, and logistics. Quality control was built into every stage: from incoming material inspection and geometry verification to sample acceptance against checklists.

Software was deliberately not included in this phase: the goal was to validate the mechanics, components, and assembly, and get the product ready for pre-production.

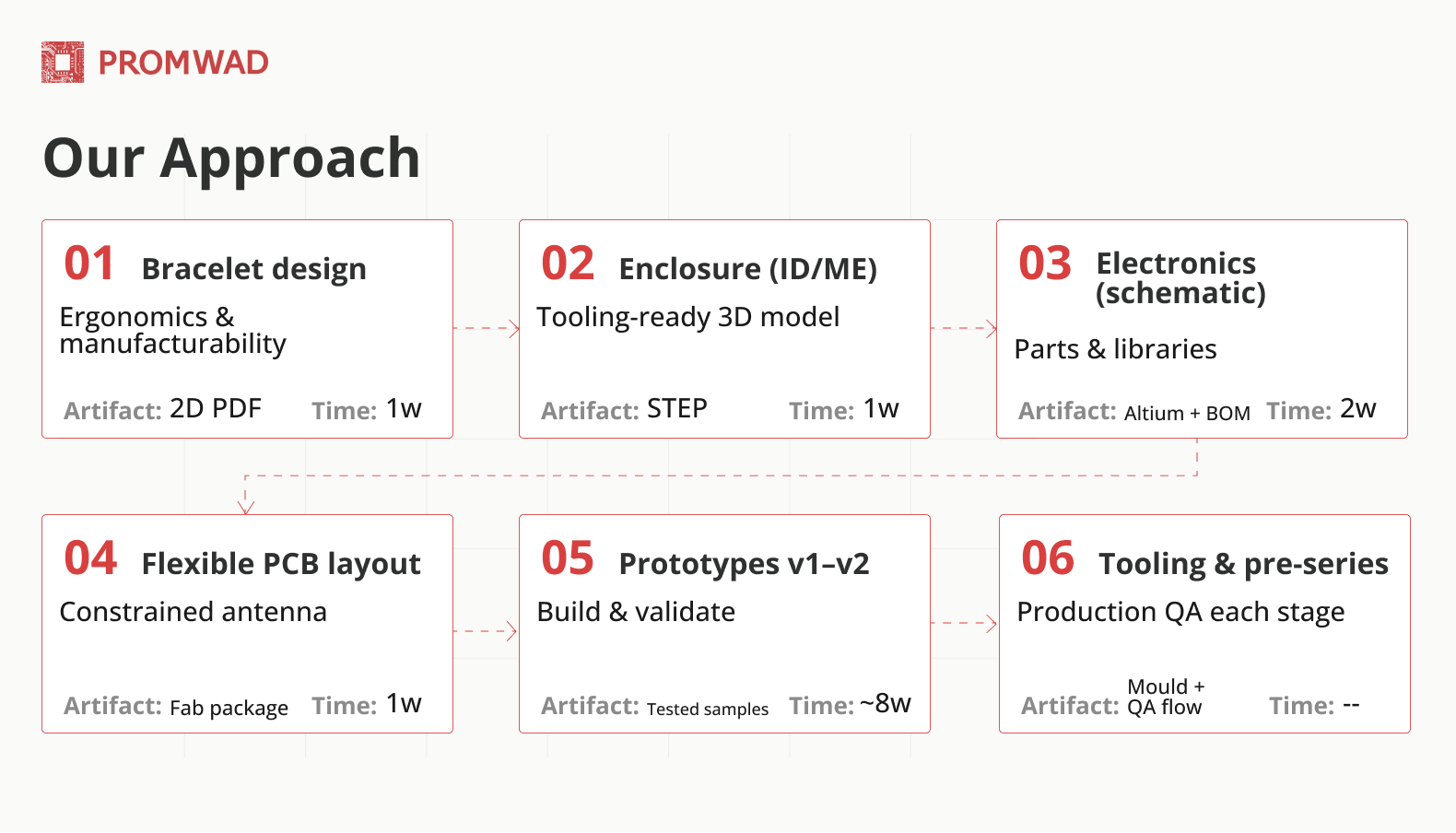

We worked iteratively in short cycles. At each stage, we created a specific artifact — 2D concepts, then a STEP model, then a design in Altium with a BOM and a fab package. At the end of each iteration, we held a demonstration, refined the solutions, and moved on to the next stage. Planning was done weekly/biweekly with weekly status updates in a unified format; changes and risks were tracked using a shared change log.

The project manager was responsible for coordination: he linked design, mechanics, electronics, molding, and manufacturing, and also monitored deadlines and communications. The team included an industrial designer, a mechanical engineer, a chematic engineer and a PCB designer.

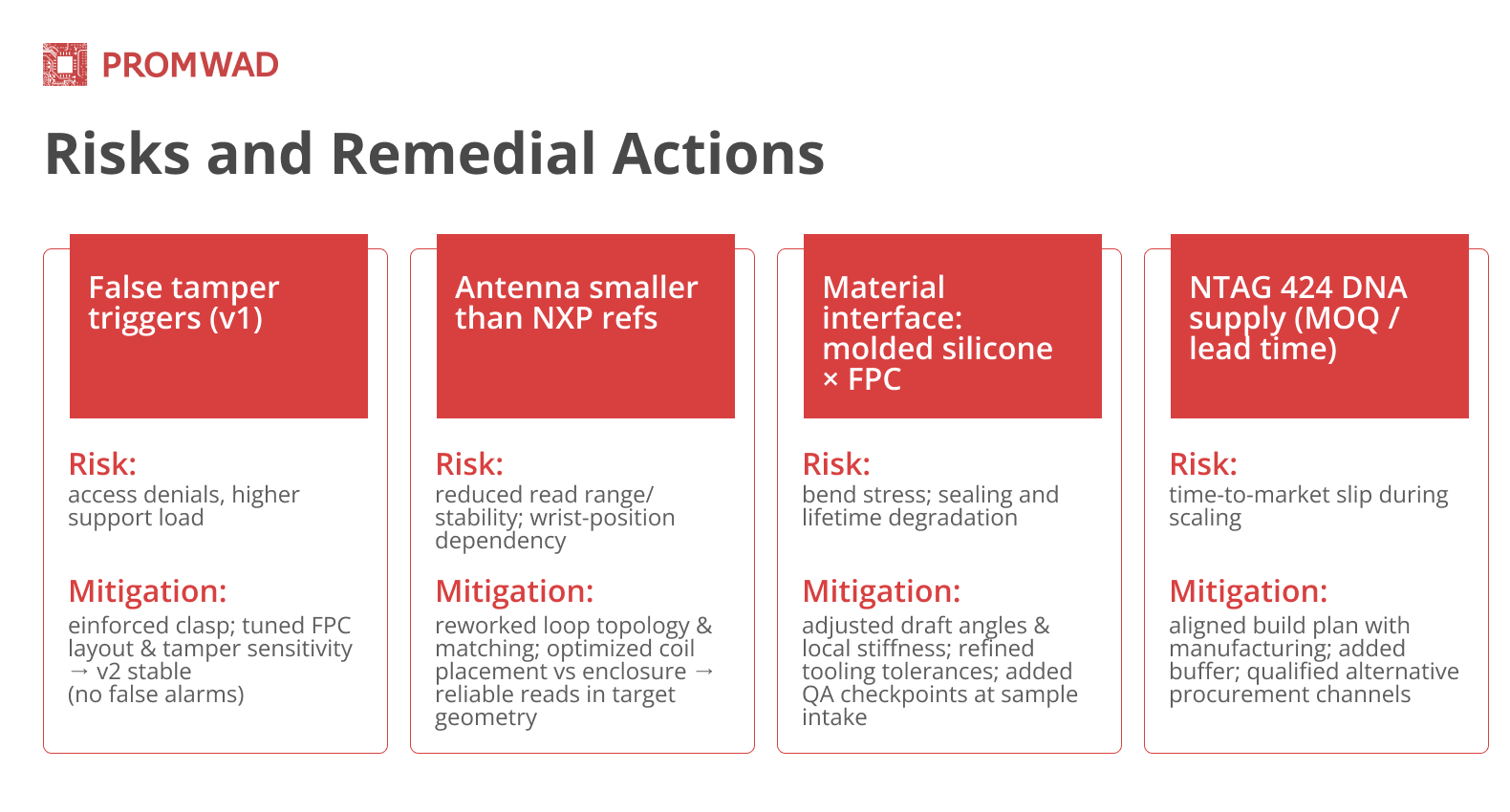

Risks and Remedial Actions

During the initial iterations and tests, we identified key risks affecting access reliability, device durability, and pre-production launch timelines. Below is information about what this meant for the business and the decisions we made.

Business Value

The client now has a consolidated solution that has undergone two iterations (v1 and v2, 200 units). The mold has been manufactured, quality control has been established, and a complete set of design documentation has been prepared for subsequent batches. This ensures pre-production readiness in 2025 and allows for scaled production with synchronized procurement of key components (NXP NTAG 424 DNA). Our client has added a new product to its portfolio: a wearable, non-transferable pass for secure infrastructure.

Ready to start production on a tight timeline with full process transparency? Get in touch.

Reach Out

More of What We Do for Manufacturing

- Electronics Manufacturing Services: Explore our turnkey electronics contract manufacturing services.

- Smart Wireless Thermostats: a case study of turnkey development of a device that would pay for in two years.

- Promwad Boosts Businesses with Wearable Devices: learn how we help our clients in various industries improve efficiency with wearables, mobile apps, and data analysis.