3D-printing vs machining: the best way for prototyping

One of the important stages in the development of electronics is prototyping. As a rule, customers have to choose between machining and 3D-printing. Previously it was much easier to make a decision because materials for 3D-printing were expensive and not reliable enough. Now problems with materials are solved and you need to think carefully before choosing the technology for creating a sample. We will try to help you in making this choice.

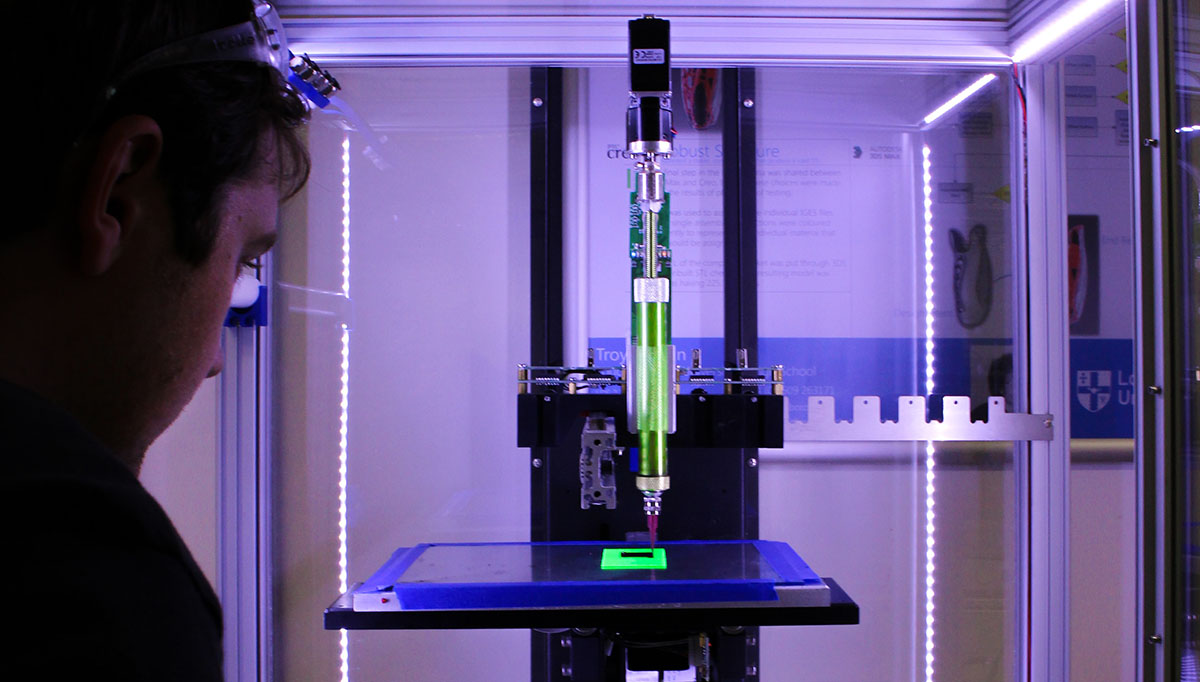

Use 3D printing for:

Difficult elements. In the case of standard processing of parts, it will be very costly to create thin and sharp parts of the body. For a 3D-printer, this is not a problem - on the contrary, you will pay less for less material.

Visualization. The 3D-model will allow you to visually demonstrate the future device to potential customers as accurately as possible and with lower costs that will be required for traditional development.

Ergonomic evaluation. 3D-printing allows evaluating a part in terms of ergonomics. So, you can test several configurations of the enclosure at a less money and time. For example: with machining, curved parts will require a lot of effort, while for printing there is no time difference for a curved and straight surface.

When is it better to use machine printing?

Accuracy. Accuracy is the most important argument for machining. The best option a 3D-printer can offer is the accuracy of 0.05 mm (0.002 inches), which is often not enough. Workshops, in turn, can offer twice as better result.

Materials. As mentioned earlier, the materials for 3D-printing are not as fragile as they used to be, but they are still clearly inferior to other materials. For example, you can select a lot of materials using the traditional device creation technique.

Large value. Despite the fact that 3D-printing will cope better with complex details, the costs of materials and 3D-printers will significantly exceed the costs of machine processing with a large production volume.

It is important to understand that you do not need to exclude one of the options. On the contrary, you can combine them to create the perfect enclosure at minimum cost. In any case, we are always happy to help you determine the technology and support the process of creating a prototype. Just contact us.