How Automotive Ethernet Minimises Number of Wires and Streamlines Connectivity

By Alexey Safonov

Head of the Automotive Unit at Promwad

Wires are one of the most costly and extensive components in a modern vehicle, with a total length of up to 4 km. And the number of automotive electronic systems continues to grow — along with the requirements for the speed and reliability of data transmission. Traditional communication buses can no longer cope with it, but there is a solution — automotive Ethernet networks — which we are implementing in our clients’ projects.

As more vehicles are equipped with new electronic systems to communicate with their environment within the vehicle-to-everything (V2X) concept, there is a growing need for reliable, flexible and seamless communication to transfer increasing amounts of data for mission-critical applications:

- ADAS and IVI systems;

- radars and lidars;

- digital mirrors and cameras.

By 2030, the amount of data to be processed from automotive applications will equal the amount in today's user networks. However, traditional communication buses such as CAN, CAN-FD and LIN will not be able to meet these growing demands for fast and reliable data transmission. This is where the automotive Ethernet standard comes in, supporting high speeds from 100 Mbit/s to 2 Gbit/s.

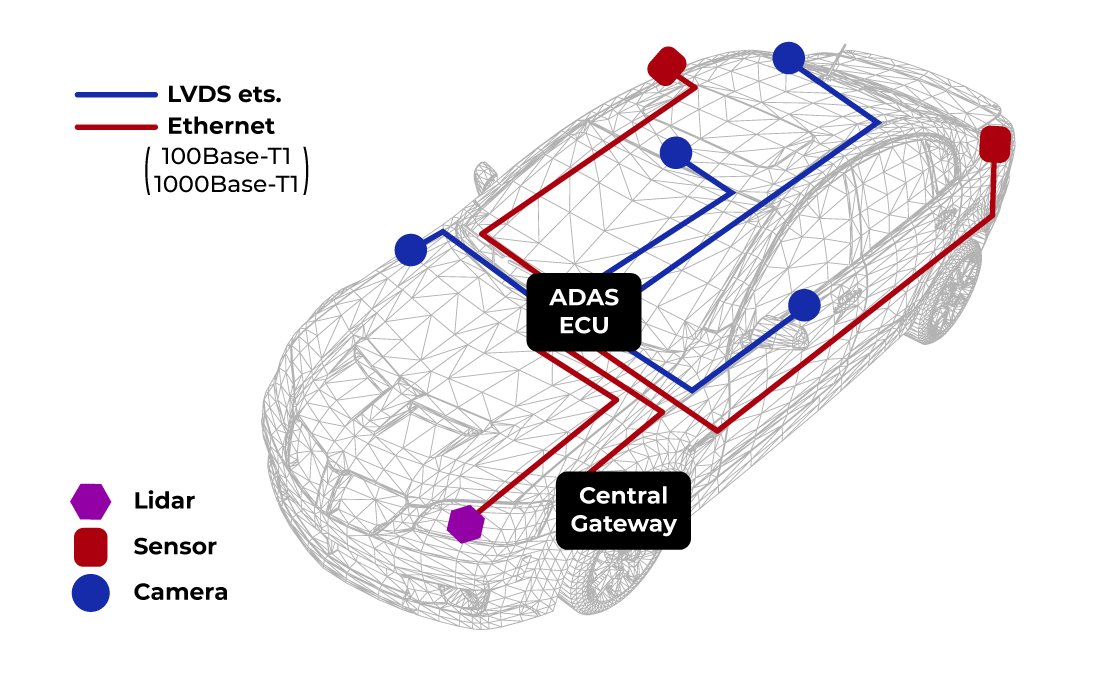

Automotive Ethernet and connectivity for lidars, sensors, and cameras in vehicles

Vehicles produced by world giants like BMW, Jaguar, and Volkswagen have already been using automotive Ethernet for several years. Now, more than 160 companies have joined the OPEN Alliance, a non-profit group of tech providers encouraging the adoption of Ethernet in automotive applications: GM, Hyundai, Reno, Volvo, and also such chip vendors as NXP, Renesas and others.

Here are the advantages of Ethernet in cars that make this standard attractive for automotive applications:

- High bandwidth and data rates, which are important for ADAS, VI, and autonomous driving functions.

- Reduced wiring complexity by minimising the number of wires required for Ethernet.

- Scalability and flexibility to integrate new capabilities without completely overhauling the current infrastructure.

- Stable and predictable connectivity to run mission-critical applications.

In addition, according to experts from the American semiconductor company Broadcom, the use of Ethernet cables can significantly reduce the weight of cars.

The automotive Ethernet solutions can be realised with time-sensitive networking (TSN) protocols. They ensure precise time synchronisation and guaranteed data delivery without delays. TSN works with other IEEE standards and provides fast system start-up, reliability and security.

Ethernet in the automotive industry does not require eliminating traditional communication buses such as CAN, CAN-FD and LIN. Although they are not able to provide a sufficient level of efficiency, they still play an important role in automotive applications. For example, it is more cost-effective to use them in applications without strict requirements for data transmission speeds.

"Ethernet in automotive projects is the way to the future. By utilising its speed and reliability, we provide seamless connectivity and unlock the potential of smart vehicles. And it's not just about connectivity, it's about rethinking the way vehicles connect, share data and create new driving experiences."

— Alexey Safonov, Head of the Automotive Unit at Promwad

Promwad Case Studies with Automotive Ethernet

Here are some case studies of how automotive Ethernet technology can be applied to the design of electronics and software for new vehicles:

Case Study #1. New Version of the 2-Din Multimedia System for Various Car Models

Commissioned by a German OEM, we designed software and hardware for an infotainment system with data transfer via automotive Ethernet.

The Promwad engineers were responsible for collecting system requirements, software architecture, automotive Ethernet testing and integration of the IVI system with the following features:

- multilingual voice activation;

- rear view camera apps;

- HVAC HMI;

- GPS with and route guidance;

- management of air conditioning systems;

- audio playback from USB drives / iPods.

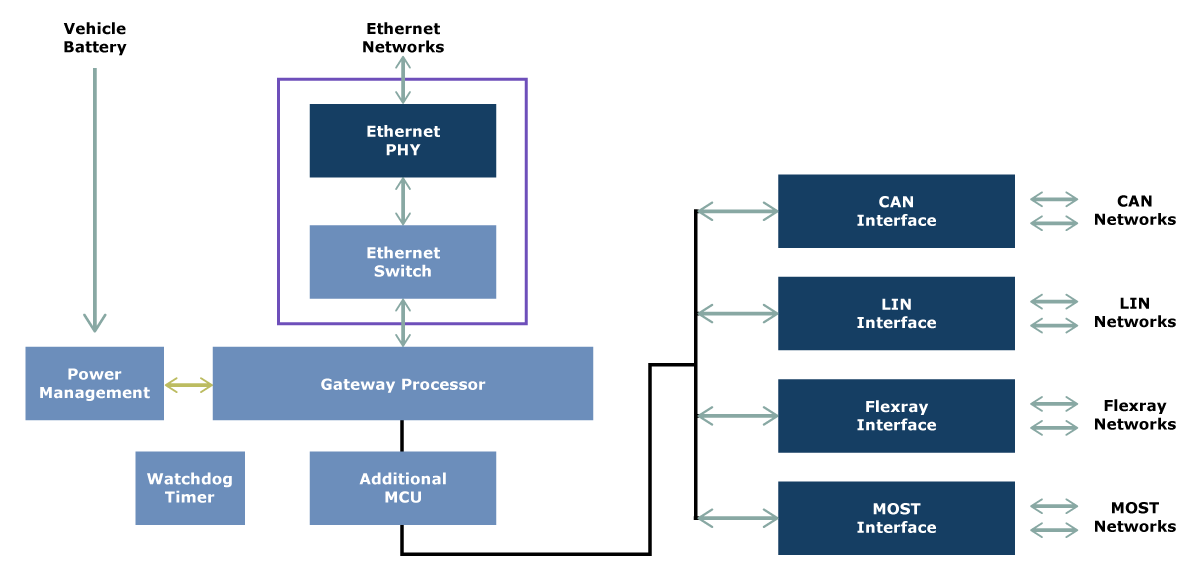

Case Study #2. Gateway for Telemetry System

Now, the Promwad team is designing a gateway for reliable data transfer between the control unit and the vehicle telemetry system — with automotive ethernet security in mind.

Schematic illustration of the automotive gateway operation principle

The new gateway has a standard set of functions:

- network integration;

- data aggregation;

- communication management;

- cybersecurity;

- over-the-air updates;

- diagnostic capabilities;

- integration with advanced technologies.

Case Study #3. Automotive 360 Vision System

Commissioned by a supplier of all-round vision solutions for vehicles, we upgraded an outdated 360-degree camera system, including reworking its software and replacing discontinued components with FPGA Crosslink-NX by Lattice and the NXPk118 microcontroller by NXP.

How a 360 camera works. Image by Promwad

The new around-view system supports MIPI CSI, CAN and USB interfaces. Automotive Ethernet as a communication standard ensures instantaneous data transmission after processing. Target system for image transferring could be additional display, IVI system or subsystem for AI recognition.

***

As the industry moves towards electrification, V2X connectivity and autonomous driving, automotive Ethernet plays a crucial role in shaping the future of vehicles. Its high bandwidth, scalability and reliability make it a key enabler for next-generation automotive systems.

Contact us to find out how your engineering solution can benefit from automotive Ethernet networks: