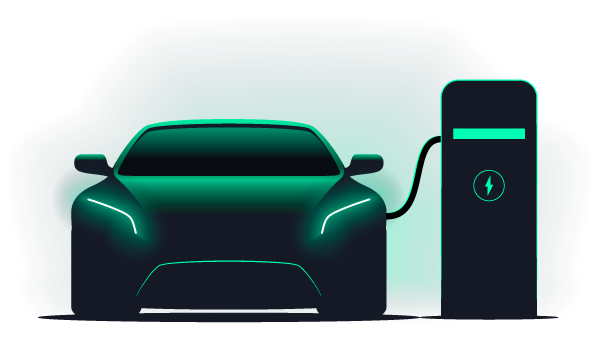

Vehicle Electrification

Custom Vehicle Electrification Solutions

We develop vehicle electrification solutions, converting internal combustion engines into electric motors. Our team selects and integrates system components, tailoring them for trucks, cars, boats, and heavy machinery.

Our engineers can work alongside your team of mechanics and electricians. We’re ready to assist you in reverse engineering and software development, ensuring each component functions seamlessly within your system.

Why Our Clients Order Electrification Solutions

Specialised Vehicles We Work With

Compactor trucks

with waste press

Emergency medical

service vehicles

Side and rear

loader waste trucks

Refrigerated

delivery trucks

Utility

vehicles

Municipal

vehicles

Construction

vehicles

Agricultural

vehicles

Street

sweepers

Our Automotive Electrification Services

Our automotive electrification services span from truck to ship electrification solutions.

The complete conversion process for a single model typically takes 8-12 months.

And with comprehensive tech documentation from our clients, the process will speed up even more as we'll skip the reengineering phase. We'll get the result faster for additional vehicles of the same model.

Reverse engineering

Reverse engineering includes examining and disaggregating systems to understand their operation. This process helps us create detailed requirements for the following steps.

Integration

Using insights gathered through reverse engineering, we take existing components, connect them, and combine them into the system.

Сode creation

After integration, we build missing components, which could involve emulation, simulation, new code, algorithms, interfaces, and more.

QA and code testing

Employing various tools, including CAN, Ethernet, and JTAG, we validate that old and new components interact seamlessly and do not overload the system.

Our Case Study on Vehicle Electrification

We transformed diesel utility trucks into electric vehicles for a German automotive company. They now offer integrated features such as heating, air conditioning, recuperation, hill start assist, and AC/DC charging. This electrification broadened our client's market reach within the DACH region and EU cities.

Our team integrated an ECU based on a microcontroller by TTControl to manage the electrical system — motor, inverter, charging, and more. Using Codesys, we developed ST language code for the device, enhancing adaptability.

More about this case study →

Our Tech Stack

HYDAC eVision² 7.0, Qt

6 slaves, 126 battery cells, 380V

C,C++,Rust, ST (structured text), similar to PLC programming

Codesys, Vector

Charging up to 20/100 kW

HYDAC TTC-580 EV system and vehicle interface

ARADEX-powered electric motor and inverter technology. Key specifications: power output of 90 kW for the electric motor and a maximum torque of 1150 Nm.

KEB's inverter for power steering | MOTEG motors for the air brake system compressor | Recuperation | Cruise control | Air conditioning

Whom We Serve

We collaborate with specialised vehicle suppliers who opt for automotive electrification. Our team integrates electric motors, batteries, inverters, and other components to transform diesel vehicles into electric units. Such projects often involve the reverse engineering of communication protocols, ensuring that all systems operate flawlessly despite component replacements or removals.

EV manufacturers

We help our clients in the EV manufacturing sector select suitable components, outline requirements and create comprehensive software to ensure seamless operation between their chosen components. Typically, they have thorough documentation on how original electronic systems function, but even when it is unavailable, our engineers employ experimental methods to decipher how vehicle components operate.

Why Promwad

Automotive experience

Our background in highly regulated automotive projects allows us to work in the most complex project environments in the industry.

Flexible resources

We offer flexibility for our on-site resources, essential for hands-on tasks such as system bring-up, tuning, and thorough testing of hardware and software solutions.

In-depth ECU expertise

Our understanding of ECU specifics allows us to create various modules and systems across electric, hybrid, and internal combustion vehicles.

Our Engagement Models

Time & Material

– Payments for actual hours worked

– Regular reporting of time and results

– Regular communication with the team

– Connecting / disconnecting engineers on request

– Flexible development process

Dedicated Team

– Fixed monthly costs

– Custom-built team with specific competencies

– Fully dedicated engineering team

– Comprehensive IT infrastructure

– Max efficiency for complex projects

Project-Based

– Budget control

– Reduced risk

– Flexible resource allocation

– Clear scope

– Predictable timeline

– Quality control

Do You Need a Quote for Vehicle Electrification Solution?

Drop us a line about your project! We will contact you today or the next business day. All submitted information will be kept confidential.

FAQ

Can vehicle electrification companies assist with charging infrastructure setup for electric vehicles?

As a vehicle electrification company, we can provide comprehensive assistance in setting up charging infrastructure. We'll analyse your requirements, recommend suitable charging solutions, and oversee installation.

This includes selecting appropriate charging stations, determining their placement for optimal accessibility, and coordinating with electrical contractors for safe and efficient installation. Our team ensures that charging stations are compatible with electric vehicle models and support various charging standards, such as Level 1, Level 2, and DC fast charging.

Do you offer consulting services for vehicle electrification projects?

Yes, we provide consulting services tailored to vehicle electrification projects. Our team assesses your unique industry-specific needs, offering insights into component selection, system design, software integration, and regulatory compliance. We also focus on cost-benefit analyses and project planning.

With our deep understanding of conventional and electric vehicle systems, electrification as a service at Promwad includes defining project scope, objectives, and milestones. This involves assessing battery technologies, motor options, charging solutions, and sustainability considerations.

What is the significance of reverse engineering in automotive electrification?

Reverse engineering is critical in automotive electrification for enabling a seamless transition from combustion engines to electric motors. It involves deconstructing existing vehicles, comprehensively analysing their components, and understanding their interactions. This process helps identify opportunities for integrating electric powertrains, batteries, and control systems.

It also facilitates the development of custom solutions, minimising operational disruptions and errors. By reverse engineering of communication protocols, wiring diagrams, and control logic, vehicle electrification companies ensure that the converted vehicle operates reliably and efficiently, meeting performance standards.