Enclosure Materials and Case Design in 2025

The housing of an electronic device is more than a cover — it is a functional, aesthetic, and regulatory component of the final product. The choice of enclosure materials directly affects durability, usability, and manufacturing costs. Whether it is a custom plastic case for electronics or a sheet metal case design for industrial equipment, enclosure development requires balancing engineering, aesthetics, and compliance with modern standards.

In this article, we will explore the most common materials used in enclosure engineering today, from plastics and composites to metals and glass. We will also look at plastic electrical enclosures, polycarbonate electrical enclosures, and the role of color management through Pantone and RAL systems in enclosure design.

The importance of enclosure materials

Enclosure materials determine the physical properties of a device: weight, strength, thermal resistance, and environmental protection. For instance, polycarbonate electrical enclosures offer high impact resistance and transparency, making them suitable for demanding applications. In contrast, sheet metal case design prioritizes rigidity, shielding, and durability, often used in telecom, industrial, or automotive equipment.

Plastic enclosures for electronics dominate consumer products because they are lightweight, affordable, and easy to manufacture. Metal electrical enclosures, on the other hand, are essential for critical systems that require electromagnetic compatibility and robust performance in harsh environments.

The selection process involves more than just technical performance. A plastic enclosure box for electronics may also need to meet ergonomic and aesthetic expectations. Here, color consistency plays an important role, often managed through Pantone color selection or RAL and Pantone matching. This ensures the product aligns with branding requirements and visual standards.

Plastic and metal enclosures: options and applications

Plastic electrical enclosures

Plastics such as ABS, polycarbonate, and PVC are widely used for small and medium-sized devices. Plastic enclosures for electronics offer flexibility in form factors, allowing engineers to design sleek, compact housings.

Polycarbonate electrical enclosures are known for impact resistance and temperature tolerance. They are common in outdoor IoT devices, lighting systems, and industrial control units.

Custom plastic case for electronics enables tailored solutions that fit specific PCB layouts, connectors, and user interfaces. These cases can be optimized for mass production through injection molding.

Plastic enclosure boxes for electronics are often employed in low- and mid-cost consumer products, where lightweight and affordability are key.

Metal electrical enclosures

For high-end or industrial applications, metals such as aluminum and stainless steel are used. Metal housings provide strength, heat dissipation, and shielding from electromagnetic interference.

Sheet metal case design allows scalable production using stamping, bending, and welding technologies. This approach is common in telecom equipment, data centers, and power distribution systems.

Metal electrical enclosures are also preferred in automotive electronics, where vibration resistance and heat management are critical.

Color and surface design: Pantone and RAL standards

Aesthetic factors are as important as engineering in modern enclosure design. Customers increasingly expect electronic devices to reflect brand identity through consistent colors and finishes.

Pantone color selection provides precise control of brand colors across different production batches.

RAL and Pantone systems are both used in enclosure engineering, with RAL being more common in Europe for industrial equipment, and Pantone often used in consumer and design-driven markets.

These standards ensure that whether a company is producing plastic electrical enclosures or sheet metal housings, the final product aligns visually with marketing requirements. Surface treatments such as anodizing, powder coating, or textured plastics enhance both durability and visual appeal.

Prototyping and combinations of materials

Not all materials suitable for production are available for prototyping. For example, when testing a plastic enclosure box for electronics, engineers may use 3D printing materials that mimic ABS or polycarbonate behavior. This allows early testing of assembly, ergonomics, and thermal management.

Hybrid solutions are also common. A device may combine plastics with rubber seals for waterproofing, or a polycarbonate electrical enclosure with metal reinforcements for added strength.

The ability to combine enclosure materials effectively is a key factor in modern enclosure engineering. It ensures that final products meet safety, durability, and cost targets.

Case studies of enclosure engineering

Marine electronics: Plastic and glass combinations were used in fish finder housings. Rubber inserts provided waterproofing, while transparent glass improved usability.

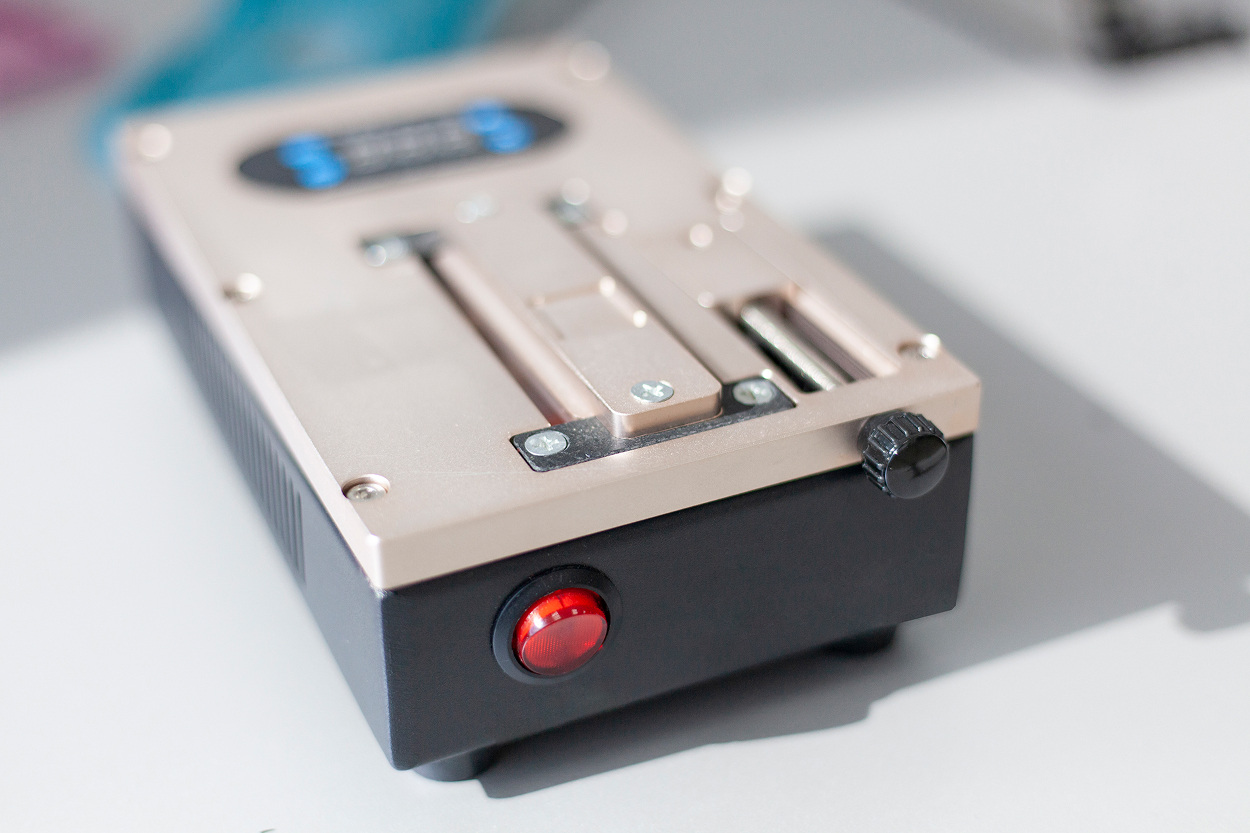

Consumer audio equipment: A custom plastic case for electronics combined with anodized aluminum and quartz glass created a stylish and functional enclosure. This hybrid approach balanced thermal management and aesthetics.

Industrial control systems: Sheet metal case design ensured compliance with electromagnetic shielding standards, while powder-coated finishes matched corporate colors using RAL references.

These examples show how enclosure materials influence both the functionality and identity of electronic products.

Consulting and compliance in enclosure development

Engineering analysis is critical in enclosure projects. Simulations of thermal management, stress distribution, and molding flow help validate designs before production.

Consulting services also ensure compliance with safety and durability standards. Plastic electrical enclosures and metal housings alike must align with IEC 60529 for ingress protection, UL 94 for flammability of plastics, and ISO standards for automotive or industrial use.

“When selecting enclosure materials, we evaluate technical performance, compliance with international standards, and manufacturing feasibility. This approach ensures durable products that meet both engineering and branding requirements,” — says Ivan Kuten, Co-owner and Tech Expert at Promwad.

By combining advanced engineering with compliance and design considerations, companies achieve enclosures that are functional, durable, and visually consistent.

Future outlook: enclosure materials in 2025

The landscape of enclosure materials continues to evolve. In 2025, the demand for recyclable plastics, sustainable composites, and miniaturized sheet metal solutions is growing. Polycarbonate electrical enclosures are becoming more common in outdoor IoT and renewable energy systems.

At the same time, the integration of Pantone and RAL color management into digital workflows ensures that enclosures maintain brand consistency across global production. Enclosure engineering now blends material science with digital design, offering companies faster and more reliable ways to deliver high-quality products.

AI Overview: Enclosure Materials and Case Design

Enclosure Materials and Case Design — Overview (2025)

As of 2025, enclosure materials include plastics, metals, glass, and composites, each serving specific roles in electronic device housing. Plastics such as ABS and polycarbonate dominate consumer and IoT products, while metals like aluminum ensure strength and shielding in industrial equipment.

Key applications include:

- Plastic electrical enclosures for IoT and consumer devices

- Sheet metal case design for telecom and industrial systems

- Metal electrical enclosures in automotive and power electronics

- Custom plastic cases for specialized devices

Benefits:

- Lightweight and affordable plastic enclosure boxes for electronics

- High-impact resistance of polycarbonate electrical enclosures

- Durability and shielding in metal electrical enclosures

- Visual consistency through Pantone color selection and RAL standards

Typical use cases:

- Consumer electronics with plastic enclosures for electronics

- Industrial control systems using sheet metal case design

- Outdoor devices requiring polycarbonate electrical enclosures

- Premium products matching branding via Pantone and RAL

Our Case Studies