Energy

Storage

Energy Storage Systems: Utility, Commercial, and EV Solutions

Roman Shuliankou,

Head of Industrial Automation Unit at Promwad

BESS Categories

Front-of-the-meter (FTM)

Utility grid and generation:

- Power smoothing to control ramp rates and stabilise intermittent energy flows

- Black start capability to provide backup power and restart the grid after blackouts

- Frequency response that quickly counters frequency deviations using stored energy

- Voltage regulation to balance voltage fluctuations by injecting or absorbing power

Commercial and industrial grid:

- Backup power for EV charging stations and data centres

- Optimisation of solar PV self-consumption

- Peak shaving to reduce demand charges and increase grid independence

Behind-the-meter (BTM)

Residential storage:

- Integration with rooftop PV, smart homes, microgrids, and EV charging infrastructure

- Storing energy during off-peak hours for use during peak demand

Energy Storage System (ESS) Configurations

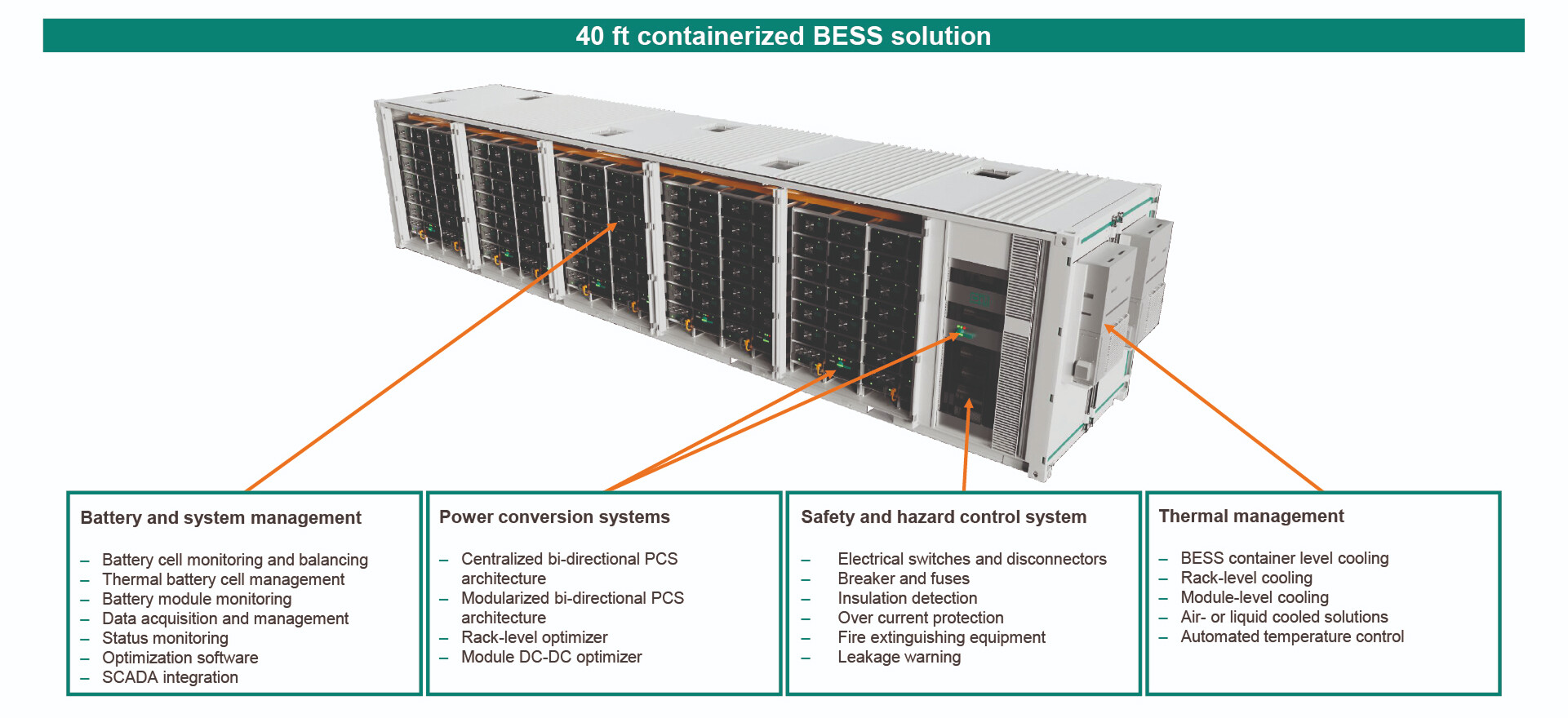

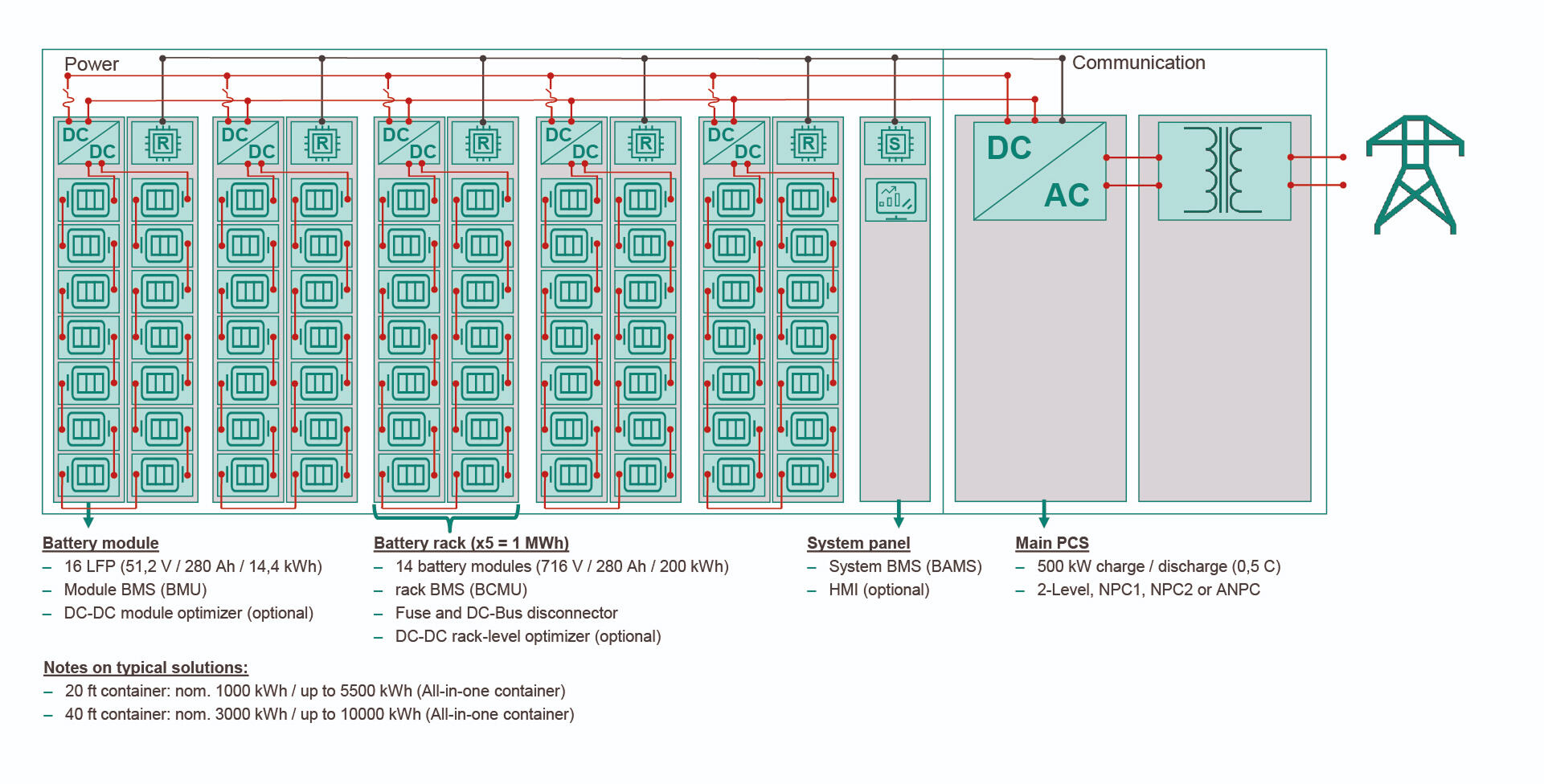

Utility-Scale BESS Architecture: Fully Integrated Turnkey Systems Comprising Multiple Functional Blocks

BESS architecture

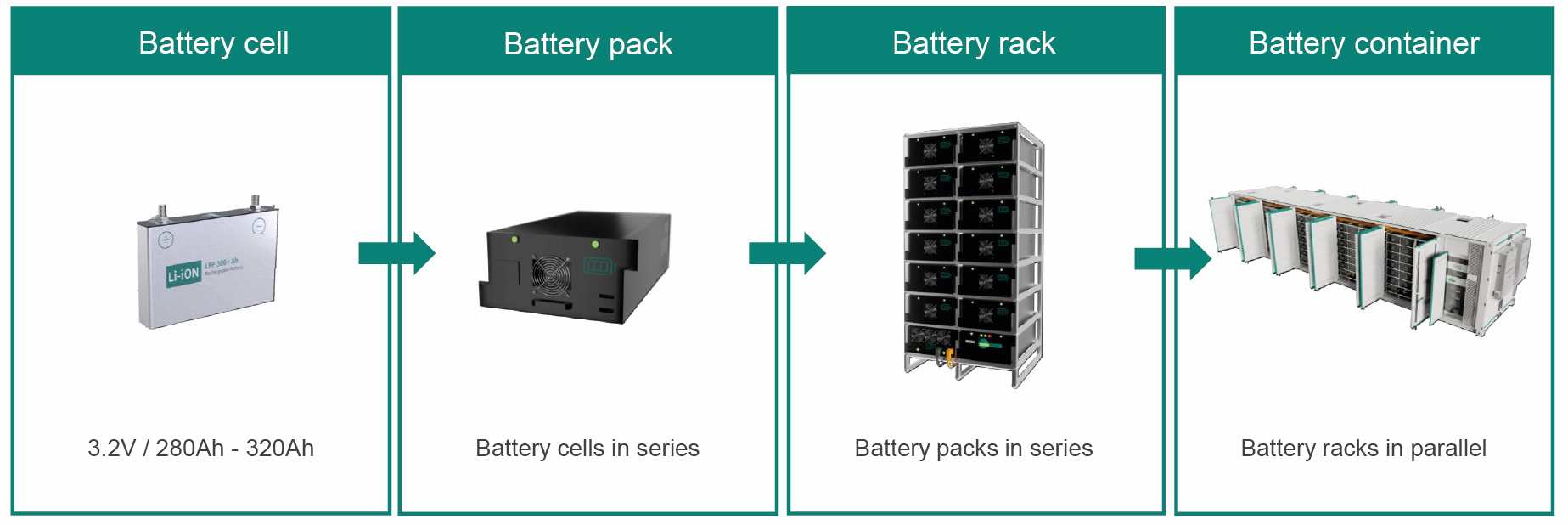

We design scalable energy storage system architectures at every level, from battery cell connections to complete container integration. Our solutions optimise voltage, energy capacity, and system reliability to meet your manufacturing requirements.

Example of a typical 20 ft energy storage system container solution

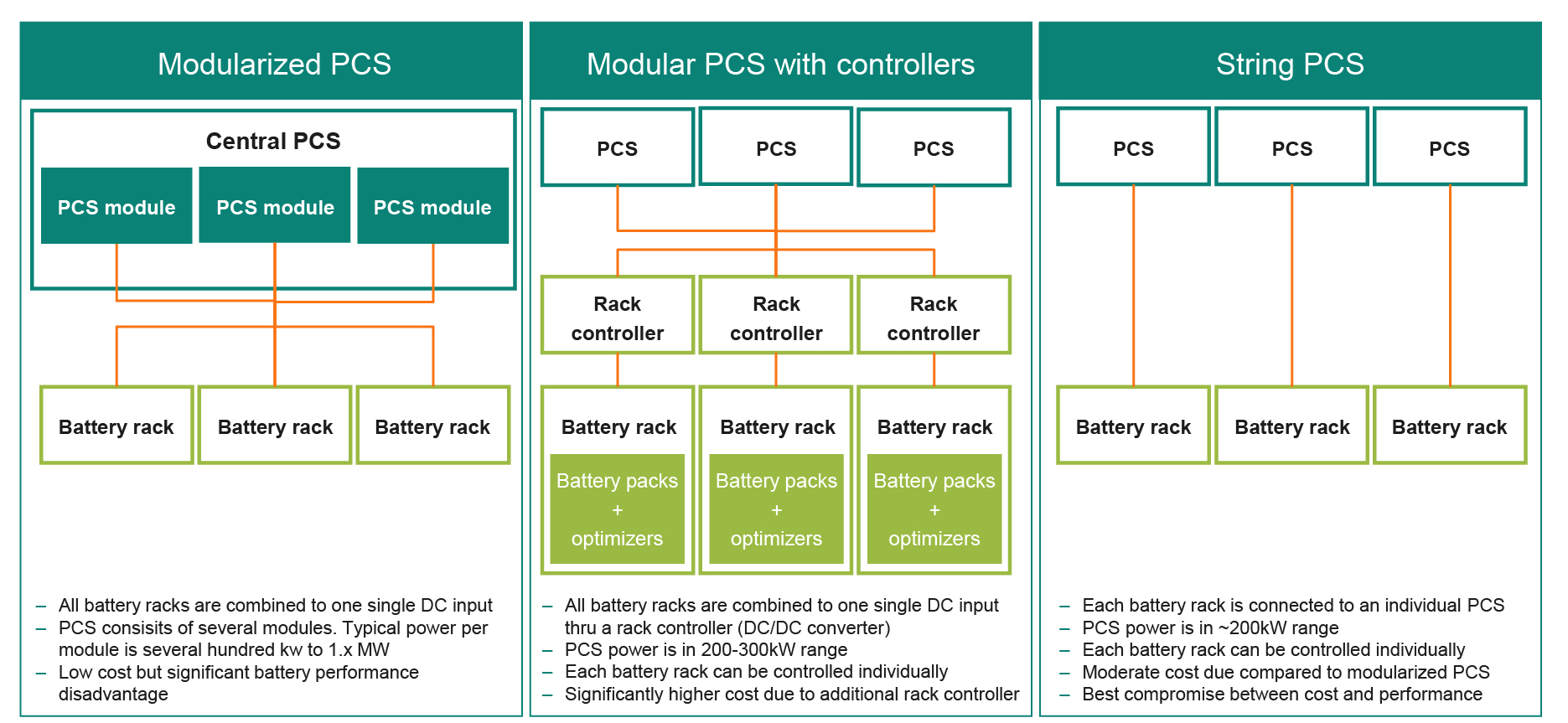

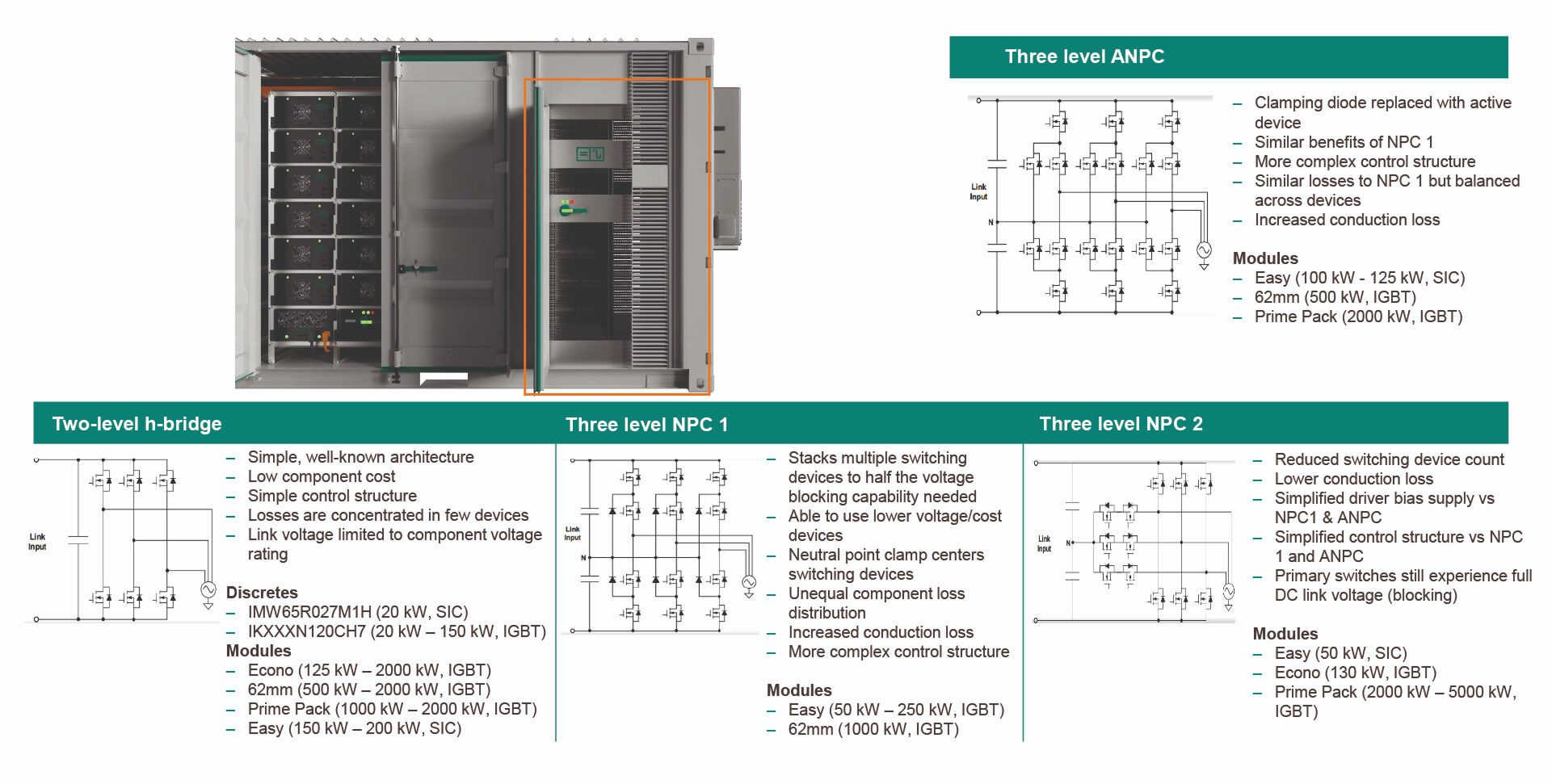

Types of Power Conversion System (PCS) Architectures

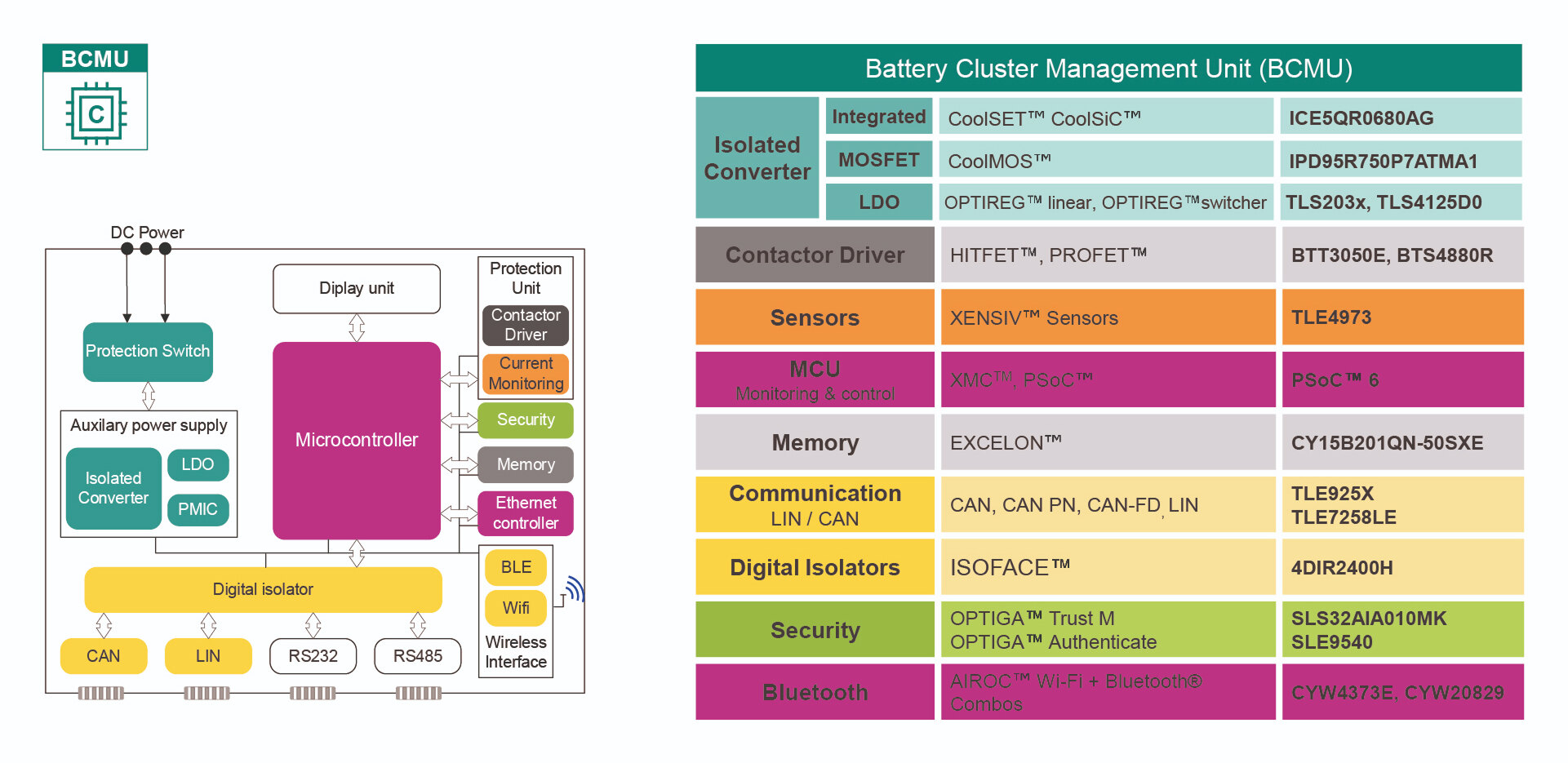

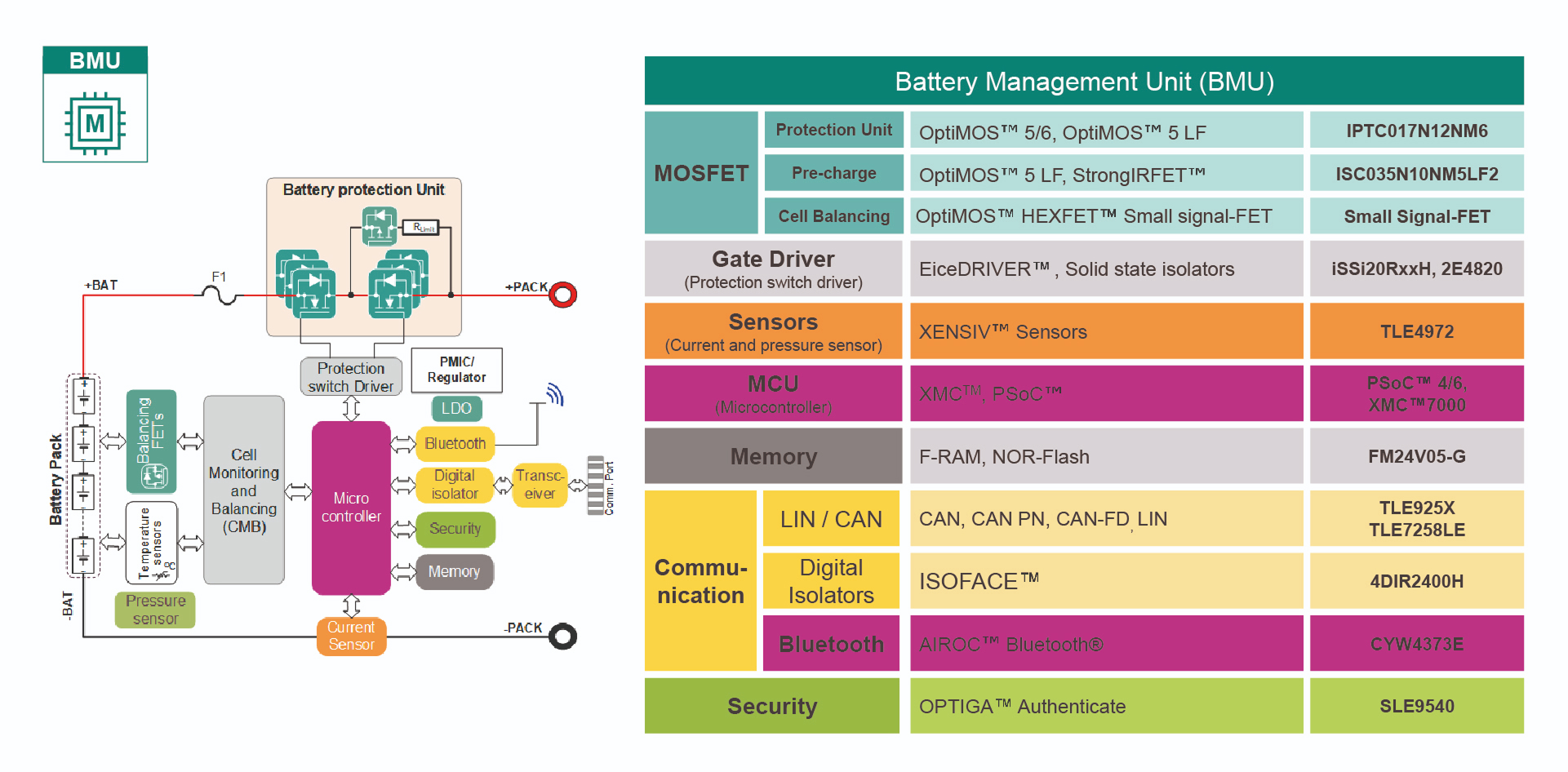

Battery and system management

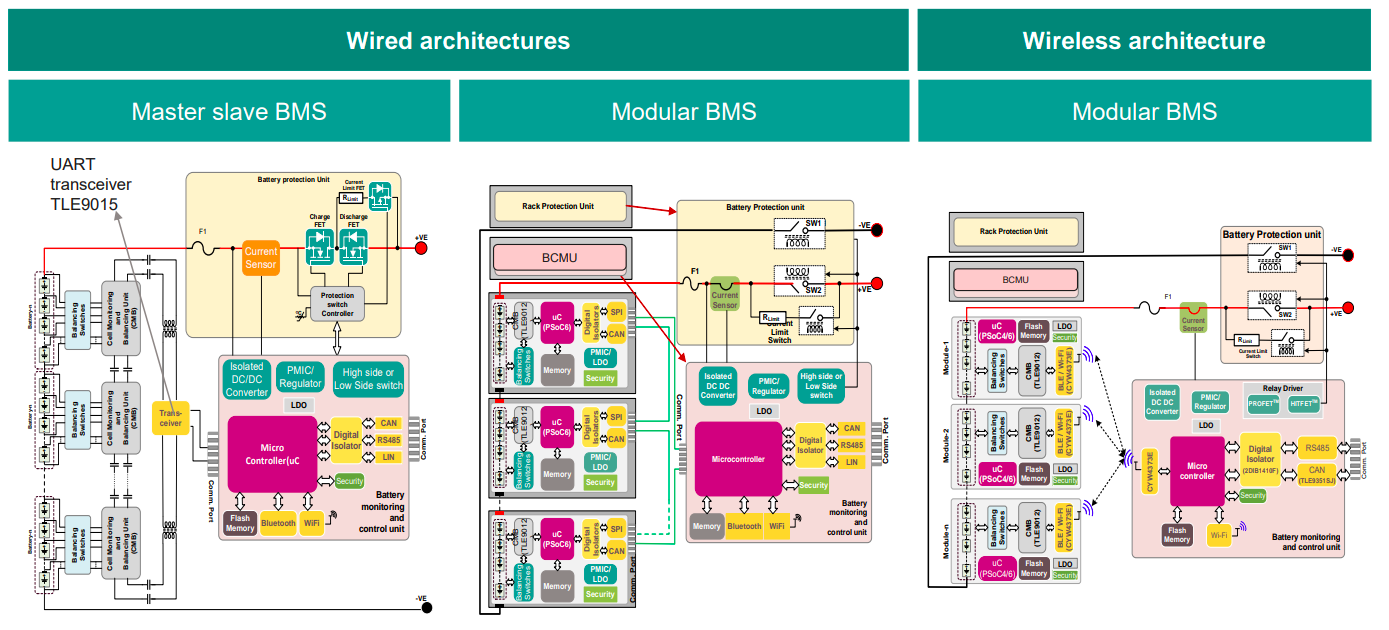

The three-layer battery management system (BMS) architecture comprises a battery array management unit (BAMU) as the primary controller, a second-level battery cluster management unit (BCMU), and a third-level battery monitoring unit (BMU). It delivers high-precision analogue signal detection, fault alarms, data logging, battery protection, parameter configuration, cell balancing, state-of-charge calibration, and high-quality communication with other system components.

BCMU

BMU

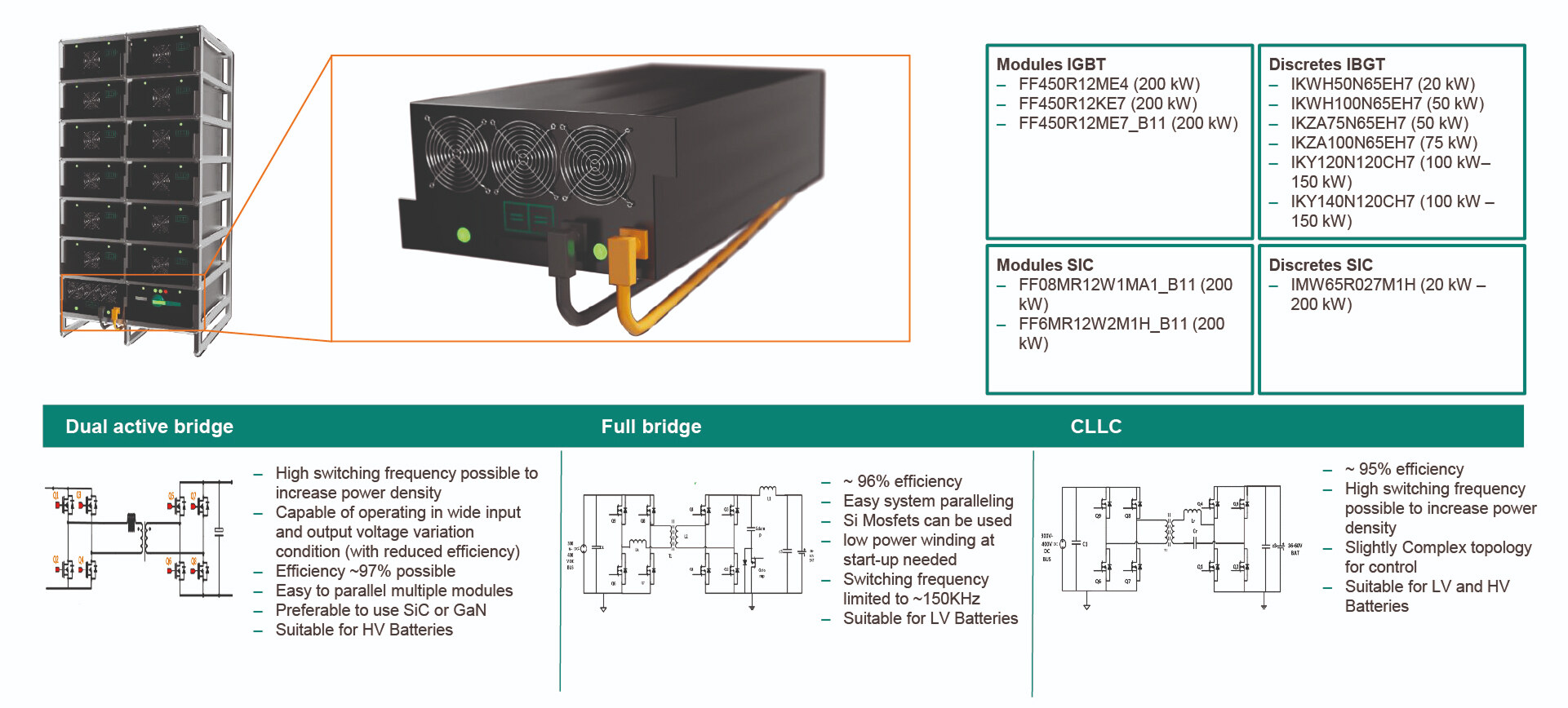

Power Conversion System (PCS)

We support both centralised and modular PCS topologies, from high-power central PCS units to distributed string PCS architectures. Additional DC-DC converters can be integrated at rack (RLO) or module level (MLO) to optimise charge/discharge cycles. AC/DC string topologies are built into the battery rack.

Central PCS: integrating into the battery cabinet or delivering as a stand-alone solution

DC/DC optimiser topologies: module- and rack-level

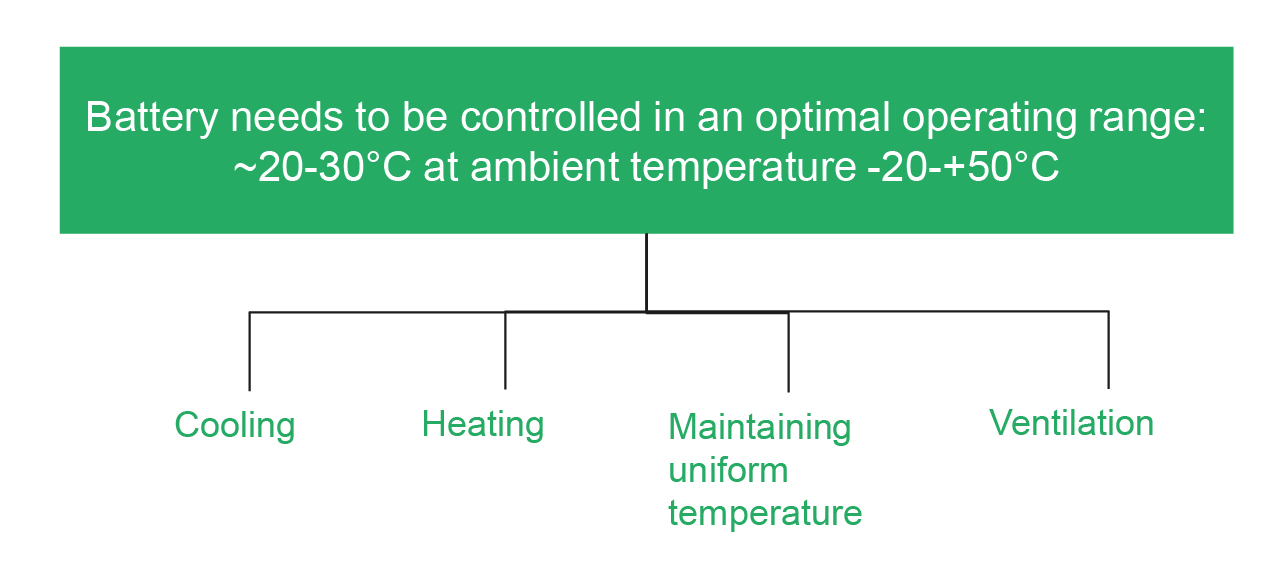

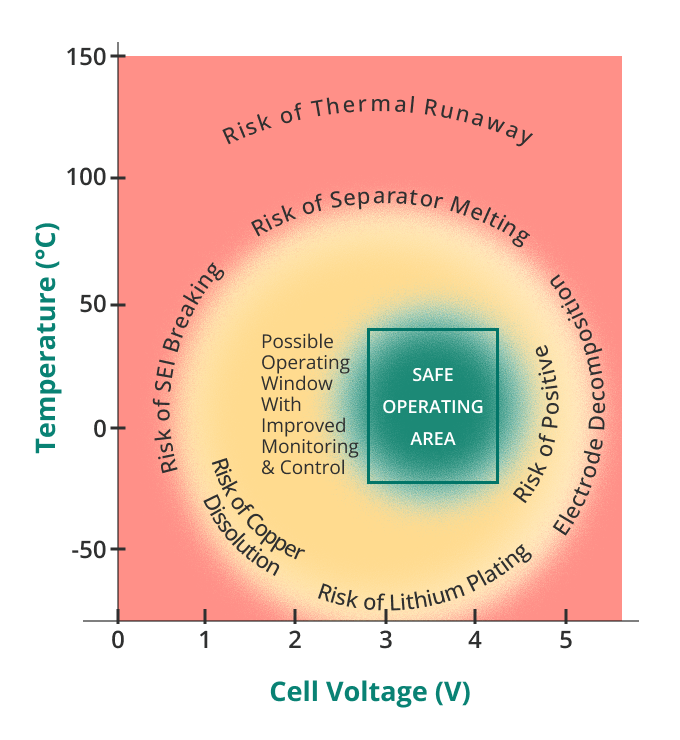

Thermal Management

Cell performance is highly sensitive to temperature, making thermal design a critical factor in battery energy storage systems. The optimal thermal strategy depends on:

- Frequency of use

- Application type (grid-forming or grid-following)

- Installation conditions (altitude, climate)

- Operational and maintenance costs (OPEX)

We develop custom thermal management solutions, including air, liquid, or hybrid cooling, as well as integrated heating systems for low-temperature environments. PCS can be installed at either the container or rack level, depending on design requirements.

NMC Type Cells

Safety and Hazard Control System

Each lithium-ion cell in a battery pack stores significant energy, meaning any malfunction can jeopardise the entire BESS and nearby equipment. Robust safety design is essential at every system level to prevent damage and ensure operational reliability.

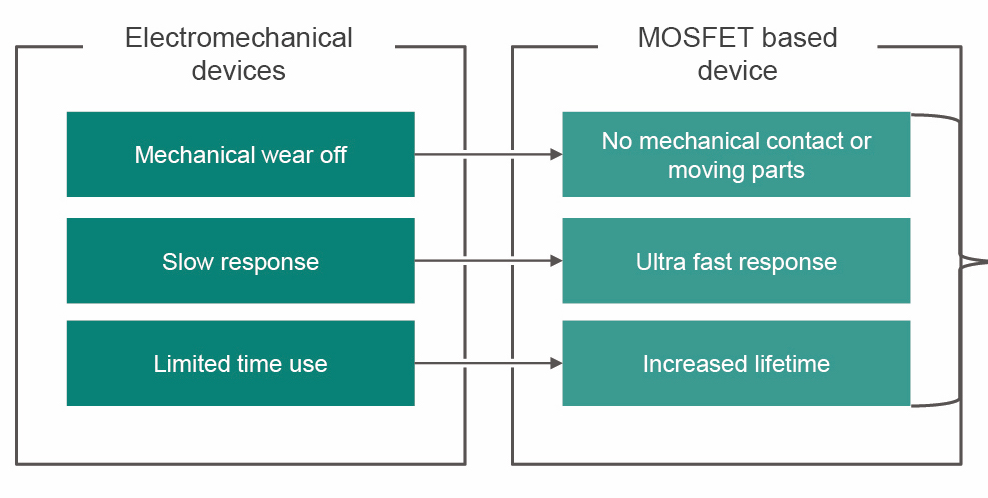

To protect against faults, BESS incorporate key circuit protection elements, such as fuses, DC breakers, and contactors. They enable rapid, controlled shutdowns during abnormal events, minimising risk and downtime.

Discover Our Case Studies

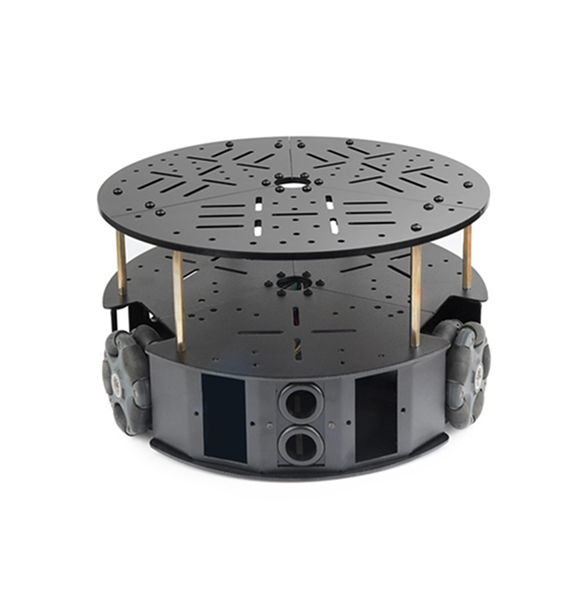

BMS Development for Mobile Robot

We developed a customised battery management system (BMS) for a mobile robot. Our scope covered schematic and PCB design, alongside comprehensive firmware engineering.

Key features:

- NXP S32K142 EVB handling supervisory functions such as state-of-charge (SoC) estimation, contactor control, isolation monitoring, fault detection and recovery, thermal management, and current/power limiting

- MC33771BSPI battery cell controller supporting 8 cells for measurement, diagnostics, and cell balancing

- NXP MC33664 TPL transceiver managing seven power conversion systems (PCS)

- Real-time operating system: FreeRTOS and Board Support Package (BSP)

- Battery protection covering overcurrent, under/overvoltage, temperature limits, cyber security, and charge/discharge control

- Compliance with UL 1642, UL 1741, UL 1973, UL 9540, UN 38.3, and IEC 62109-1 safety and quality standards

Energy Management System (EMS)

Our team engineered a smart EMS that offers real-time visualisation of electrical parameters and enables users to monitor, analyse, and optimise energy consumption. By identifying inefficiencies and balancing loads, the system helps reduce costs and minimise energy losses. All data is securely stored in the cloud and accessible anytime.

Technologies used: Java, TypeScript, JavaScript, HTML, CSS

Our Cooperation Models

Flexible approach to suit your current needs

Dedicated Team

We will form a team to fit your specific engineering task. You are free to manage it and provide additional resources.

Project-Based

We can join you at any stage or take on the entire project, including our management and risk control.

Fixed Price Model

This contract fixes the price so that it does not depend on resources used or time expended by our engineering team.

Time and Material

A T&M contract is the best option for your flexible set of tasks that are difficult or impossible to fix and assess in advance.

Looking to accelerate your BESS development with expert engineering support?

Drop us a line about your project! We will contact you today or the next business day. All submitted information will be kept confidential.