Prototyping

Prototype Development Services

As a prototype design company, we provide efficiency, cost optimisation, and guaranteed results. Each project involves the creation of three to ten prototypes tailored to your specific business objectives — whether you want a white-label solution or development from scratch.

What is Electronic Prototype Manufacturing

Electronic prototype manufacturing refers to the process of producing small-scale quantities of your future custom device for testing, validation, and refinement. The product’s samples help you accomplish the following tasks before the initial batch is manufactured:

- Demonstrate the product at shows and present it to investors

- Test hardware and software

- Test the product’s ease of assembly

- Compare and select materials (tactile sensation, appearance, etc.)

- Complete precertification testing (durability, climatic conditions, etc.)

- Perform electromagnetic compatibility (EMC) analysis

Our Product Prototype Development Services

Promwad is ready to be your electronic prototyping company, taking over all your manufacturing needs:

What We Use to Develop Your Electronic Prototype

Launching your project with our prototype development company gives you access to the following technologies:

- Milling on machines with programmed numerical control (PNC)

- Stereo Lithography and Stereo Lithography Apparatus (SLA)

- Selective Laser Sintering (SLS)

- Fused Deposition Modeling (FDM), based on extruding a polymeric filament and laying it down in layers

We choose diverse materials and their combinations within our electronics prototyping services:

- Various types of plastic: PC, ABS, PA, PP, etc.

- Polyformaldehydes and polyamides (POM, PA) for enclosures resistant to shock and corrosive environments

- Metals: various grades of stainless steel, aluminium, aluminium-magnesium alloys, etc.

- Different types of wood and other unconventional materials

- Rubber

- Glass

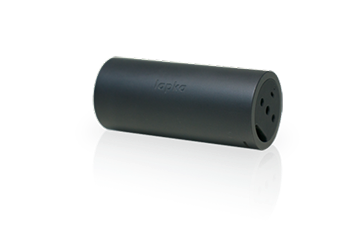

Our Сase Studies in Manufacturing Support & Electronic Prototype Development

Do you need a quote for the sample production of your electronic devices?

Drop us a line about your project! We will contact you today or the next business day. All submitted information will be kept confidential.