Electronics for hydrogen solutions

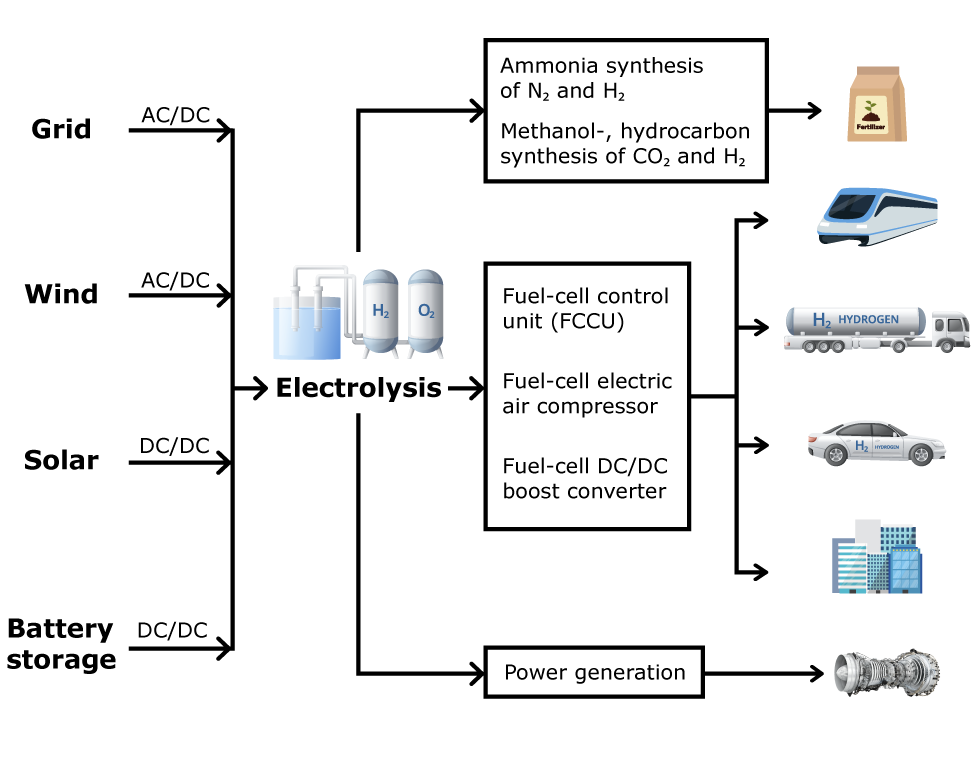

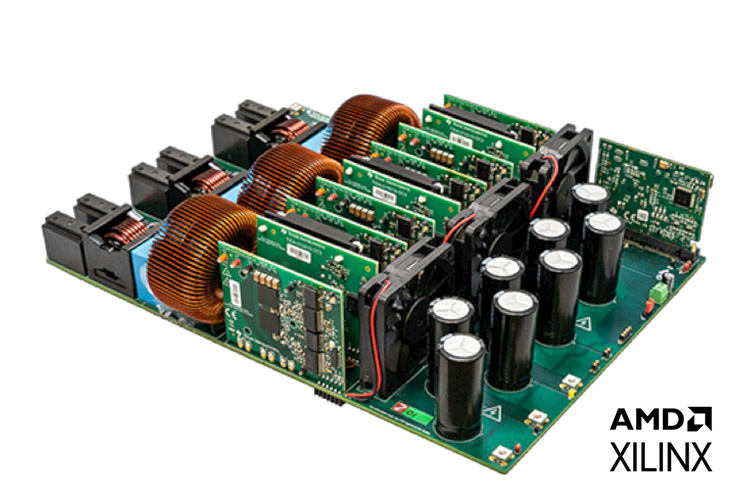

Development of embedded and control systems for safe, reliable, and scalable hydrogen generation, supporting industrial applications and renewable energy integration.

- Zero air generators

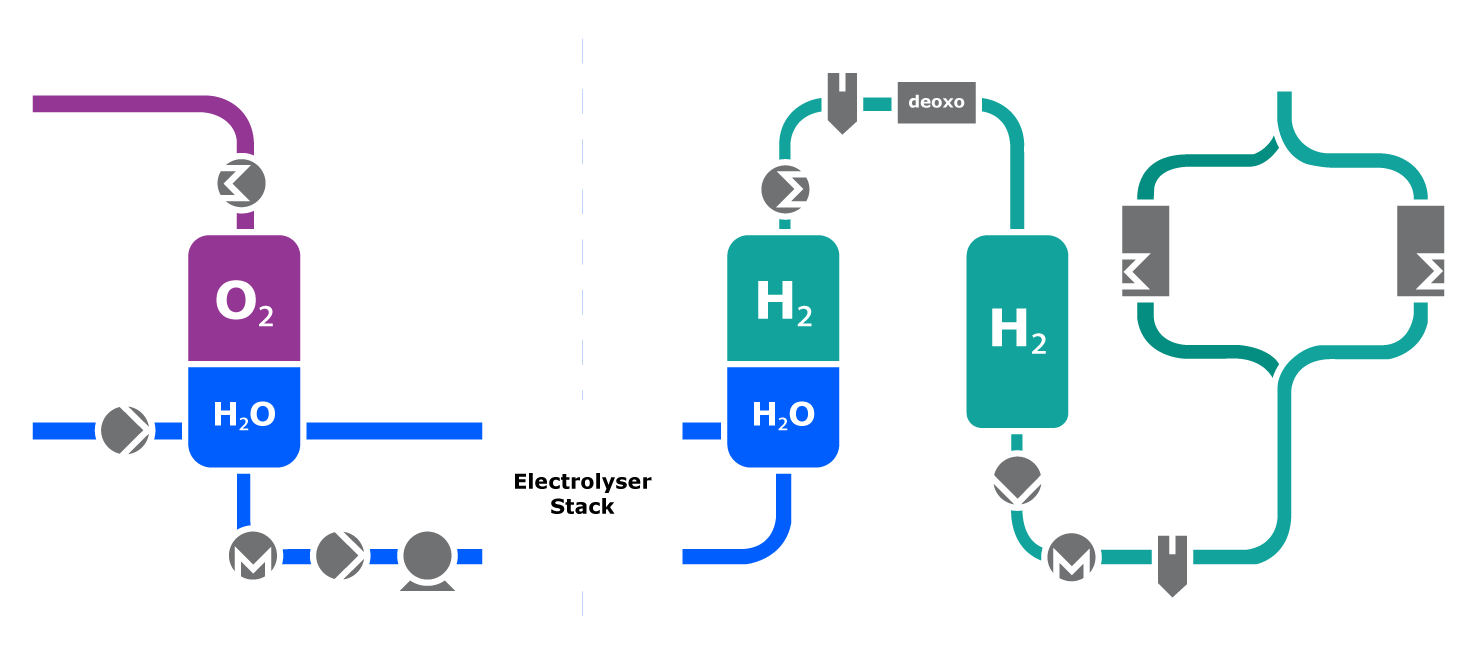

- Hydrogen electrolysers

- Nitrogen gas generators

- Gas generators for laser

- Combined gas generators

- Electrolysers