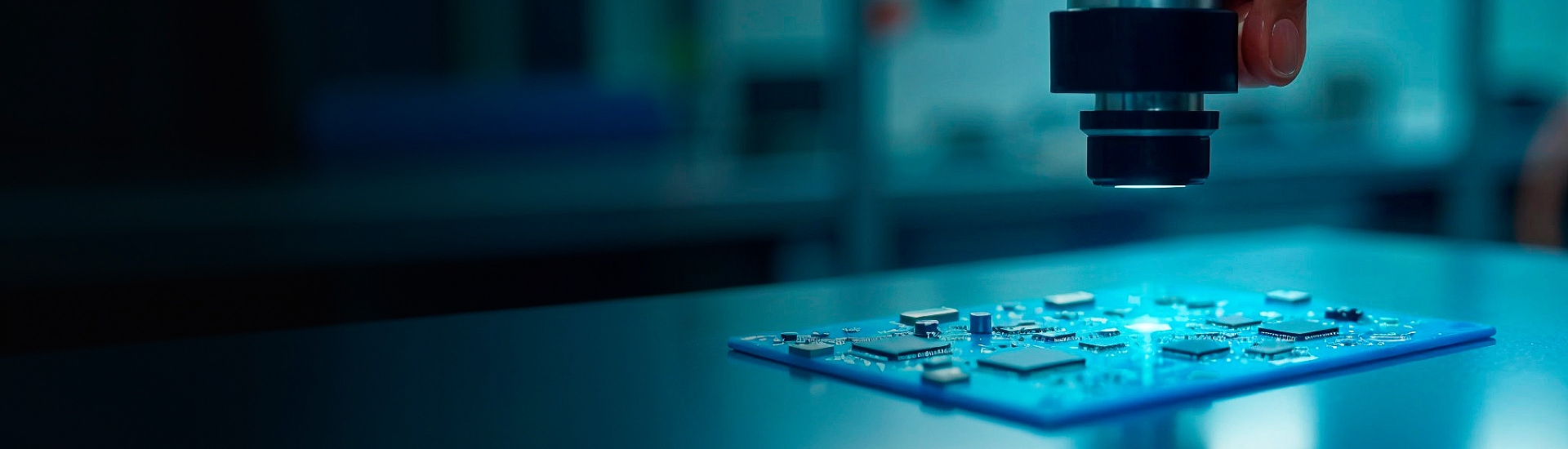

Machine Vision

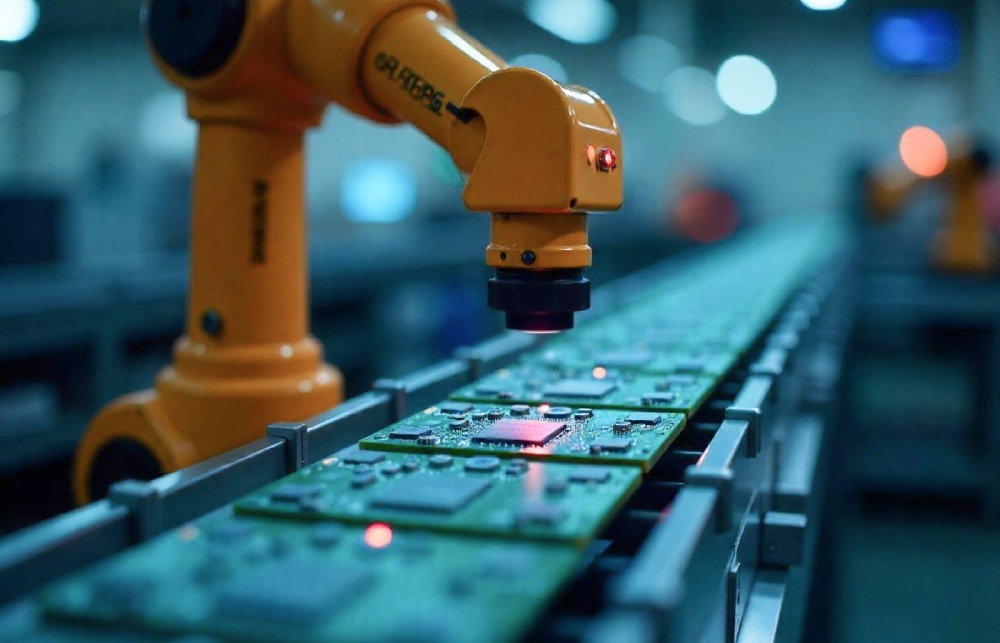

Machine Vision Solutions: Precision and Efficiency for Your Products

Build custom machine vision solutions with Promwad to optimise industrial processes and ensure real-time monitoring for consistent production.

Hardware Solutions

Learn more

Software Solutions

Learn more

Explore Our Expertise in Industrial Vision Software Development

- Vision-guided robotics and automation

- AI-powered defect detection and quality control

- Autonomous vehicle navigation and smart logistics systems

- High-precision mapping and localisation for autonomous systems

- AI-driven crop monitoring and agricultural analytics

- Deep learning for medical image segmentation and analysis

- Intelligent surveillance and real-time threat detection

- Construction site monitoring and progress tracking.

Roman Shuliankou,

Head of Industrial Automation Unit at Promwad

Solutions We Develop

Part Identification, Serialisation, and Traceability

Our team engineers vision systems that deliver precise part identification and serial tracking, vital for maintaining control and compliance in regulated industries. This solution facilitates serialisation and traceability across the production process.

Features:

- Accurate identification via 1D/2D code reading, including QR codes and barcodes

- OCR for flexible reading of text in diverse fonts

- End-to-end traceability for automotive, pharmaceutical, and food sectors.

Quality Inspection and Position Sensing

We build quality inspection systems that verifies component alignment, ensures assembly accuracy, and validates print quality, labels, and closures.

Features:

- Precise detection of position and rotation for correct assembly

- Fill level checks within tight tolerances for quality controls

- Verification of print accuracy, label integrity, and secure packaging.

Domains We Serve

and infrastructure

Retail and supply

chain management

Autonomous vehicles

and transportation

Industrial manufacturing

and automation

![]()

Agriculture and

precision farming

Security and

surveillance

Healthcare

Energy and utilities

Key Tools We Integrate

![]()

Region of Interest (ROI)

![]()

Pattern matching

![]()

Coordinate transformation

![]()

Circle, edge,

and blob finder

![]()

Brightness and

colour check

![]()

Data matrix and

bar code readers

![]()

Optical Character

Recognition (OCR)

Camera Protocols for Industrial Vision

GigE Vision

Provides high-speed, long-distance image transmission over Ethernet, enabling reliable and fast data transfer for robust, real-time industrial vision systems.

USB Vision

Offers simple integration with high data transfer rates, making it ideal for cost-effective, scalable solutions in industrial applications.

AI-Powered Solutions with NVIDIA Technologies

Employ NVIDIA's tools to develop AI-driven solutions for machine vision, intelligent video analytics, and autonomous systems.

- NVIDIA Jetson: We integrate NVIDIA Jetson to guarantee optimised AI-driven vision processing. Its compact form and energy efficiency make it ideal for deployment in industrial environments.

- NVIDIA Deep Learning AI: With pre-trained models and deep learning frameworks, our clients accelerate AI model training and inference to enhance defect detection and quality assurance.

- NVIDIA Metropolis: Metropolis enables us to deliver scalable, real-time video analytics for smart cities, manufacturing, and retail environments, improving safety and operational oversight.

- NVIDIA TensorRT: Using TensorRT, a high-performance deep learning inference library, you can improve the speed of AI models and establish high throughput in real-time applications.

Benefits of NVIDIA-Based Solutions for Computer Vision

High performance

Accelerate image processing with high-performance GPUs, SDKs and AI, ensuring immediate responses.

Scalability

Scale from edge devices to clouds and data centres with NVIDIA's flexible platforms.

Precision

Use NVIDIA's production-ready tools for accurate object recognition, defect detection, and scene analysis.

Flexibility

NVIDIA SDKs function together, enabling complete analytics and insight extraction from large visual datasets and analytics.

Discover Our Expertise in Machine Vision Hardware Development

- Interface development for various systems

- Multi-camera integration and synchronisation

- NVIDIA platform optimisation and Time-of-Flight (ToF) sensor integration

- LiDAR and hyperspectral imaging solutions

- Hardware acceleration for video processing tasks.

Andrei Smirnov, Head of the Adaptive Computing Systems Unit at Promwad

Solutions We Build

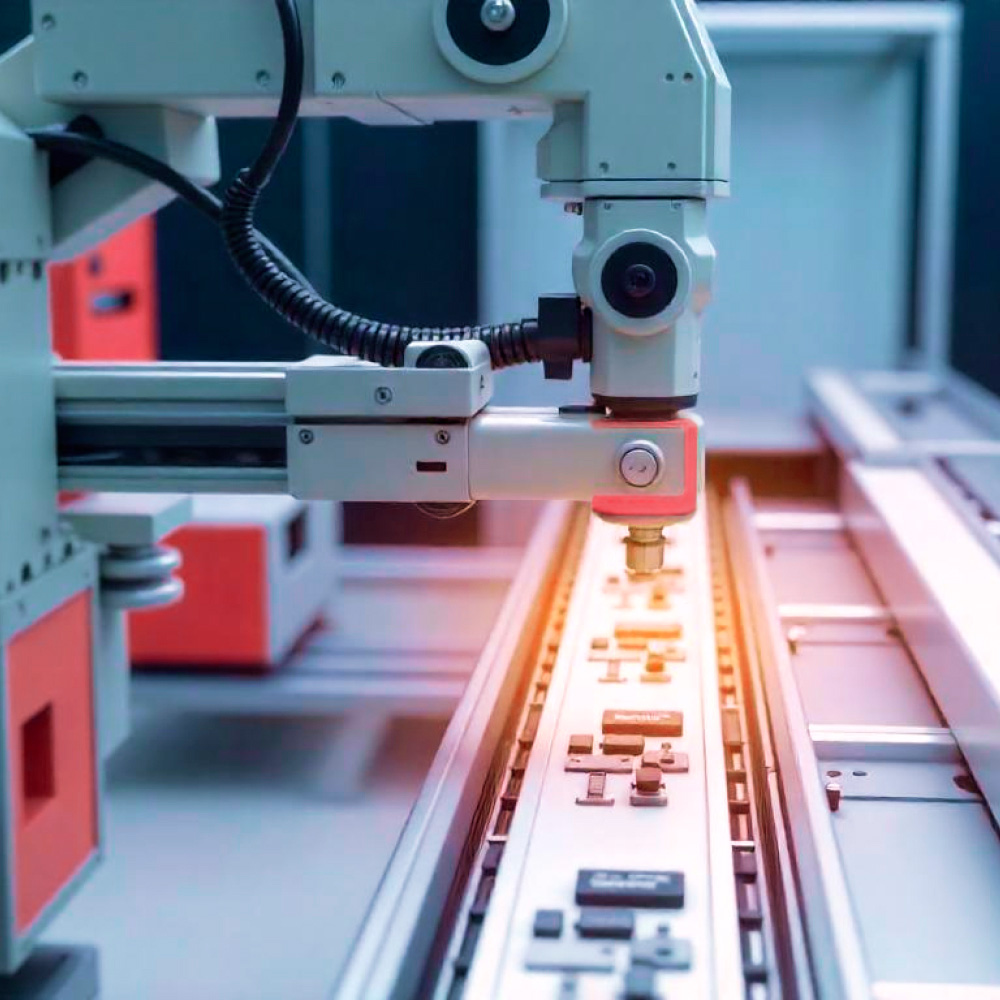

Camera-Based Sorting and Assembly

We develop sorting systems that identify and remove improperly oriented or defective components before they enter the final assembly to guarantee that only high-quality, correctly oriented parts proceed down the line.

Features:

- Automated orientation and quality inspection for assembly components

- Defect removal using blow-out nozzles to maintain quality standards

- Effective handling of critical elements like electrodes and transparent display parts

Sensor Solutions

- Vision systems: Complex image processing tailored to specific customer requirements.

- Event cameras: Designed for continuous operation, capturing and buffering video before and after triggered events, ideal for error analysis and 24/7 monitoring.

- 3D camera vision sensors: Ideal for goods inspection on conveyor belts or robotic pick-and-place tasks, offering high-precision 3D point clouds with stereo vision or time-of-flight (ToF) technology.

- 2D camera vision sensors: Versatile for applications like positioning, tracking, and feature recognition, bridging the gap between simple 2D sensors and advanced vision systems.

- Laser profile sensors: Deliver precise detection and monitoring, effective even with variable surface structures, colors, and contrast levels.

Cameras

Our team designs and engineers hardware solutions for a wide range of imaging solutions, including:

- 1D line scan and TDI cameras

- 2D area scan devices

- Infrared imaging equipment

- Microscopy imaging tools

- X-ray imaging solutions

- Smart vision systems

- Spectroscopy imaging tools

- Spherical imaging technologies.

Application Areas

![]()

People counting

![]()

On-camera inference

![]()

Barcode scanning

![]()

Non-destructive

testing

![]()

Identification and

measurement

![]()

Mobile mapping

and positioning

![]()

Embedded vision

systems

![]()

Flaw detection

and verification

![]()

Display and flat

panel inspection

Industries We Serve

Postal and logistics

Food and packaging

Semiconductor

General

manufacturing

Battery and

electronics inspection

Automotive

manufacturing

Print and web

inspection

Why Promwad

Cross-functional team

We offer end-to-end development of cameras for industrial automation, managing every engineering phase from initial concept to production.

Specialised expertise

Our team members bring deep, specialised knowledge to each project, ensuring optimal solutions tailored to your application.

Innovation-driven

We stay ahead of industry trends and treat every new project as an opportunity to apply and expand our cutting-edge expertise.

Our Cooperation Models

Flexible approach to suit your current needs

Dedicated Team

We will form a team to fit your specific engineering task. You are free to manage it and provide additional resources.

Project-Based

We can join you at any stage or take on the entire project, including our management and risk control.

Fixed Price Model

This contract fixes the price so that it does not depend on resources used or time expended by our engineering team.

Time and Material

A T&M contract is the best option for your flexible set of tasks that are difficult or impossible to fix and assess in advance.

Partner with us to transform your production line into a high-precision, fully automated system!

We will contact you today or the next business day. All submitted information will be kept confidential.