Power Electronics

Power Electronics Design Services

We provide comprehensive power electronics design services for low-, medium-, and high-voltage applications, using the latest advancements in MOSFET, IGBT, SiC, and GaN transistor technologies.

Whether you require customised solutions for power engineering, industrial, building automation, railway, automotive, or telecom sectors, our team can assist you at every stage, from concept to production.

Explore Solutions We Develop

![]()

Power electronics converters (DC/DC, AC/DC, AC/AC, DC/AC)

![]()

Charging units

![]()

Power supply units (PSU)

![]()

Power factor correction

![]()

Switched-mode power supplies (SMPS)

![]()

Automatic and static transfer switches

![]()

Modular multi-level converters

![]()

Neutral point clamped inverter (NPC)

![]()

Energy storage systems (ESS)

![]()

Voltage source inverters (VSI)

![]()

Active filters and compensators

![]()

Uninterruptible power supplies (UPS)

![]()

Reactive power compensation systems

![]()

Wireless power transfer systems

![]()

High-voltage DC (HVDC) transmission systems

![]()

Power electronics-based lighting solutions (e.g. LED drivers)

![]()

Traction inverter modules

![]()

Power distribution systems

Our Power Electronics Design Services

DSP and firmware development

Our engineers are highly skilled in digital signal processing (DSP) techniques and develop custom firmware for power electronics converters and other devices. We optimise parameters such as dead time and pulse-width modulation (PWM) to ensure precise control and optimal performance for your solutions.

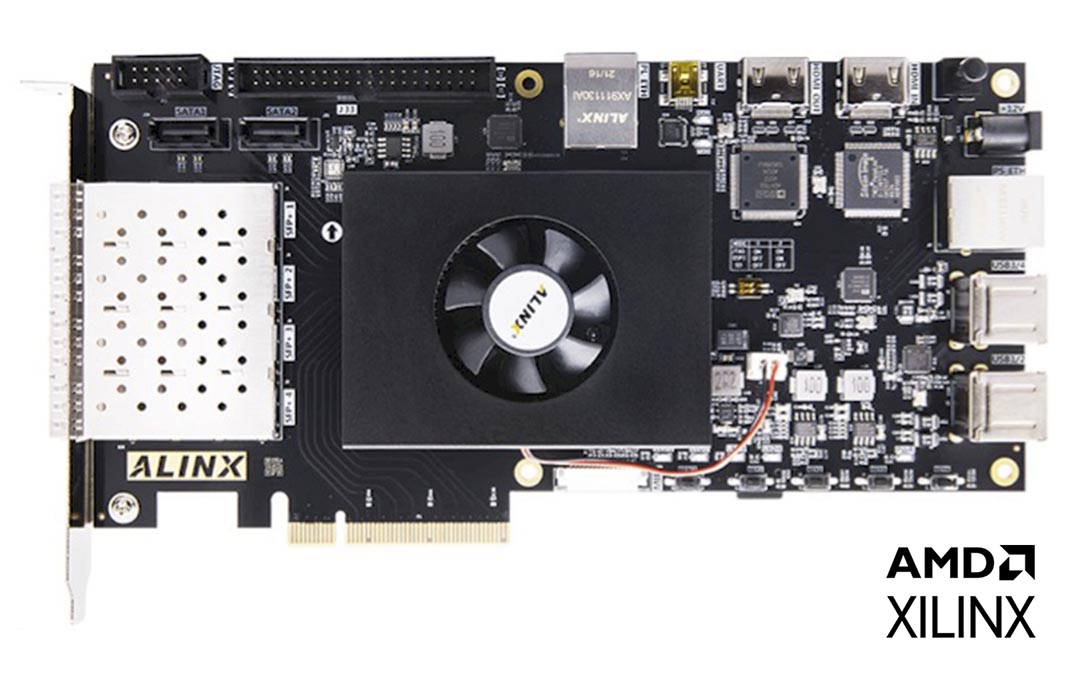

FPGA design

We design power electronics control and signal processing solutions, implementing algorithms for PWM, feedback control loops, and precise regulation. Incorporating fault detection mechanisms at the hardware level, we ensure real-time response and protection against system anomalies.

PCB design simulation

Our team uses tools like Altium Designer and Siemens PADS Professional to design and simulate printed circuit boards (PCBs). We implement controlled impedance routing, thermal vias, and layout partitioning to optimise power distribution and enhance thermal management capabilities.

Thermal simulation

Using power electronics simulation software, we assess heat dissipation, considering factors such as conduction, convection, and radiation. Our team can optimise heatsink designs, component placement, and airflow paths, ensuring reliable operation under varying load conditions and environmental temperatures.

Schematic design simulation

As a power electronics company, we use industry-leading simulation tools such as SPICE and PLECS. Our team can analyse and optimise power electronics schematics, validating key parameters, including voltage/current waveforms, transient responses, and component stress levels.

Thermal, mechanical, and EMC testing

Our testing protocols include thermal cycling, vibration testing, and electromagnetic compatibility (EMC) testing using equipment that is compliant with standards such as the IEC 61800-3 and EN 61000 series. We also ensure compliance with regulatory requirements and reliability in harsh operating environments.

Our Case Studies

4kW dual-phase LLC

We've engineered a high-performance power board (dual-phase LLC) for our Canadian client, integrating high-voltage and low-voltage power MOSFETs.

Key features:

- Dynamic control

- Efficiency controller

- The TMS320 family of digital signal processors

- Peak efficiency >98.3%

- Flat efficiency plot from 10% to 100% load

- Output voltage min/max 44 V/58 V

- Complete digital control for dual-phase LLC: phase shedding, current sharing, etc.

- Diagnosis and prevention of LLC capacitive mode and MOSFET body diode hard commutation

- User interface for parameters setting and monitoring

- PI/PID controller

- Balancer function

MMC converter

As a power electronics company, we participated in the development of algorithms for modular multi-level converter (MMC) for high-voltage direct current (HVDC) transmission.

Key features:

- Full-bridge submodules

- DSP/FPGA

- Real-time synchronisation protocol with SFP

- DC fault detection (valve overcurrent, DC pole undervoltage / voltage differential / overcurrent, and DC current differential)

- Synchronisation via IEEE1588 with limited accuracy

- Synchronisation accuracy is ±2-4 ns, ultra-fast communication

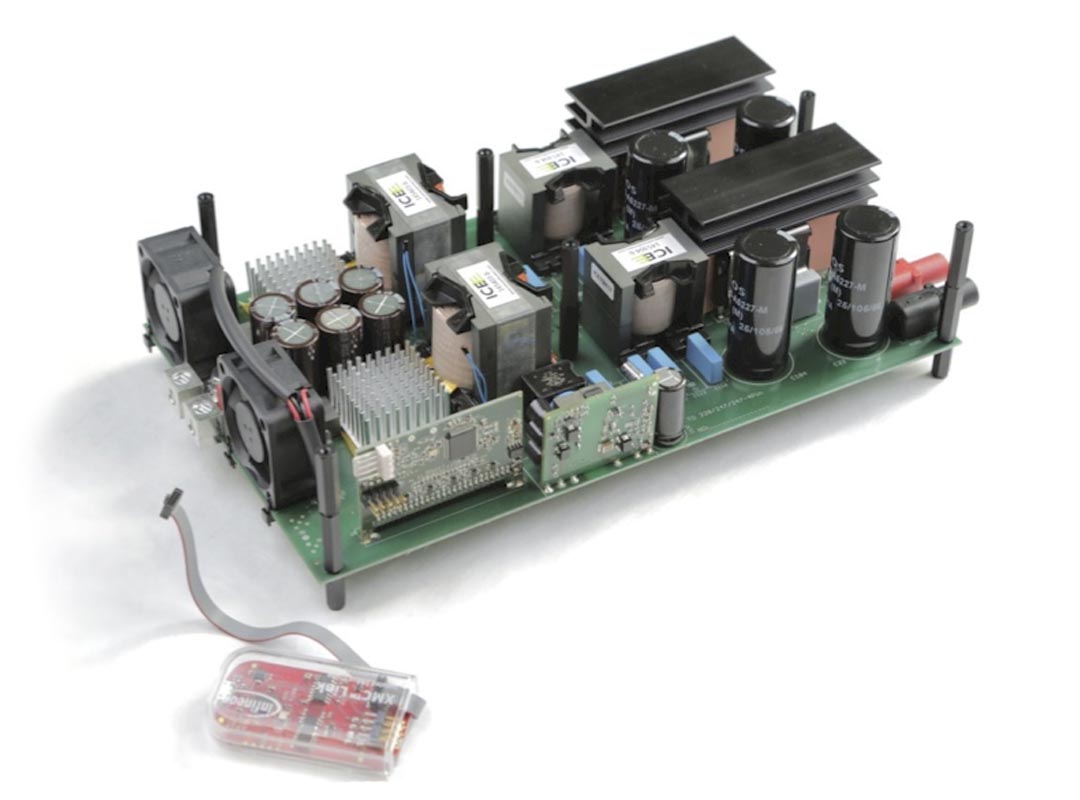

3600W LLC DC-DC demonstration board

Our 3600W full-bridge to full-bridge LLC DC-DC demonstration board efficiently converts 360V to 400VDC input voltages into a regulated 52V output, ensuring robust operation even under demanding conditions.

Powered by e-mode HEMTs, the converter ensures minimal losses at high switching frequencies, achieving remarkable power density.

Key features:

- Support for 3600W loads at 52V regulated output

- Continuous operation at 69A load

- Input range 360VDC to 400VDC

- Integrated internal cooling with a fan providing approximately 400 LFM airflow

- Soft-start for smooth power-up sequences

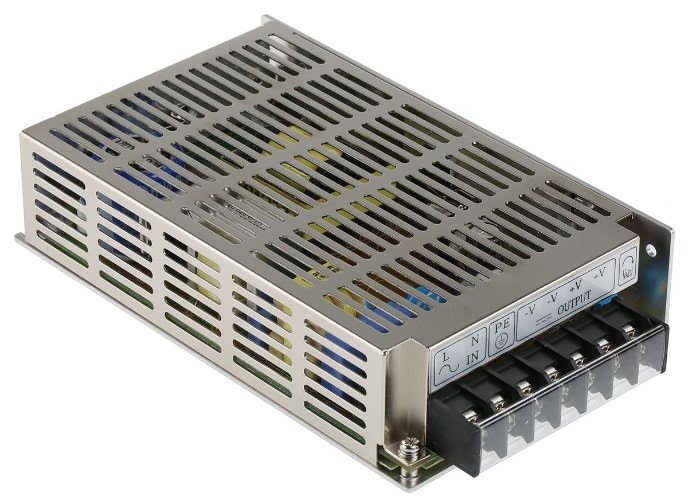

SMPS

Our engineers developed hardware and firmware for a client's project, including microcontroller firmware, DSP applications, PCB, and schematic design for an SMPS 10 kW.

Key features:

- Filter bridge

- PFC, PFC control, 100 kHz PFC PWM

- Inrush hot-plug control, ADC

- DC/DC converter control, multi-mode power control, 200 kHz PWM DC/DC

- Interface circuit, monitor MCU, aux P/S

- MCU TMS320, current/load sharing control

- Supervisory housekeeping circuits, UART, CAN

- Voltage controller, current controller – DC/DC, PFC (2p2z)

3.0kW dual LLC evaluation board

We’ve worked on a 3kW dual-phase LLC evaluation board to power the HV DC-DC stage of rectifiers and industrial SMPS.

Our solution includes state-of-the-art 600V CoolMOS C7 superjunction MOSFET in TO-220 and 150V OptiMOS 5 in SuperSO8 power devices integrated with driving and control techniques.

Key features:

- Dual-phase LLC topology with full digital control, facilitating current sharing and phase shedding

- Innovative design prevents MOSFET body diode hard commutation and LLC capacitive mode operation

- User-friendly user interface enables smooth parameter setting and real-time monitoring

Topologies We Support

Our Tech Stack in Power Electronics Design

CAD software

Altium Designer, Siemens PADS Professional

Simulation tools

LTspice, PSpice, Simulink, Qspice

Transistors and semiconductor devices

MOSFETs, IGBTs, GaN, SiC

Firmware development

C, C++, Rust, Verilog, VHDL

FPGA

AMD, Lattice, Hilsher, Renesas, NVIDIA, Texas Instruments, Analog Devices, Microchip, Intel

DSP

Texas Instruments (TI): TMS320 series, Infineon: XMC, Aurix

Testing and measurement equipment

Oscilloscopes, Multimeters, Function generators, Spectrum analysers, System power supplies

Typical operating frequencies

– 50 kHz to 120 kHz / UPS boost / Buck

– 80 kHz to 160 kHz / PFC + Boost AC/DC – Rectifier / Single / Multi-phase interleaved

– 120 kHz to 240 kHz / DC/DC (isolated) AC/DC – Rectifier / H-bridge / Full-bridge / FB-ZVS

Typical operating frequencies

– 200 kHz to 1000 kHz / DC/DC (non-isolated) DPA-Enterprise / Single-phase buck / Multi-phase interleaved

– 1 MHz to 4 MHz / DC/DC (non-isolated) DPA / Bricks / Single-phase buck / Multi-phase interleaved

– 10 kHz to 35 kHz / Motor control / 3-phase inverter

Libraries

Infineon

SMPS Designer — simulation tool for electronic power supply design, IPOSIM — power electronics simulation software, AURIX, MOTIX, Power MOSFET, ModusToolbox, Power management ICs (PMIC), PowIRCenter

Texas Instruments (TI)

IGBT gate driver libraries, PowerLab reference design library, WEBENCH Power Designer, SwitcherPro, Power system management, (PSM) library, PMIC libraries

Power factor correction (PFC)

3-phase active PFC rectifier | Boost-type PFC rectifier | 3-phase diode bridge rectifier | Vienna rectifier | Vienna rectifier demonstrator | 6-switch boost PFC rectifier (active boost) | 6-switch buck PFC rectifier (active buck) |

6-switch buck PFC rectifier demonstrator | Integrated active filter (IAF) PFC rectifier | IAF rectifier demonstrator | Swiss rectifier | Swiss rectifier demonstrator | ⅓ PWM boost & buck PFC rectifier | ⅓ Isolated Vienna rectifier | ⅔ PWM buck & boost current source rectifier | Trident rectifier | Y-rectifier | Y-inverter demonstrator | Boost-buck-type PFC | Buck-boost-type PFC

Power Electronics Algorithms

Maximum power point tracking (MPPT) | 3P3Z, 2P2Z, and PID controllers | Fuzzy logic controller (FLC) | Sliding mode control (SMC) | Model predictive control (MPC) | Hysteresis control | State-space control | Adaptive control

Why Promwad

In-house design laboratory

Our laboratory has cutting-edge equipment, such as high-speed oscilloscopes, spectrum analysers, and signal generators, enabling us to conduct intricate analyses and precise simulations.

Advanced technologies

We partner with leading vendors, such as Infineon, Texas Instruments, STMicroelectronics, and NXP, to enhance your power electronics design solutions with the latest technologies.

Cross-industry expertise

We seamlessly integrate principles from telecommunications, automotive, robotics, and power engineering domains into our design processes, solving unique challenges of various industries.

Our Cooperation Models

Flexible approach to suit your current needs

Dedicated Team

We will form a team to fit your specific engineering task. You are free to manage it and provide additional resources.

Project-Based

We can join you at any stage or take on the entire project, including our management and risk control.

Fixed Price Model

This contract fixes the price so that it does not depend on resources used or time expended by our engineering team.

Time and Material

A T&M contract is the best option for your flexible set of tasks that are difficult or impossible to fix and assess in advance.

Drop us a line about your power electronics design project and get a quote!

We will contact you today or the next business day. All submitted information will be kept confidential.