From Concept to Initial Prototypes of the NFC Access Bracelet — In 90 Days

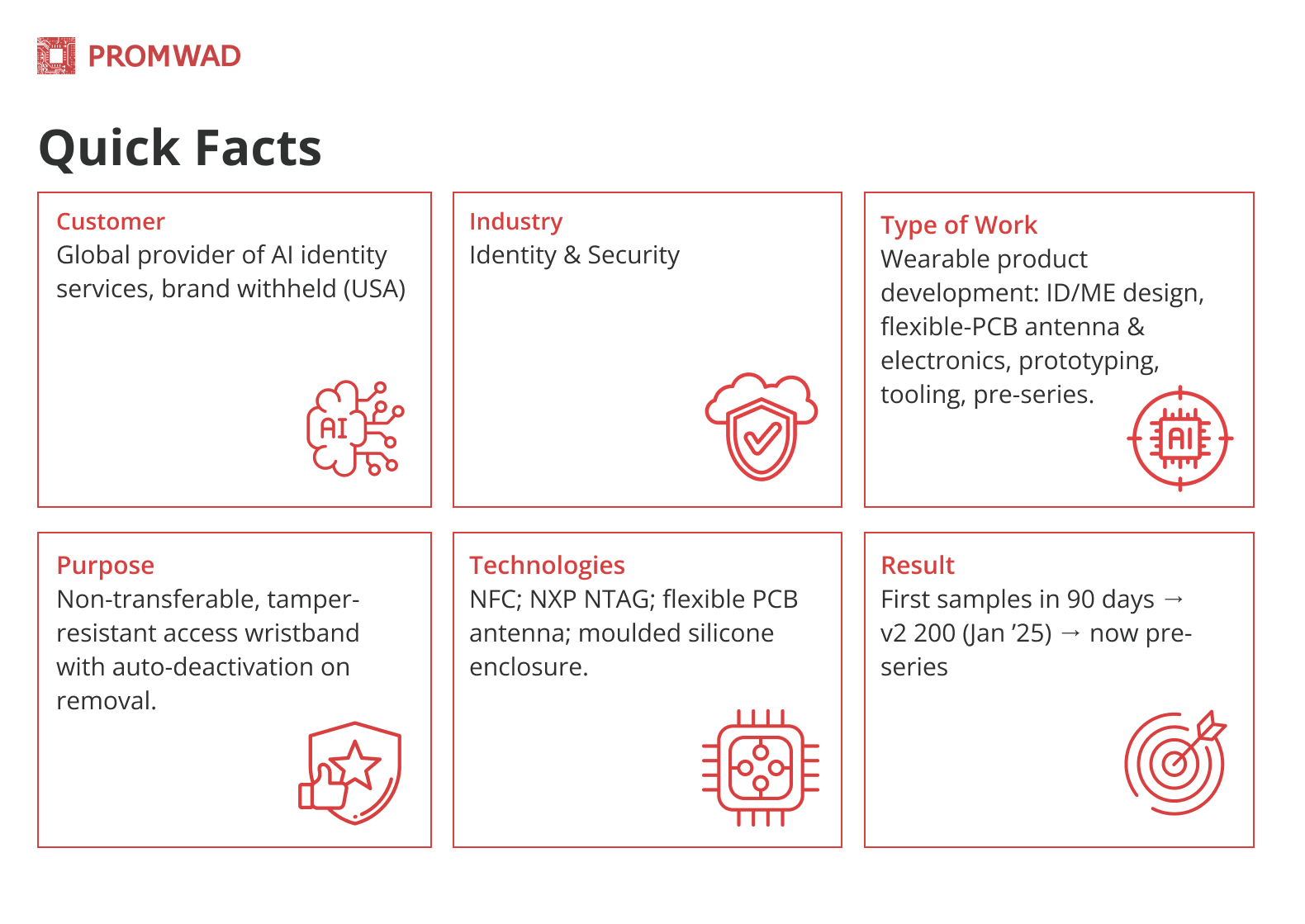

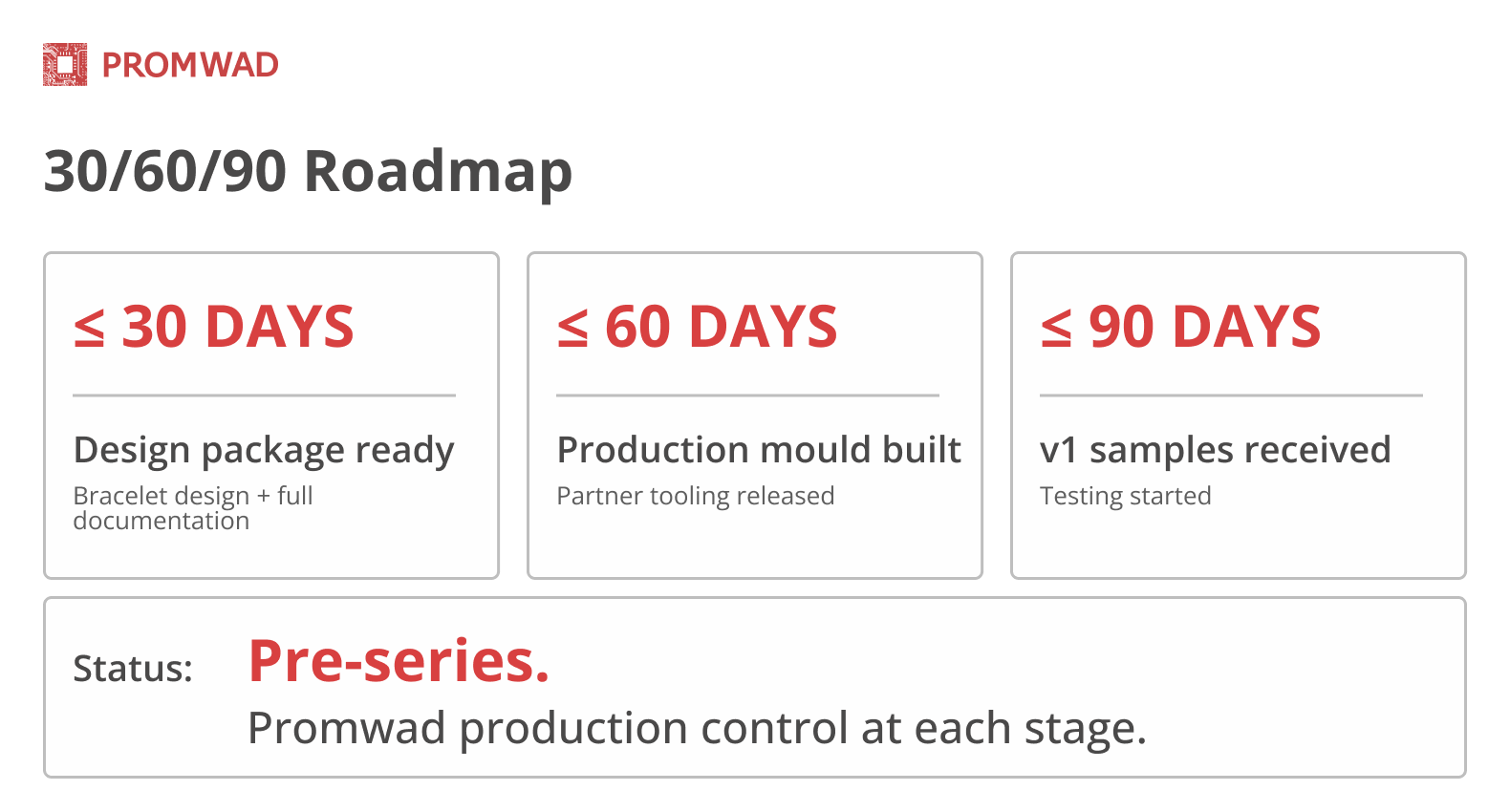

Project in a Nutshell: We engineered the industrial design, developed the electronics with a flexible antenna on an NXP platform, and prepared a molded silicone case bracelet for a wearable pass at the request of a U.S digital identification solutions provider. This is a disposable bracelet: if someone tries to remove the bracelet, it automatically stops working. We received the first samples in 90 days and began testing; the second iteration (200 units) addressed the initial comments. In the summer of 2025, our team presented a consolidated solution. The project is currently in pre-production.

Client & Challenge

Our client is a major provider of digital identification solutions based in the U.S. The company approached us to create a wearable, non-transferable NFC wristband for access control that automatically stops working when someone tries to remove it. Three factors were important to the client: speed of execution, a transparent work plan, and a single point of responsibility for the entire journey from design to pre-production.

After an unsuccessful attempt with another supplier, the client needed a predictable path to pre-production in 2025: we delivered this through reliable ID/ME design, disciplined short iterations, and single responsibility from design to prototyping.

Solution

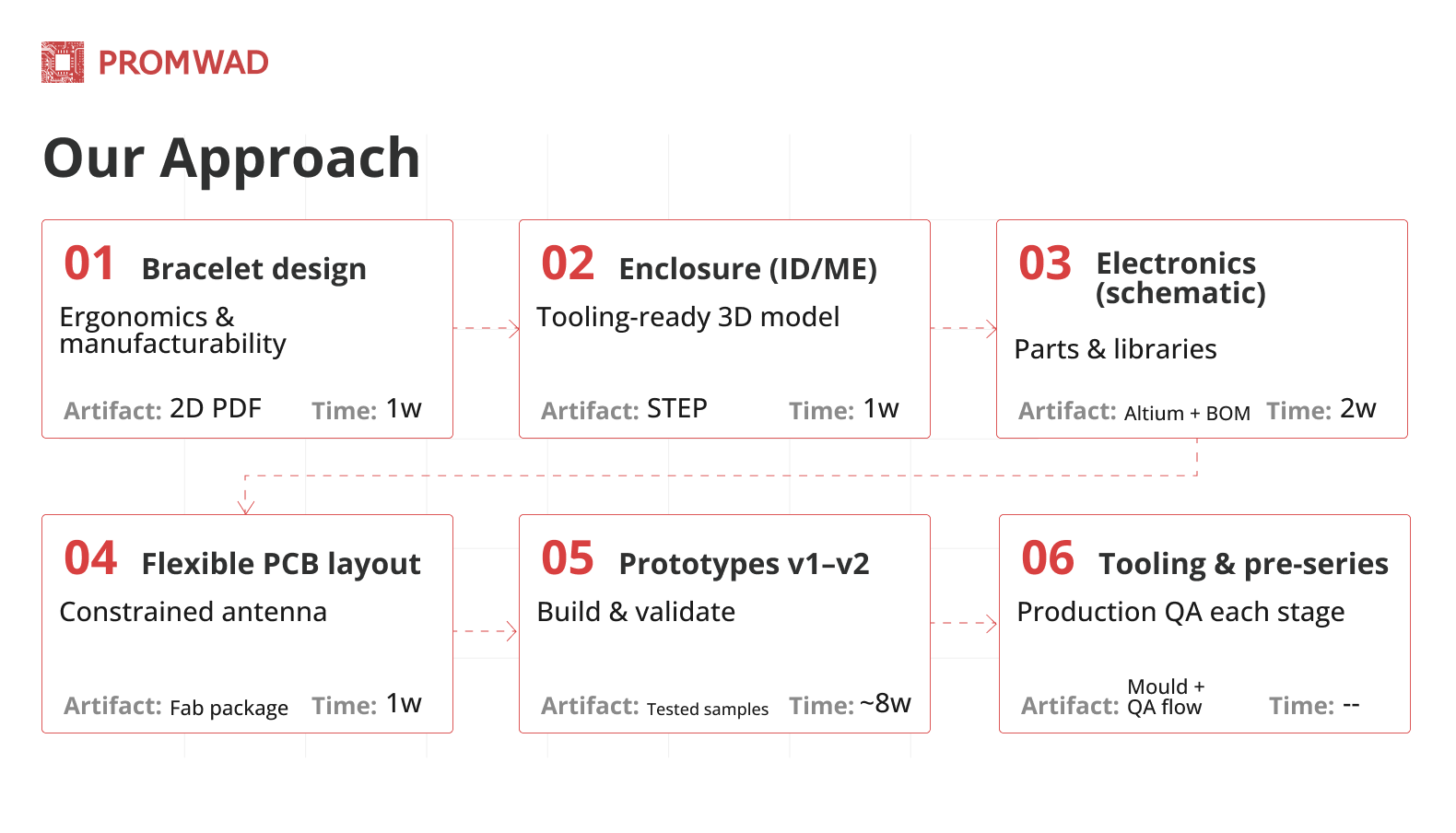

The Promwad team handled the entire device development cycle and production preparation. First, we developed the bracelet's industrial design — its shape, ergonomics, and manufacturability — to ensure comfort and stable production. Then we developed a flexible printed circuit board with an antenna and electrical connection for the NXP NTAG microchip, and then designed a molded silicone case, coordinating the geometry and tolerances for assembly and sealing.

The manufacturing part included mold making by a partner, trial batch production, and logistics. Quality control was built into every stage: from incoming material inspection and geometry verification to sample acceptance against checklists.

Software was deliberately not included in this phase: the goal was to validate the mechanics, components, and assembly, and get the product ready for pre-production.

We worked iteratively in short cycles. At each stage, we created a specific artifact — 2D concepts, then a STEP model, then a design in Altium with a BOM and a fab package. At the end of each iteration, we held a demonstration, refined the solutions, and moved on to the next stage. Planning was done weekly/biweekly with weekly status updates in a unified format; changes and risks were tracked using a shared change log.

The project manager was responsible for coordination: he linked design, mechanics, electronics, molding, and manufacturing, and also monitored deadlines and communications. The team included an industrial designer, a mechanical engineer, a schematic engineer and a PCB designer.

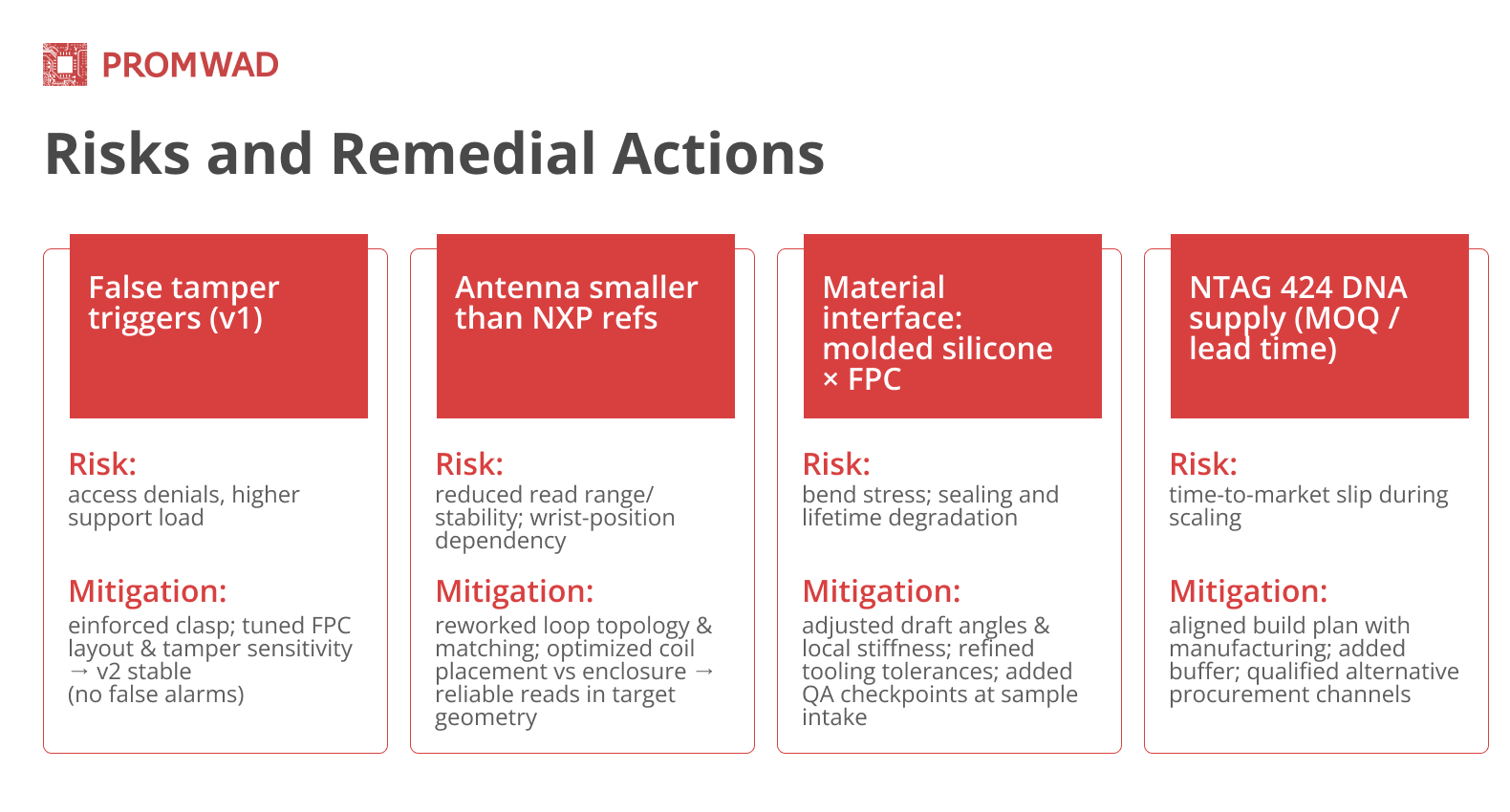

Risks and Remedial Actions

During the initial iterations and tests, we identified key risks affecting access reliability, device durability, and pre-production launch timelines. Below is information about what this meant for the business and the decisions we made.

Business Value

The client now has a consolidated solution that has undergone two iterations (v1 and v2, 200 units). The mold has been manufactured, quality control has been established, and a complete set of design documentation has been prepared for subsequent batches. This ensures pre-production readiness in 2025 and allows for scaled production with synchronized procurement of key components (NXP NTAG 424 DNA). Our client has added a new product to its portfolio: a wearable, non-transferable pass for secure infrastructure.

More of What We Do for Manufacturing

- Electronics Manufacturing Services: Explore our turnkey electronics contract manufacturing services.

- Smart Wireless Thermostats: a case study of turnkey development of a device that would pay for in two years.

- Promwad Boosts Businesses with Wearable Devices: learn how we help our clients in various industries improve efficiency with wearables, mobile apps, and data analysis.

FAQ

How do you balance ergonomics, durability, and manufacturability in a molded silicone wearable?

We co-optimize bracelet geometry, shore hardness, wall thickness, draft angles, and split lines; define bend radii around the FPC window; and specify sealing features (ribs, lips) that survive sweat/UV/temperature. We also chose medical grade steel for the production of rivets.

How do you choose and manage partners for tooling and molding?

We qualify partners on process capability (CPK), known silicone grades, class of moulds, and sampling cadence. Promwad coordinates mould design approval, T0/T1/T2 runs, and design-to-tool feedback.

What are typical tooling lead times and how do you iterate on the mould?

For the first prototypes, silicone molds are used; their production takes up to 2 weeks. For steel molds expect 3–6 weeks depending on complexity; we plan for insert changes/polishing and keep spare inserts for rapid antenna-window adjustments.

How do you tune a flexible NFC antenna in constrained geometry?

We iterate loop topology, matching network, and placement vs. enclosure, then validate read range/stability across wrist positions and environments; final tuning is reconfirmed on T1/T2 parts.

How do you de-risk reliance on a specific chip?

We maintain qualified alternates/second-source paths, add buffer stock, and pre-approve alternative procurement channels with traceability in the BOM.

AI Overview

The NFC access bracelet project demonstrates rapid end-to-end hardware development — from concept and industrial design to flexible PCB electronics and pre-series production. Promwad engineers created a non-transferable, tamper-resistant wearable pass with a molded silicone enclosure and optimized antenna geometry for reliable NFC communication.

Key Applications: Secure access wearables; digital identity devices; smart wristbands; contactless authentication systems.

Benefits: Fast prototype delivery; integrated industrial + electronic design; high reliability; production-ready documentation.

Challenges: Antenna tuning in flexible geometry; mechanical durability; material stress and sealing; component supply constraints.

Outlook: As wearable access control expands across transport, events, and enterprise security, compact NFC-based wristbands will enable safer, faster, and user-friendly identification.

Related Terms: NFC wearable development; flexible PCB antenna; ID/ME device design; tamper-detection electronics; pre-production prototyping.