High-Speed

PCB Design

High-Speed PCB Design

High-speed PCB manufacturing and design at Promwad are focused on producing printed circuit boards capable of handling rapid signal transmission and minimising signal integity issues. Employ our expertise in multi-layer, mixed-signal, and high-speed board design services from the block diagrams to all necessary documentation and manufacturing support.

Besides high-speed designs, we obtain full-fledged capabilities for hardware simulation & analysis: pre-layout and post-layout signal integrity, power integrity, thermal analysis, and EMC/EMI. Our advanced tools and experienced engineers ensure the seamless design and optimisation of high-performance electronic systems.

Design Procedure

Each project comprise a diverse set of offerings and services, but the overall high-speed PCB manufacturing procedure consists of:

Block diagram

Block diagram

Design specification

Design specification

Library components review

Library components review

Schematic design

Schematic design

Schematic review FW engineer

Schematic review FW engineer

Components placement

Components placement

Layer stack calculation

Layer stack calculation

Pre-layout analysis

Pre-layout analysis

PCB routing

PCB routing

PCB layout review

PCB layout review

Post-layout analysis

Post-layout analysis

Design documentation development

Design documentation development

Result: We take responsibility for each stage of the PCB manufacturing process, as well including handling challenges like reduced engineering time or increased complexity. We make sure you get the best quality design on time and budget.

Our Experience

PCIe – 6; FMC cards – 12; PCIe104 – 3; PXIe – 1; SoM – 7; RF – 3; mini-PCIe – 2

PCIe, 10GbE, 100GbE; CameraLink, MIPI, HDMI, DP; DDR4, JESD204b

Featured Case Study

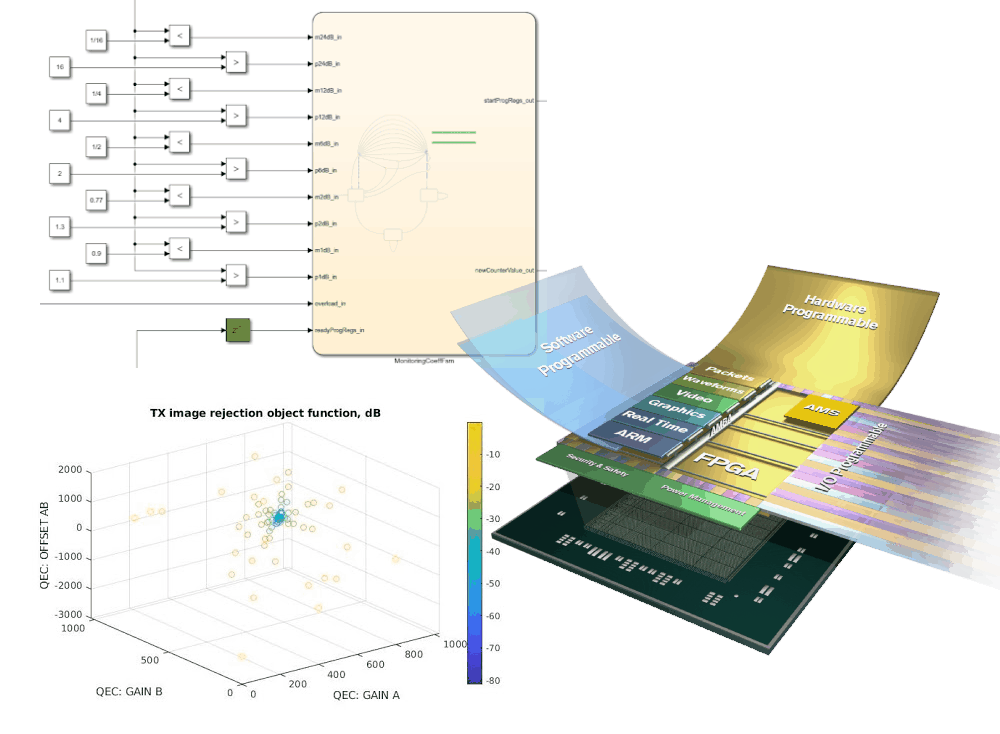

Satellite modem design

We designed the device in a compact 1U form factor by dividing it into digital and analog boards. Our engineers have developed a dedicated front end using high-speed ADC/DAC converters and modern high-frequency analog modulators/demodulators. We reached high-speed data exchange between server and device with the help of four 10G interfaces and the DPDK framework. To configure the device and measure the signal parameters, we developed a graphic application.

Hardware Simulation and Analysis

We deliver high-speed PCB manufacturing solutions along with combined signal integrity, power integrity, thermal analysis, and EMI/EMC.

Design Output Options

By request of our customers, we provide preferable for them design documentation options:

PCB Manufacturing

- Gerber and NC drill files

- ODB++ (if needed)

- IPC-D-356 file for electrical test

- Drill drawing PDF-file

Assembly Manufacturing

- BOM

- Stensil apertures for solder paste

- Component placement file

- Assembly diagram for top and bottom layers

- Shematic files

Our Hardware Development Projects

As a hardware development company, we have successfully completed numerous projects for a diverse range of industries, including telecommunications, automotive, and consumer electronics.

Do you need a quote for a high-speed PCB design project?

Please, drop us a line. We will contact you today or next business day. All submitted information will be kept confidential.