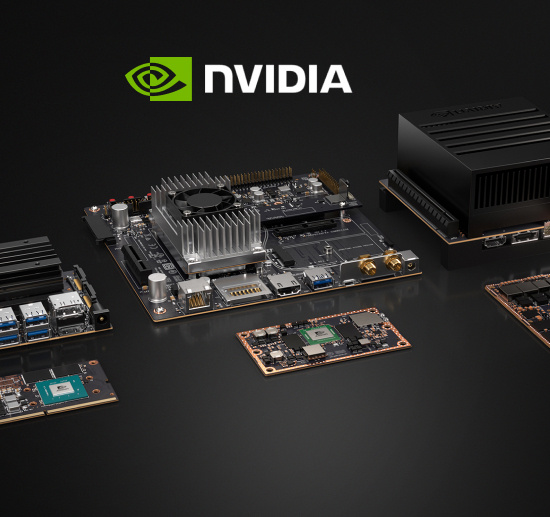

Custom Carrier Boards for NVIDIA Jetson + Holoscan-Ready Sensor Platforms

Turn NVIDIA modules – Jetson AGX/Thor/Xavier – into production-grade robotics and industrial devices with the exact I/O, high-speed connectivity, and software stack your product needs.

Promwad helps product teams move beyond dev kits and demos — to reliable, manufacturable Jetson-based platforms with predictable performance and a clear path to compliance and scale.

22+ years in embedded engineering

hardware + BSP + drivers+ apps

EMC, security, industrialconstraints

Why Promwad

We de-risk Jetson-based productization by owning the full chain: electronics → bring-up → BSP/drivers → performance tuning → manufacturing readiness.

What that means for your team: fewer integration surprises, fewer redesign cycles, and one accountable partner from schematic to software integration and production handoff.

High-speed design competence

Signal integrity / power integrity, EMC-aware layout decisions, clocking and timing strategy, power sequencing, and thermal constraints — planned from day one, not patched later.

Turnkey delivery across hardware and software

Custom carrier board + mechanical/thermal coordination + BSP/Yocto + device tree/kernel work + sensor drivers + Holoscan pipelines.

Manufacturing-minded engineering

DFM/DFT, component strategy, test points, production documentation, test-jigs concept, and smooth handoff to your EMS/manufacturing team.

Real product experience with NVIDIA compute modules

Not “dev kit adaptation,” but robust module integration into market-ready devices — with the interfaces, power design, and reliability your application requires.

EU-first compliance readiness

Design choices aligned with EMC/CE/FCC considerations, security-by-design practices, and industrial environment constraints (noise, vibration, temperature, uptime).

NVIDIA Jetson Modules We Employ

Jetson Nano

Jetson TX2

Jetson AGX Xavier, Xavier NX

Jetson AGX Orin, Orin NX, Orin Nano

Ready to productionize your Jetson platform?

Share your module (AGX/Xavier/Thor) and interfaces — we'll deliver a hardware + software architecture optimized for performance and manufacturing.

Our Tech Stack

NVIDIA ecosystem coverage

- Software foundation: JetPack/Linux, BSP & bring-up, Yocto, device tree, kernel work, camera/sensor drivers

- Acceleration & frameworks (as needed): CUDA, DeepStream, Isaac, Holoscan SDK

High-speed interfaces

- Expansion: PCIe Gen4/Gen5, USB 3.x

- Sensors & video: MIPI CSI-2

- Displays: DisplayPort / eDP / HDMI, LVDS

- Industrial I/O: CAN, RS-485, GNSS, Wi-Fi/BT

FPGA + sensor transport (for Holoscan scenarios)

- Tech vendors ecosystem: Lattice, Microchip

Standards & requirements readiness

Security & device lifecycle

Application Areas

Robotics

Industrial Edge Gateways & AI Boxes

Industrial HMI & Tablets

Smart surveillance

Industrial robotics

Predictive maintenance

Audio analytics

Body monitoring

Autonomous vehicles

Face recognition

Facial expression analysis

Key Transformation

From NVIDIA dev kit / reference designs → production-grade hardware and software

You already chose Jetson for performance. Now you need the parts that make it a product: correct I/O, robust power design, thermal stability, maintainable software, and predictable sensor pipelines.

What Promwad changes (before → after)

- Prototype wiring → robust board-level integration (SI/PI/EMC-aware)

- Ad-hoc drivers → maintainable BSP + reproducible builds (Yocto/CI practices)

- Uncertain sensor latency → tuned Holoscan pipeline with measurable throughput/latency targets

- Lab prototype → DFM/DFT + test strategy + production documentation

If you can share your module choice, interface matrix, and sensor set, we can propose an architecture and delivery plan.

Ivan Kuten, Managing Director and Technical Advisor at Promwad GmbH

Explore Our Case Studies

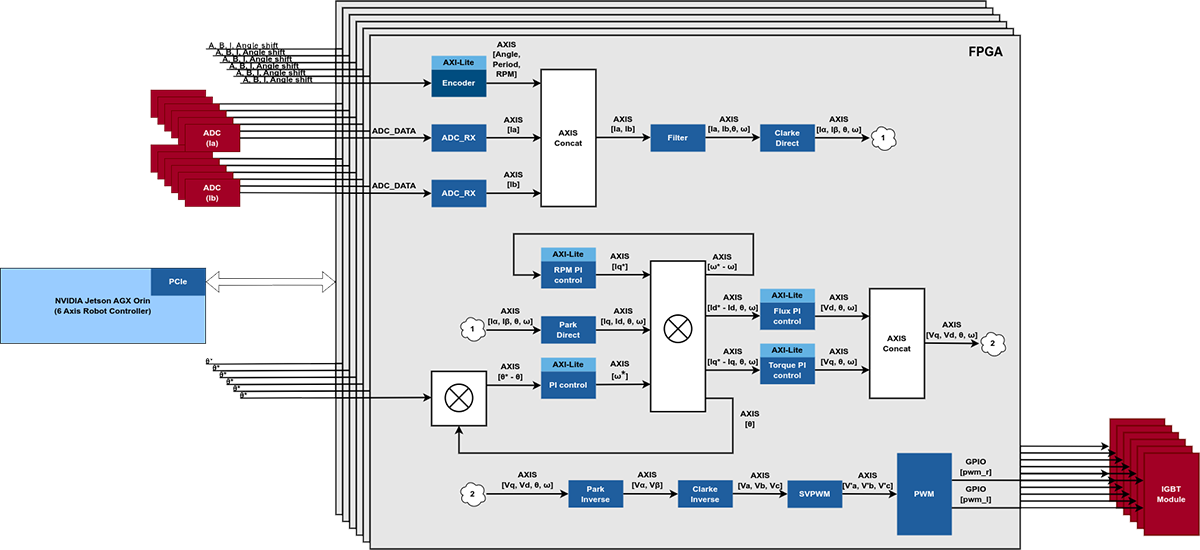

6-axis robot controller with the NVIDIA Jetson Orin and Xavier

IP cores: PCIe, 6 servo drive

The integration of servo drive IP cores into an FPGA is a robust solution for achieving optimal performance in robotics solutions. Using up to 6 servo drive IP cores per FPGA, we ensured high precision and control.

We resolved dynamic and spatial orientation challenges for 6-axis robots with the Jetson Orin and Xavier platforms that provided a new level of hardware solutions for robotics.

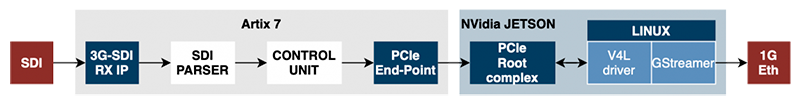

3G-SDI stream H.265 compression

The device compresses a 3G-SDI input stream with the H.265 encoder. A V4L2 driver adapts the PCIe data stream to be processed by GStreamer and HW codec. Linux controls the output bitrate by network throughput estimation (QoS). The PCIe links and delivers a low latency encoding chain.

How We Ensure Quality

Engineering process that de-risks delivery

Software quality & maintainability

Verification & test strategy

Manufacturing handoff deliverables

Trusted by Leading Tech Vendors

Promwad works inside the ecosystems of leading semiconductor and software vendors, combining their platforms with our engineering expertise to deliver production-ready devices, not reference designs.

NVIDIA is one of our key technology vendors: we build and productize solutions around the Jetson + Holoscan ecosystem for robotics, industrial AI, and high-performance edge systems.

This multi-vendor expertise lets us design heterogeneous, future-proof platforms — Jetson compute combined with FPGA bridging, industrial networking, high-speed sensor pipelines, and secure software stacks.

Ready to productize your Jetson platform — with the I/O, performance, and reliability your market expects?

FAQ

What is a Jetson carrier board and when do you need a custom one?

A carrier board adapts the Jetson module to your product’s power, I/O, and mechanical constraints. You typically need a custom board when dev kit interfaces, form factor, thermals, or reliability don’t match production requirements.

Can you start from our interface requirements and propose an architecture + BOM strategy?

Do you work with Jetson AGX / Xavier / Thor and industrial modules?

Yes — across relevant Jetson families and production/industrial contexts.

Can you deliver both hardware and software (BSP, drivers, application pipeline)?

Yes. We deliver an integrated stack: carrier board + bring-up + BSP/Yocto + drivers and, when needed, Holoscan pipelines.

How do you handle high-speed interfaces like 10G/MGBE/PCIe Gen4/Gen5 and MIPI CSI-2?

With disciplined architecture and layout governance: stack-up planning, impedance control, topology selection, validation strategy, and early EMC/SI/PI risk management.

Can you build an FPGA-based interface board and integrate it with Holoscan?

Yes — including deterministic sensor transport, timing strategy, and Holoscan pipeline integration.

Do you support rugged/industrial requirements?

Yes. We consider temperature ranges, vibration, noise immunity, and enclosure/IP targets as part of system-level design.

How do you approach security (secure boot, OTA) and IEC 62443 readiness?

We plan security and lifecycle early: secure boot options, update strategy, and industrial cybersecurity practices aligned with IEC 62443 expectations.

What deliverables do we receive and who owns the IP?

You receive full engineering deliverables for manufacturing and maintenance. IP ownership is defined contractually — typically, the client owns the project-specific IP.

Can you support manufacturing ramp-up and production troubleshooting?

Yes — test strategy, documentation, coordination with EMS, and support during ramp-up and early production.