Production

Testing

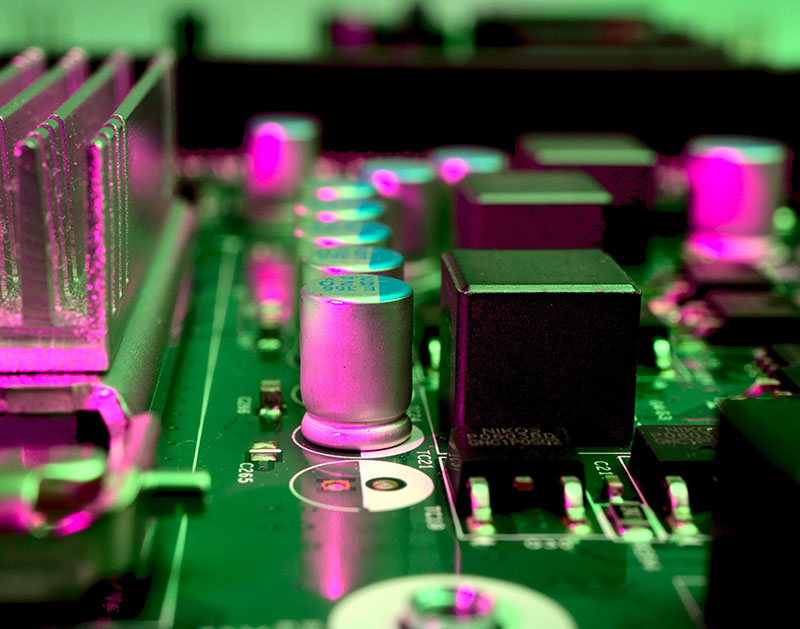

In-Circuit Testing & Electronics Quality Control

What We Do

Promwad experts manufacture and test electronics at our trusted production sites in Europe and Asia, covering any production volume, from individual samples within our prototype development services to large batches of PCBs.

- Design and manufacture of testing benches for installation of firmware and testing using ICT/JTAG services

- Development of testing systems and quality control criteria for product acceptance

- Automated or manual testing processes

Types of Testing in Production

In-circuit testing

ICT / FICT helps check the components and their connections on the printed circuit board through the use of contact probes, including a stationary field ("bed of nails") or "flying" probes and matrices. ICT is used to analyse electrical parameters of individual sections or the entire circuit in PCB manufacturing. This technique is based on preprocessing preparation, manufacturing of tooling, and application of advanced equipment.

Peripheral and boundary scan

Promwad is an authorised distributor of JTAG Technologies and developer of test applications for boundary-scan for JTAG systems. This scan can be used for chips with IEEE 1149 support.

Functional testing

Our Case Studies in Production Support

Do you need a quote for your electronics manufacture and functional testing?

Drop us a line about your project! We will contact you today or the next business day. All submitted information will be kept confidential.