3D Printed Electronics: From Prototyping to Mass Production

Not long ago, the idea of “printing” electronics seemed more like science fiction than reality. We were used to thinking of electronics as rigid, carefully etched boards covered with components soldered in place. The notion that you could print conductive traces, resistors, antennas, or even simple sensors directly onto flexible materials sounded almost too futuristic. But today, 3D printed electronics are no longer limited to experimental labs. They are steadily moving from rapid prototyping toward real industrial-scale production, opening a new chapter for the electronics industry.

The journey from idea to mass production has not been easy. It has required breakthroughs in materials, printing processes, and hybrid manufacturing. It has also required industry adoption, because no technology becomes mainstream unless companies find a way to turn it into real products. Right now, we are at a point where 3D printed electronics are no longer a curiosity but a technology with a clear path to scaling.

Why 3D printed electronics are becoming important

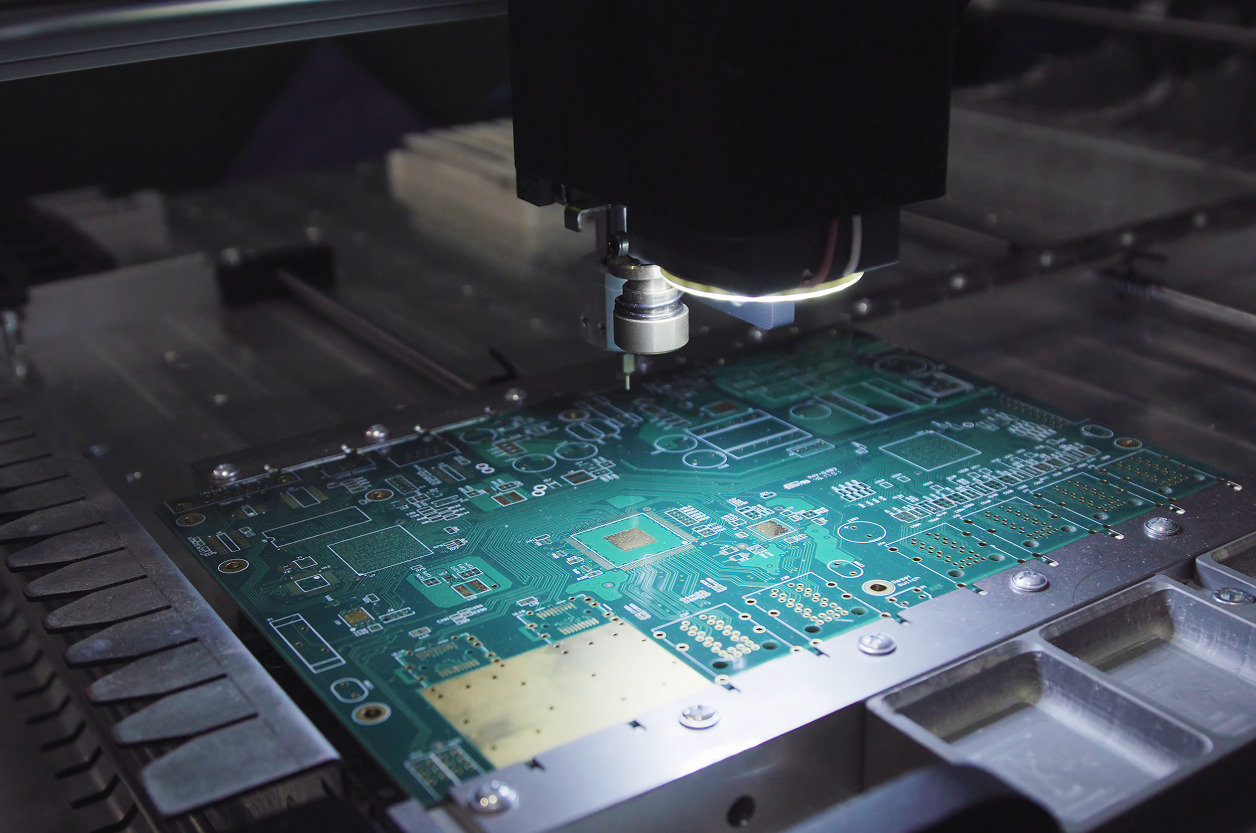

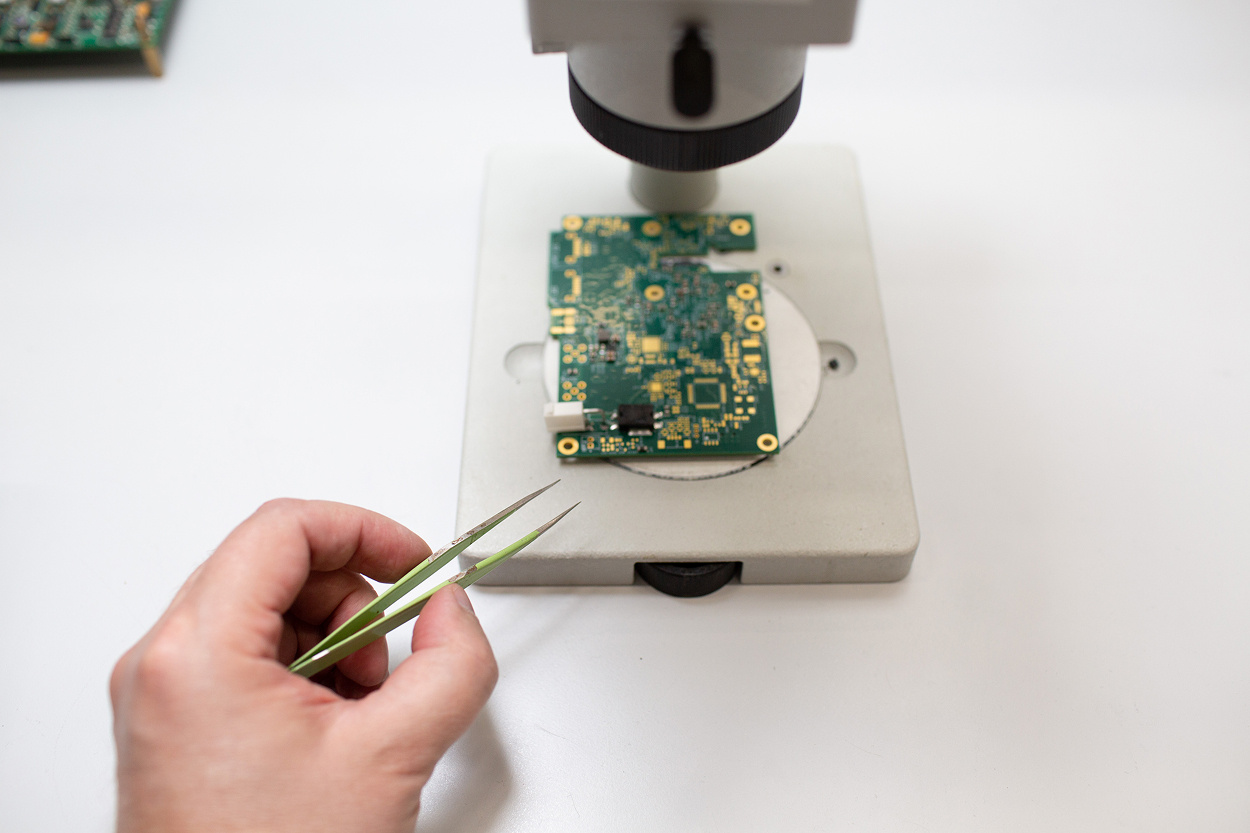

Traditional electronics manufacturing has worked well for decades, but it is also full of bottlenecks. Creating a printed circuit board (PCB) requires multiple steps: layering, etching, drilling, plating, soldering. The process is rigid, time-consuming, and creates significant waste. Prototyping is even slower, since every design change often requires a completely new PCB run.

3D printed electronics disrupt that model. Using conductive inks, insulating polymers, and additive processes, it is now possible to print circuits directly onto flat or curved surfaces. For engineers, that means an idea can move from CAD software to a working circuit in hours rather than weeks. For companies, it reduces costs, speeds up iteration cycles, and creates opportunities for new kinds of devices.

Take wearables, for example. Traditional PCBs don’t fit well with the curved shapes of the human body. Flexible, printed circuits, however, can be integrated into fabrics or thin films without adding bulk. Another example is automotive dashboards. Instead of building separate rigid boards and connectors, manufacturers could print circuits directly onto interior surfaces, reducing assembly complexity.

The importance is not only in cost savings. It is also in design freedom. Engineers are no longer bound by flat boards. They can design electronics that conform to whatever shape best fits the application. That shift has the potential to redefine how we think about integrating electronics into products.

The breakthroughs that make mass production possible

For years, printed electronics were stuck in the prototype stage. A lab could make something cool, but scaling it to thousands or millions of units wasn’t realistic. That is starting to change because of a series of technical breakthroughs.

First, conductive inks have improved dramatically. Early versions either didn’t conduct electricity well or degraded quickly. Today, silver nanoparticle inks, carbon nanotube inks, and even graphene-based solutions are available with reliable conductivity. These inks can withstand mechanical stress and environmental exposure, making them more suitable for real products.

Second, hybrid manufacturing systems have appeared. Purely printed circuits are limited, because most electronics still need conventional chips, microcontrollers, and sensors. Modern 3D printers can integrate additive processes with pick-and-place machines, embedding traditional chips into printed structures. This hybrid approach combines the best of both worlds — the flexibility of printing with the reliability of existing components.

Third, roll-to-roll printing has scaled up. Instead of printing one board at a time, companies can now print continuous sheets of flexible electronics, similar to how newspapers are printed. This roll-to-roll process is critical for reducing costs and making mass adoption viable.

Finally, there is a growing ecosystem of applications. When companies in healthcare, automotive, logistics, and consumer electronics start adopting a technology, suppliers and manufacturers have an incentive to refine and scale it. That market pull is now evident with printed electronics.

The challenges that still need solving

Despite progress, 3D printed electronics are not a replacement for traditional PCBs across the board. There are still significant limitations.

Performance is one of them. Printed electronics are not yet capable of handling the same high frequencies, high voltages, or high power that rigid PCBs can manage. That means they are well-suited for low-power sensors, wearables, and flexible devices, but not yet for server motherboards or aerospace control systems.

Reliability is another concern. Electronics are expected to last years, even decades, in some industries. Printed traces and inks still need more testing to prove they can endure extreme heat, cold, humidity, or mechanical stress. Automotive and aerospace sectors, in particular, demand rigorous standards before adoption.

Standardization is also an obstacle. Every printer, every ink, and every curing process can lead to slight variations in performance. Until the industry agrees on common standards, it will be difficult to build global supply chains at the scale we see with silicon-based electronics.

In other words, 3D printed electronics are not a silver bullet. They are a complementary technology, and in the short term, they will live alongside traditional PCBs rather than replacing them.

Real-world applications that show the future

Even with limitations, there are already impressive examples of 3D printed electronics making an impact in real products:

- Healthcare and biotech: Printed biosensors are being integrated into skin patches that can measure glucose levels, hydration, or heart rate. Smart bandages can monitor wound healing without bulky devices. Because they are lightweight and disposable, they reduce costs and improve patient comfort.

- Automotive: Flexible circuits are being printed into curved interior panels, seat sensors, and lighting controls. This reduces the number of parts, simplifies assembly, and enables creative designs that weren’t possible with rigid boards.

- Consumer electronics: Wearables such as fitness trackers and smart clothing are using printed electronics to stay lightweight and comfortable. Instead of embedding rigid chips, conductive inks can follow the natural shape of the body.

- Logistics and retail: Low-cost printed RFID tags and antennas are making it easier to track goods at scale. Because they are cheaper and faster to produce, companies can deploy them more widely than traditional tags.

- Energy and IoT: Printed solar cells and antennas are being tested as low-power energy sources for sensors. This could lead to a new generation of self-sustaining IoT devices.

Each of these applications shows that 3D printed electronics are not just an experimental idea — they are already being deployed where their unique advantages outweigh the limitations.

What the next decade could bring

If current trends continue, the next decade could see 3D printed electronics become a standard tool in the electronics manufacturing toolkit. They won’t replace every PCB, but they will dominate areas where flexibility, speed, and customization matter most.

One possibility is electronics integrated seamlessly into fabrics. Imagine clothing that can monitor health, adjust temperature, or connect to devices without bulky sensors. Another possibility is smart surfaces — furniture, car interiors, or walls that can host embedded sensors, lighting, or connectivity without visible wiring.

There is also potential for integration with other advanced technologies. For example, combining printed electronics with neuromorphic chips, photonic circuits, or quantum components could create entirely new classes of devices. The flexibility of printing could make it easier to experiment with unconventional designs.

Perhaps the biggest change will be cultural. Engineers will start designing electronics without thinking about the constraints of flat, rectangular PCBs. Instead, they will have the freedom to shape electronics around human needs and product design, not the other way around. That shift is subtle but revolutionary.

The bottom line

3D printed electronics are moving quickly from the lab to the factory. Thanks to improvements in materials, hybrid systems, and scalable production methods, they are no longer just for rapid prototyping. They are becoming a real option for manufacturing at scale.

Challenges remain, especially around performance, reliability, and standardization. But the momentum is undeniable. Early adopters in healthcare, automotive, consumer electronics, and logistics are proving the value of printed electronics in practice.

The real excitement lies in what comes next. Over the next decade, as the technology matures, we could see a wave of products that integrate electronics in ways that were impossible with traditional methods. From flexible wearables to smart surfaces and self-powered IoT devices, the potential is enormous.

The journey from prototyping to mass production is well underway, and those who embrace it early may set the pace for the next generation of electronics manufacturing.

Our Case Studies