Universal Embedded HMI Platform for Agricultural and Construction Machinery

Project in Nutshell: We designed a versatile HMI platform for controlling agricultural and construction outboard machinery that integrates seamlessly with existing off-the-shelf solutions and can be customised to meet specific client requirements. It accelerates the development process, enabling faster deployment and reduced time to market.

Challenge

Modern tractors and construction machines are complex robotic systems, often autonomously controlled. Human's role has shifted to that of an operator controlling these machines.

Despite advances in automotive technology, the agricultural and construction industry often uses solutions with limited functionality and outdated graphics to display the control processes of connected machines. This is due to the small production volumes of specialised machinery — from hundreds to a few thousand units per year. Individual HMI screen development for each type of machine, e.g. seeders or sprayers, is too expensive.

Our clients who develop engineering solutions for agriculture and construction are well aware of the problem described. That is why Promwad's engineering team has set a goal to provide these niches with a universal solution for fast HMI development based on a ready-made platform.

Solution

We have created a universal HMI platform, which already implements a basic set of functions for easy and quick integration with existing solutions and customisation to the requirements of a specific application.

Software & Hardware Design

The HMI platform is based on the NXP i.MX 8M Plus processor, which supports high-quality graphics and connectivity for up to four 4K displays. This low-cost processor can combine all the necessary information into one comprehensive and easy-to-use interface, displaying clear and detailed visual data. Multi-display HMI architecture supports a single, coherent operator interface across several screens while keeping graphics performance and connectivity within one embedded platform.

The i.MX 8M Plus processor from NXP

The platform is built with C++ and Qt for HMI development, allowing user interface customisation and integration with different operating systems.

The C++ language is ideal for HMI development due to its high performance and efficiency, which is important for real-time systems. It provides robust and flexible programming, allowing you to create complex and responsive interfaces. In addition, C++ HMI development in conjunction with Qt frameworks allows you to create visually appealing and user-friendly solutions.

The platform is designed with future integration capabilities in mind. Further, we will add ISOBUS compatibility for seamless connection between different technologies.

Also, the integration with the SDV platform will allow the system to operate as a central computer that does not require an internet connection.

Platform Features

The platform is designed to meet the needs of reliability, security and convenience. Through the technologies used, it offers extensive customisation options, as well as:

- improved graphics and support for multiple displays;

- various camera outputs, including 360 cameras;

- precision farming support for efficient and accurate farming operations.

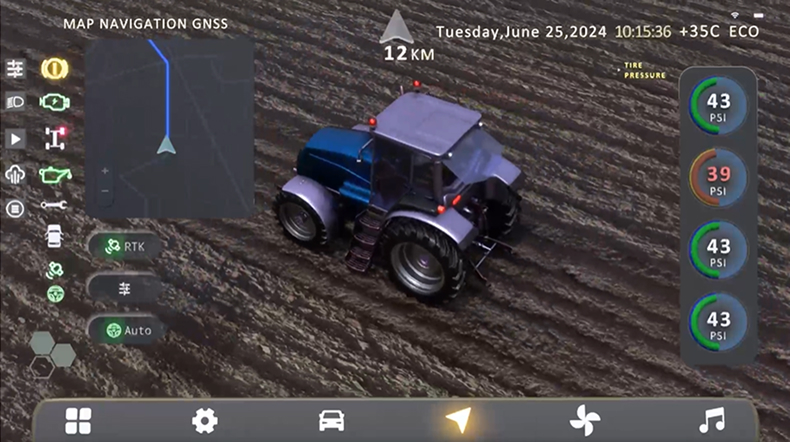

The platform interfaces can be customised to the user's needs and display the following information in real-time:

- systems error detection;

- status of the engine, transmission, oil system, body terminals;

- vehicle maintenance needs;

- tyre pressure;

- quality of satellite communication, GPS, map and position in space;

- automatic driving, ADAS.

An example of information that can be displayed in the platform interfaces: system status, tyre pressure, map, and error messages

Switching on transparency mode allows you to look inside covered components and see all elements under transparent layers of the system, even if they are hidden by the casing or other parts, such as the chassis or engine.

Highlighting hidden system elements when transparency is enabled

The dashboard interface is also customisable and can display dozens of indicators, for example:

- attention indicator and/or parking brake;

- fuel consumption;

- cooling system indicator;

- multimedia and connectivity (radio, BLE, WIFI, GSM);

- tachometer;

- speedometer.

Dashboard to display all the necessary indicators: from the comfort function in the cabin to the pressure in the hydraulics

Business Value

The designed versatile HMI platform provides intuitive settings and real-time monitoring and control of agricultural and construction outboard machinery. Utilising such a platform provides the following business benefits:

- Reduced time to market. The adaptability of the platform speeds up the design process and enables faster equipment deployment.

- Cost-effective customisation. Universal design reduces the need for multiple screens and simplifies quality control.

- Scalability. Thanks to Qt, the HMI platform can be easily scaled and integrated with different operating systems.

More of What We Do for Agricultural Industry

- Agricultural Machinery: our expertise in software and hardware design with case studies on embedded solutions for agricultural equipment.

- ISOBUS Solutions: our services for the development and integration of ISOBUS stacks for data exchange between agricultural equipment from different manufacturers.

- ISO 25119: how we implement the software development standard for functional safety of agricultural machinery.