Flexible and Stretchable Electronics: What’s Next Beyond Wearables

When people first heard about flexible electronics, most thought of bendable screens or fitness trackers. That was the first wave, and it proved that electronics don’t have to live inside rigid boxes. But the story didn’t stop at wearables. Flexible and stretchable electronics are quietly moving into medicine, robotics, cars, aerospace, and even energy. This isn’t about a gimmick like a phone you can fold; it’s about rethinking what an electronic system can be when it’s no longer locked into stiff silicon boards.

How do flexible and stretchable electronics differ from traditional designs?

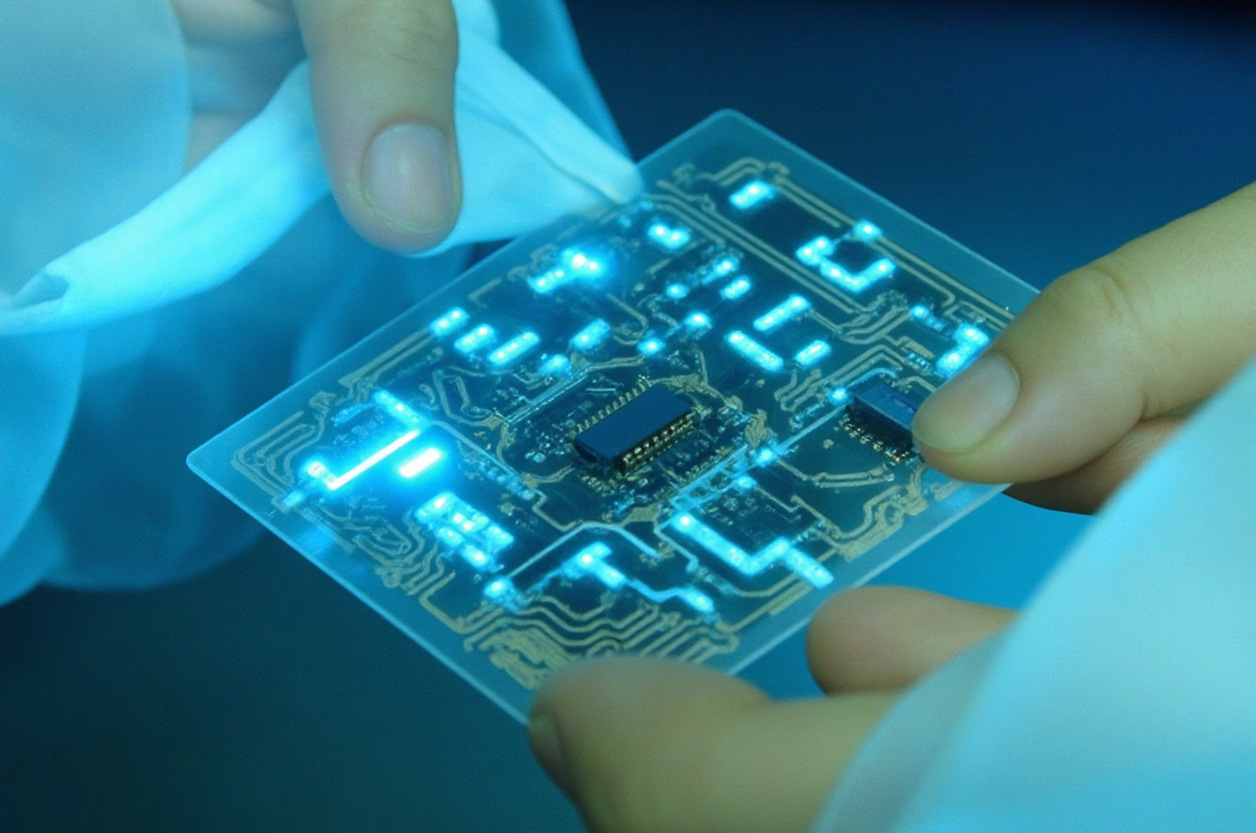

Rigid electronics are reliable but unforgiving. A printed circuit board will do its job perfectly, as long as you don’t try to bend it. Flexible and stretchable electronics flip that logic. Built on thin polymers, soft films, or conductive inks, these systems can bend, twist, and even stretch like elastic without breaking.

The distinction matters. Flexible means you can roll a display or wrap a sensor around a curved surface. Stretchable goes further: the circuit can expand and contract repeatedly, like a rubber band, and still function. That makes it perfect for applications that need continuous movement, whether it’s a skin patch that follows your arm or a robotic arm that grips irregular shapes.

This shift is not just a materials trick. It changes how engineers design systems. Instead of cramming chips into rigid shells, they can now embed them into fabrics, medical implants, or curved surfaces. In practice, this means electronics become part of the environment rather than something you attach to it.

Where are flexible and stretchable electronics going beyond wearables?

Healthcare is one of the first industries embracing this technology. Imagine a medical patch as thin as a bandage that tracks your hydration, heart rate, or glucose levels continuously. No wires, no gels, no hospital machines — just a breathable patch that feels natural on the skin. Clinical trials are already exploring these kinds of sensors for chronic disease management.

Implantable devices are another frontier. Traditional implants, like pacemaker leads, often face mechanical stress because the human body moves constantly. Stretchable electronics reduce that mismatch. They can bend and flex with tissue, lowering risks of failure and making implants last longer.

Robotics is also being reshaped. Soft robots are moving from science labs into real-world use. They’re built to squeeze into disaster zones, assist surgeons, or handle fragile food items. What makes them viable are circuits and sensors that can bend and stretch with the robot’s body. A rigid PCB doesn’t work in a tentacle-like robot, but stretchable electronics make it possible.

The automotive and aerospace sectors are starting to see flexible displays and sensors as a way to rethink design. Picture a dashboard where information appears seamlessly across a curved surface, or seats that monitor a driver’s posture and fatigue in real time. Stretchable pressure sensors in steering wheels could even detect grip strength and trigger alerts if the driver is drowsy.

Energy is another unexpected area. Thin, flexible solar cells could be integrated into surfaces we never thought of — jackets, tents, or even car exteriors. Stretchable batteries, still in development, aim to provide power for tiny IoT devices that can’t accommodate rigid packs.

What breakthroughs are making this possible?

The progress comes from a mix of materials science and new manufacturing methods. Conductive polymers, graphene, and carbon nanotubes are leading candidates because they conduct electricity while staying flexible. Instead of snapping like a copper trace, these materials stretch and recover.

Hybrid electronics are also key. In many designs, you still need the computational power of silicon chips. Engineers are now embedding those chips into flexible substrates with special interconnects. The result is a compromise: the brain of the system remains traditional, but the body adapts.

Printing is another revolution. Instead of etching rigid boards, manufacturers are starting to print circuits using conductive inks on flexible rolls of film. Roll-to-roll printing, similar to newspaper production, could bring costs down and open the door to mass production.

Encapsulation is the often-overlooked piece. Flexible electronics only matter if they survive in the real world. Protective coatings now allow circuits to resist sweat, humidity, and mechanical wear. Without this, medical patches or automotive sensors wouldn’t be viable outside the lab.

How is the market shaping up?

The numbers show strong momentum. In 2023, the stretchable electronics market was valued at just over 400 million dollars. Forecasts suggest it could reach around 2 billion dollars by 2030, with a compound annual growth rate of more than 25 percent. This isn’t speculative hype — it’s driven by healthcare demand, robotics startups, and big automotive players looking for the next edge in design.

Governments and industry alliances are also playing a role. Programs in the US, Europe, and Asia fund research into flexible hybrid electronics, linking universities with companies to accelerate commercialization. It’s not a race any one company can win alone. Collaboration is the only way to move from niche prototypes to reliable mass-market products.

What makes this field strategic is not that it replaces rigid electronics, but that it expands them. Just as miniaturization turned computers into smartphones, flexibility is turning electronics into materials that can live anywhere — on skin, in clothing, inside vehicles, or even within living tissue.

The vision is pervasive computing: electronics so integrated into daily life that you stop noticing them as devices. They simply become part of the fabric of our environment, literally and figuratively.

Our Case Studies