Self-Healing Hardware: Runtime Reconfiguration Against Aging and Faults

As embedded systems grow more complex and pervasive—from industrial control to automotive ECUs and satellites—they face a quiet but inevitable enemy: hardware aging. Every microchip slowly degrades through thermal stress, voltage fluctuations, radiation exposure, and constant operation. Over time, this leads to faults, slower performance, and even catastrophic system failures.

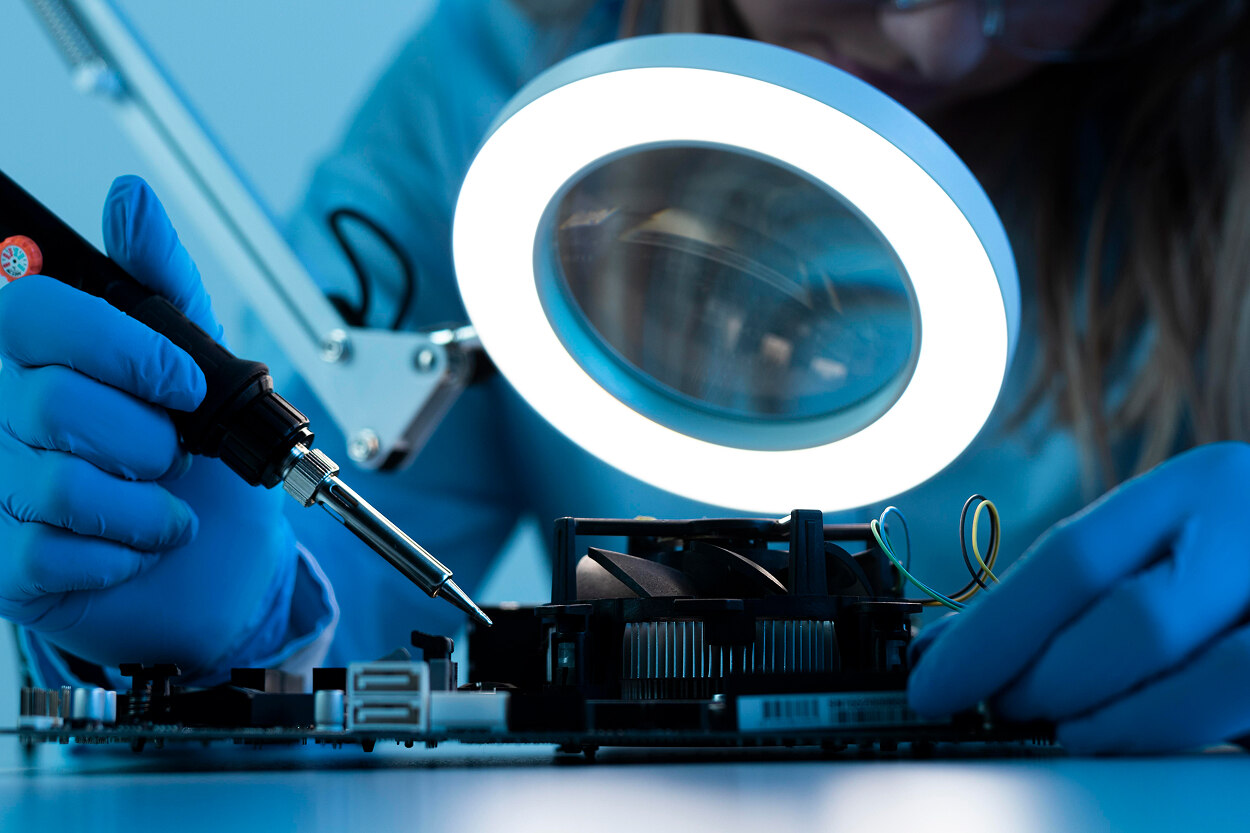

In mission-critical or long-lifecycle applications, maintenance or replacement is often costly or impossible. To address this, engineers are turning to a transformative concept: self-healing hardware — systems that monitor their own health, detect anomalies, and autonomously reconfigure themselves to maintain functionality.

In 2025, self-healing designs are no longer confined to academic labs. They’re emerging in aerospace, automotive, telecom, and industrial systems, driven by advances in runtime reconfiguration, embedded AI diagnostics, and adaptive FPGA architectures.

The problem: aging, wear, and unpredictable faults

Electronic components degrade naturally over time due to mechanisms like:

- Electromigration: movement of metal atoms under high current density, degrading interconnects.

- Bias temperature instability (BTI): transistor threshold voltage drift, reducing switching speed.

- Hot-carrier injection (HCI): charge trapping that weakens transistors.

- Single-event upsets (SEU): bit flips from cosmic radiation or EMI.

In traditional systems, engineers overdesign hardware to tolerate these effects, using redundancy, conservative voltage margins, and environmental controls. But this approach is inefficient, power-hungry, and unsustainable for edge and embedded devices operating for decades.

What is self-healing hardware?

Self-healing hardware refers to systems capable of detecting faults and dynamically adapting to preserve function — without external intervention. It combines:

- Sensing: monitoring electrical, thermal, and performance indicators.

- Diagnosis: identifying when and where degradation or fault occurs.

- Reconfiguration: rerouting signals or reprogramming components to avoid faulty regions.

This can be implemented at different abstraction levels — from circuit and architecture to system software. The goal is to shift from fail-and-replace to predict-and-recover.

The enabler: runtime reconfiguration

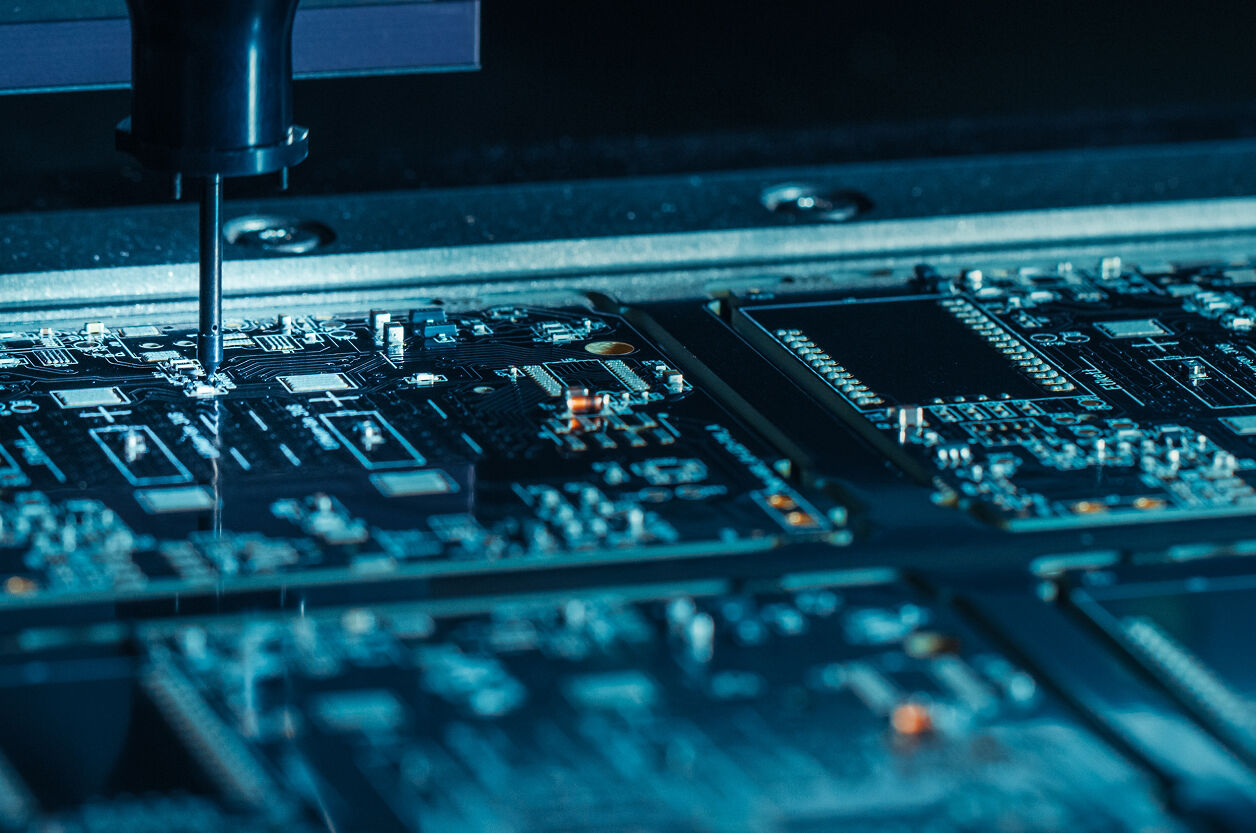

The most effective approach to hardware self-healing is runtime reconfiguration, particularly in FPGA-based designs.

Unlike ASICs, FPGAs can reprogram parts of their logic on the fly. This allows systems to:

- Bypass faulty logic blocks or interconnects.

- Reroute functions through healthy regions.

- Adjust clock or voltage parameters to counteract performance loss.

For instance, if a lookup table (LUT) or routing switch in an FPGA fabric shows errors, the configuration bitstream can be dynamically updated to replace that area with a redundant region — all while keeping the device operational.

Modern devices like AMD/Xilinx UltraScale+ or Intel Agilex FPGAs already support partial reconfiguration, enabling local hardware adaptation during operation.

AI meets self-healing hardware

AI and machine learning are transforming fault tolerance from reactive to predictive. Embedded models analyze sensor data — voltage droop, current spikes, or timing errors — to forecast failures before they cause damage.

For example:

- Neural anomaly detectors can identify early signs of transistor aging from power signatures.

- Reinforcement learning agents can optimize reconfiguration strategies based on performance vs. energy trade-offs.

- Bayesian networks can estimate system health probabilities across redundant paths and modules.

This shift creates an intelligent control loop: Monitor → Predict → Reconfigure → Validate.

In essence, the hardware begins to exhibit behavior similar to biological systems — detecting “injuries” and regenerating pathways to stay functional.

Real-world examples of self-healing designs

- Aerospace systems: Satellites use self-healing FPGA platforms for radiation-induced fault recovery. When a configuration bit flips due to cosmic rays, the system reloads the affected section autonomously.

- Automotive ECUs: Safety controllers detect drift in analog sensors and recalibrate input mappings dynamically.

- Industrial controllers: Predictive thermal monitoring detects solder joint fatigue or PCB trace degradation, triggering workload redistribution to cooler regions.

- Telecom infrastructure: 5G edge routers perform in-situ diagnostics and partial reprogramming to maintain uptime across multi-tenant networks.

In each case, self-healing mechanisms extend the system’s operational life, reduce maintenance intervals, and minimize downtime.

Techniques enabling runtime resilience

1. Redundancy-based healing

Classic approach where spare logic elements or paths replace failed ones. Now implemented dynamically with on-chip redundancy maps managed by control logic.

2. Partial reconfiguration

Selective reprogramming of faulty hardware regions without rebooting. Modern FPGA tools (Vivado, Quartus) support this with millisecond latency.

3. Approximate computing

When full precision isn’t required (e.g., image recognition), systems can bypass faulty units and use degraded but functional alternatives.

4. Adaptive body biasing and DVFS

Adjusting transistor thresholds and voltage/frequency dynamically compensates for aging-induced performance loss.

5. Error detection and correction (EDAC)

On-chip ECC (error-correcting code) and parity schemes detect bit flips, while reconfiguration corrects persistent errors beyond ECC scope.

These techniques combine into layered defense — from hardware-level mitigation to system-level adaptation.

Design challenges

Building self-healing systems introduces new engineering complexities:

- Monitoring overhead: continuous sensing consumes power and silicon area.

- False positives: overly sensitive fault detection may trigger unnecessary reconfigurations.

- Latency: reconfiguration must be fast enough not to interrupt real-time operation.

- Verification difficulty: dynamic logic paths complicate validation and certification (especially in automotive or aerospace).

- Security implications: reconfiguration mechanisms themselves must be protected from tampering.

To manage these risks, engineers are incorporating secure boot, authenticated bitstreams, and hardware attestation into reconfigurable platforms.

The link with predictive maintenance and Industry 4.0

Self-healing hardware aligns with the broader shift toward Industry 4.0 and cyber-physical resilience. In connected factories or energy systems, edge devices equipped with runtime diagnostics can:

- Report their health status upstream.

- Share insights with digital twins.

- Receive optimized reconfiguration profiles from cloud AI systems.

This creates a feedback loop where each device contributes to collective system reliability — a kind of “industrial immune system.”

For instance, a power inverter detecting degradation in its MOSFET drivers can reassign control loops to redundant channels, notify the supervisory controller, and log the event for analytics — all autonomously.

The next frontier: materials and circuit-level regeneration

Research is pushing beyond logic-level reconfiguration into physical self-repair:

- Self-healing polymers and conductive materials that restore electrical connectivity after cracks.

- Memristive circuits that “rewire” themselves via adaptive resistance changes.

- 3D-IC redundancy enabling layer-level failover in advanced chiplets.

While commercial deployment is still years away, these materials could complement runtime reconfiguration to enable true self-repairing electronics that evolve with use.

Outlook: toward lifelong electronics

By 2030, self-healing capabilities are expected to become standard in long-lifecycle systems — from aerospace and automotive to renewable energy and industrial automation.

The convergence of FPGA adaptability, embedded AI diagnostics, and secure runtime control will enable devices to maintain reliability far beyond their expected lifespans.

Instead of planning for failure, engineers will design systems that plan for recovery — reconfiguring, recalibrating, and rejuvenating themselves as conditions change.

This shift redefines reliability not as a static property, but as a living process — the foundation of sustainable, resilient electronics.

AI Overview: Self-Healing Hardware

Self-Healing Hardware — Overview (2025)

Self-healing hardware brings biological resilience to electronics, enabling systems to detect faults, predict aging, and reconfigure themselves in real time. Using runtime reconfiguration, AI diagnostics, and adaptive FPGA fabrics, devices can recover from degradation without downtime.

- Key Applications: aerospace electronics, automotive ECUs, industrial control, telecom edge devices, energy inverters.

- Benefits: extended lifespan, reduced maintenance, improved safety, operational continuity.

- Challenges: complexity, power overhead, verification, and security of reconfiguration mechanisms.

- Outlook: by 2030, self-healing architectures will underpin long-lifecycle electronics, merging predictive maintenance with autonomous repair for mission-critical systems.

- Related Terms: runtime reconfiguration, FPGA resilience, fault tolerance, aging compensation, predictive maintenance, adaptive circuits.

Our Case Studies