Stepper Motor Software: Complete Guide to Programming and Control Systems

Precision motion control drives everything from 3D printers creating intricate prototypes to CNC machines manufacturing critical components. At the heart of these systems lies stepper motor software—the digital brain that transforms electrical pulses into exact mechanical movements. Whether you’re building a robotic arm or designing an automated assembly line, understanding how to choose and implement the right software can make the difference between flawless operation and frustrating failures.

The stepper motor market, valued at approximately $2.1 billion according to industry reports, continues expanding as automation becomes essential across manufacturing, medical devices, and consumer electronics. This growth creates increasing demand for software solutions that can achieve precise control while remaining accessible to both seasoned engineers and newcomers to motion control.

In this comprehensive guide, we’ll explore everything from Arduino libraries that get hobbyists started to commercial software suites powering industrial systems. You’ll discover how to select the right platform for your project, implement effective programming techniques, and troubleshoot common issues that can derail your automation goals.

What is Stepper Motor Software?

Stepper motor software encompasses the digital tools and programming frameworks that control how stepper motors move, stop, and coordinate with other system components. Unlike traditional motors that spin continuously, stepper motors advance in discrete steps, making software critical for generating the precise pulse sequences that drive these incremental movements.

Core Functions and Capabilities

Modern stepper motor software handles several essential functions that determine system performance. Position control allows you to specify exact movement distances in step increments, ensuring your automated system reaches precise locations every time. Speed regulation manages how fast the motor moves by controlling the frequency of step pulses, while acceleration and deceleration profiles create smooth motion that prevents mechanical stress and missed steps.

The software also integrates feedback from sensors or encoders to verify movement accuracy. This becomes crucial in applications where precision directly impacts quality, such as medical device positioning or semiconductor manufacturing equipment.

Software Architecture Types

Stepper motor software operates at different levels within your control system. Firmware runs directly on microcontrollers or driver integrated circuits, managing the low-level timing and electrical signals that energize motor windings. This embedded code handles the critical real-time operations that ensure each pulse arrives at exactly the right moment.

Driver software serves as the communication bridge between your main application and the motor controller hardware. Whether running on a PC or embedded system, these drivers translate high-level commands into the specific protocols your motor controller understands. Libraries like Arduino’s AccelStepper provide pre-written functions that handle common tasks, allowing you to focus on your application logic rather than pulse timing calculations.

Control applications offer user interfaces for direct motor manipulation and configuration. These might be graphical programs for setting up complex motion sequences or command-line utilities for automated scripting and batch operations.

Hardware Integration Requirements

Effective stepper motor software must seamlessly interface with your chosen hardware platform. Controllers like the Pololu Tic T825 connect via USB, TTL serial, or I²C protocols, requiring software that can establish these communication channels and manage data exchange reliably. USB interfaces often appear as a virtual COM port on a PC, simplifying data communication and device interfacing.

The software needs to send configuration parameters, motion commands, and status queries while processing responses that indicate current position, error conditions, or completion status. This bidirectional communication ensures your system can adapt to changing conditions and recover from unexpected situations.

Popular Stepper Motor Software Platforms

The landscape of stepper motor software spans from beginner-friendly Arduino libraries to sophisticated commercial solutions designed for industrial applications. Each platform offers distinct advantages depending on your project requirements, technical expertise, and budget constraints.

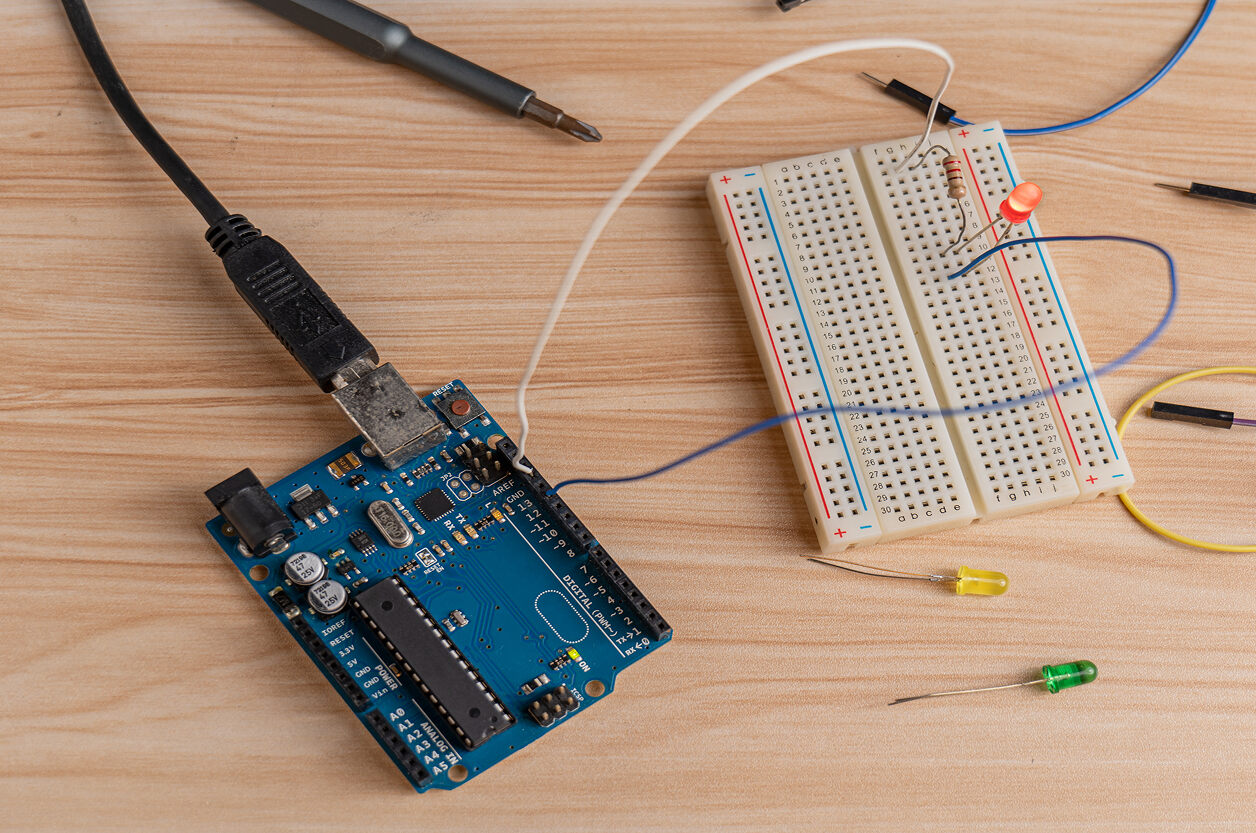

Arduino Libraries and Programming

Arduino dominates the hobbyist and prototyping space with its accessible programming environment and extensive library ecosystem. The platform’s popularity stems from its ability to get stepper motors moving with just a few lines of code, making it ideal for learning motion control principles or rapidly prototyping new concepts.

AccelStepper Library Features

The AccelStepper library stands out as the most comprehensive free software solution for Arduino-based stepper motor control. This library handles smooth acceleration and deceleration automatically, preventing the jerky movements that can damage mechanical systems or cause missed steps during rapid direction changes.

AccelStepper supports multiple motor interfaces, from simple step/direction signals to complex multi-phase configurations. The library can coordinate multiple motors simultaneously, enabling applications like 3D printers where several axes must move in perfect synchronization to create accurate parts.

Here’s a basic example of AccelStepper implementation:

Installing AccelStepper through the Arduino IDE Library Manager streamlines dependency management and ensures you receive updates automatically. The process involves opening the IDE, navigating to Tools > Manage Libraries, searching for “AccelStepper,” and clicking the install button.

Once installed, the library provides example sketches that demonstrate common usage patterns. These examples serve as templates you can modify for your specific motor controller and application requirements.

Communication Interface Programming

Arduino-based systems often need to communicate with external devices or user interfaces. Serial communication allows your Arduino to receive commands from a PC or send status information for monitoring. I²C implementation enables daisy-chaining multiple motor controllers on a single bus, simplifying wiring in complex systems.

The following example shows how to control a stepper motor via serial commands:

Commercial Software Solutions

Professional applications often require more robust software platforms that offer advanced diagnostics, comprehensive documentation, and vendor support. These commercial solutions typically provide better reliability and more sophisticated features than open-source alternatives.

Pololu Tic Software Suite

Pololu’s Tic stepper motor controllers include a complete software ecosystem designed for both standalone operation and PC integration. The ticcmd command-line utility enables scripting and automation, allowing you to create batch files that execute complex motion sequences or integrate stepper control into larger automation systems.

The Tic Control Center (ticgui) provides a graphical interface for real-time motor control and configuration. This Windows-compatible application simplifies initial setup and troubleshooting by offering visual feedback on motor status, current settings, and error conditions.

Installation requires downloading the appropriate Windows drivers and software package from Pololu’s website. The installation process includes USB drivers that enable your PC to recognize and communicate with Tic controllers automatically.

Advanced Controller Features

Commercial controllers like the Pololu Tic series offer features that extend beyond basic motor control. These devices can store preset command strings and motion profiles in internal memory, enabling standalone operation without continuous PC connection. Digital and analog triggers can initiate stored sequences automatically, creating responsive systems that react to sensor inputs or external events.

The controllers also provide comprehensive error reporting and protection features. Overcurrent detection, stall protection, and thermal monitoring help prevent damage to both the controller and connected motor, while detailed error logs assist with troubleshooting and system optimization. Advanced controllers also include protection against short circuits, such as short to ground or phase to phase, to prevent system damage and improve fault detection.

EZStepper and Industrial Solutions

Higher-end commercial solutions like AllMotion’s EZStepper controllers target industrial applications requiring maximum reliability and advanced features. These systems often support industry-standard protocols such as Cavro DT, facilitating integration with laboratory equipment and industrial automation systems.

Stand-alone operation capabilities allow these controllers to execute complex motion profiles without external computer control. This autonomy becomes critical in applications where system reliability cannot depend on PC availability or network connectivity.

Communication Protocols and Interfaces

The method you choose for communicating with your stepper motor controller significantly impacts system performance, reliability, and implementation complexity. Understanding the strengths and limitations of each interface helps you select the optimal solution for your specific application.

USB Interface Configuration

USB provides the most straightforward path for PC-based stepper motor control, offering high bandwidth and built-in power delivery for many controllers. Most modern stepper controllers appear as virtual COM ports when connected to a computer, allowing standard serial communication programming techniques while benefiting from USB’s reliability and ease of use.

Windows drivers typically install automatically for well-designed controllers, though some industrial devices may require specific driver packages. The USB interface excels in applications requiring frequent parameter changes, real-time monitoring, or high-speed command streaming from PC-based control software.

USB connections also enable firmware updates and comprehensive diagnostics that would be difficult to implement with simpler communication methods. The interface supports plug-and-play operation, making it ideal for portable equipment or systems that need frequent reconfiguration.

TTL Serial Communication

TTL serial communication offers broad compatibility across microcontrollers and embedded systems while maintaining implementation simplicity. Operating at standard baud rates like 9600 or 115200 bits per second, serial interfaces provide reliable communication for most motion control applications without requiring specialized hardware or complex protocols.

The main considerations for serial communication include cable length limitations and potential electromagnetic interference in industrial environments. Proper grounding and shielded cables help maintain signal integrity, while selecting appropriate baud rates balances communication speed with reliability requirements.

Serial interfaces work particularly well in distributed systems where multiple microcontrollers need to coordinate stepper motor movements. The simplicity of serial communication makes it easier to debug communication issues and implement custom protocols for specialized applications.

I²C Implementation Standards

I²C (Inter-Integrated Circuit) communication enables multiple stepper controllers to share a single two-wire bus, dramatically simplifying wiring in multi-axis systems. Following the NXP UM10204 specification ensures compatibility across different controller manufacturers and reduces integration challenges.

Each device on an I²C bus requires a unique address, allowing your control software to communicate with specific motors independently. This addressing capability makes I²C ideal for applications like 3D printers or CNC machines where multiple axes must coordinate precisely but also operate independently.

The I²C interface does have bandwidth limitations compared to USB or high-speed serial connections. However, for most stepper motor control applications, this bandwidth is sufficient while providing the advantage of simplified wiring and robust communication protocols.

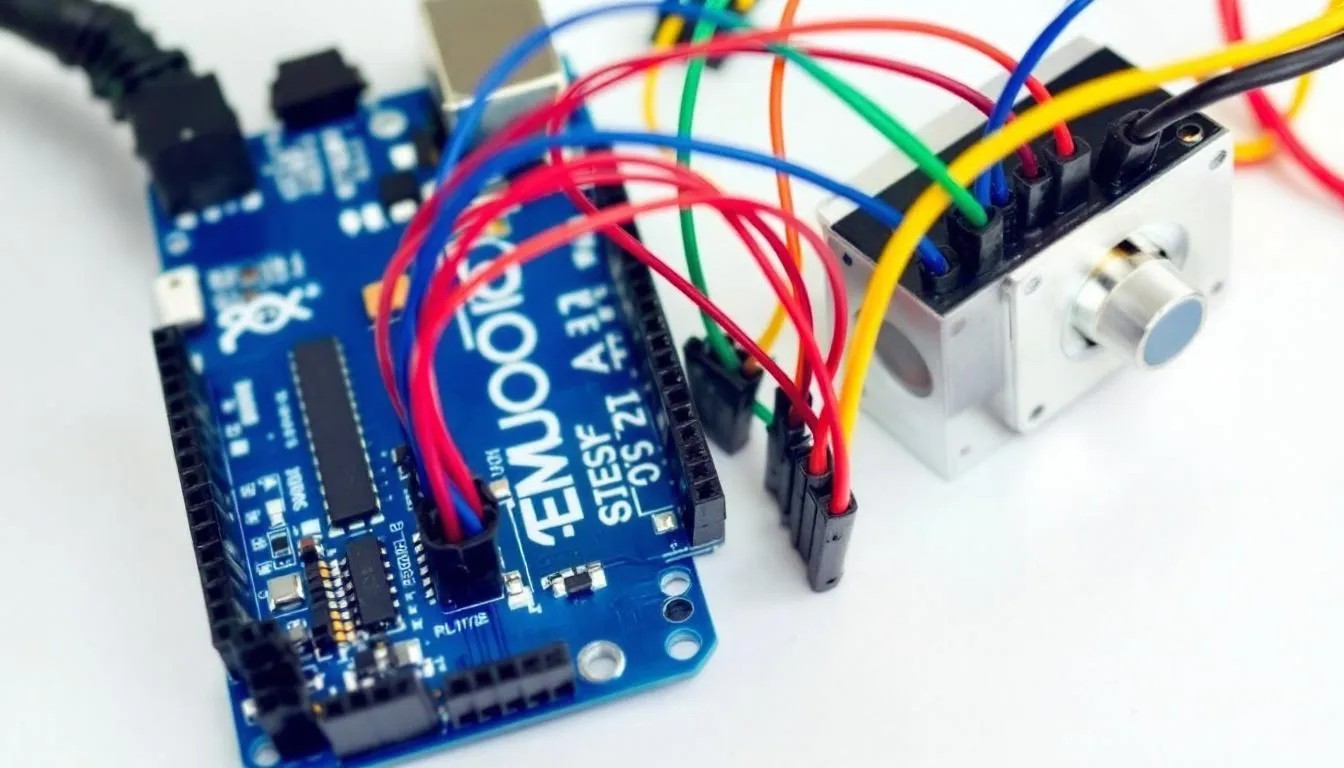

While USB, serial, and I²C cover many projects, industrial motion systems often demand deterministic networking and multi-protocol interoperability—especially when multiple axes must stay synchronized under load. A good example is our stepper motor control software and driver development work for a European 3D printer manufacturer, where we built both the hardware and the embedded software for a stepper driver with EtherCAT support and a configurable multi-interface architecture. Alongside core Step/Dir control, the solution supported selectable microstepping and current settings, multi-stepping for smoother movement, automatic idle-current reduction, and robust protections (overcurrent/overvoltage, reverse input, EMI resilience)—the kinds of features that turn “it moves” into motion control that remains stable in production environments.

Alternative Control Methods

Some applications benefit from analog voltage control interfaces, where a 0-5V signal directly controls motor speed or position. This approach works well with legacy industrial equipment or PLC systems that output analog control signals rather than digital communication.

Quadrature encoder feedback integration represents another important interface option, particularly for closed-loop stepper systems. While traditional steppers operate open-loop, adding encoder feedback enables position verification and automatic correction of missed steps under varying load conditions.

Motion Control Programming Techniques

Sophisticated motion control requires more than simply sending step pulses to your motor. Advanced programming techniques enable smooth, coordinated movements that maximize system performance while protecting mechanical components from excessive stress and wear.

Coordinated Multi-Axis Control

Multi-axis systems like CNC machines and 3D printers require precise coordination between multiple stepper motors to achieve accurate results. Time-based coordination ensures all axes reach their target positions simultaneously, creating smooth diagonal movements and complex curves rather than jerky step-wise motions.

Keyframe animation techniques borrowed from computer graphics provide an elegant solution for complex motion sequences. Your software defines key positions and timing, then interpolates the intermediate steps needed to achieve smooth motion along the desired path. This approach works particularly well for applications like camera sliders or robotic arms where smooth motion is essential for professional results.

The following pseudocode illustrates coordinated motion planning:

Acceleration Profile Implementation

Real-Time Motion Planning

Custom Application Development

CNC and 3D printer applications represent the most demanding stepper motor control scenarios, requiring software that can interpret G-code commands and translate them into coordinated motor movements. Custom software development for these applications involves parsing command files, planning tool paths, and managing multiple axes simultaneously.

Loop execution capabilities allow repetitive operations without continuous command streaming from the host computer. The software can store motion sequences locally and repeat them based on external triggers or timing requirements.

Switch-triggered halt programming provides essential safety features for automated systems. Emergency stop inputs must be able to halt all motion immediately while maintaining position knowledge for safe system restart.

Software Development Tools and Resources

Success with stepper motor software depends heavily on having access to comprehensive documentation, example code, and troubleshooting resources. The best platforms provide extensive support materials that accelerate development and reduce the learning curve for new users.

Documentation and Source Code

High-quality stepper motor software platforms provide detailed source code repositories that allow you to understand exactly how the software works and customize it for your specific needs. GitHub and similar platforms host extensive collections of libraries, example projects, and community contributions that can serve as starting points for your own development.

Build instructions for custom applications typically include step-by-step guides for compiling software, configuring development environments, and integrating with different hardware platforms. These resources are particularly valuable when working with embedded systems where the development process differs significantly from standard PC programming.

Version control and change logs help you track software updates and understand how new features or bug fixes might affect your existing projects. Well-maintained platforms provide clear migration guides when upgrading to newer software versions.

Hardware Integration Resources

3D CAD models and DXF drilling guides simplify the mechanical integration of stepper controllers into your projects. These resources eliminate the guesswork involved in designing enclosures or mounting systems, reducing development time and improving professional appearance.

Schematic diagrams and pin-out documentation ensure proper electrical connections between your software, controller, and motor. Incorrect wiring is one of the most common causes of stepper motor system failures, making accurate documentation essential for reliable operation.

Many manufacturers provide PCB layout files and reference designs that demonstrate best practices for integrating their controllers into custom circuit boards. These resources are particularly valuable for production systems where custom hardware provides advantages over development boards.

Educational Resources and Tutorials

Video tutorials offer step-by-step guidance for getting started with specific stepper motor controllers and software platforms. These visual guides can be particularly helpful for understanding the physical setup and configuration process that text documentation might not convey clearly.

Printable PDF user manuals provide offline reference materials that you can access without internet connectivity. This documentation often includes troubleshooting flowcharts, parameter tables, and quick reference guides that speed up development and debugging processes.

Online communities and forums provide access to experienced users who can help solve specific problems or suggest alternative approaches to challenging applications. Users can post a question about hardware, software, or programming approaches and receive troubleshooting help from experienced community members. Active communities also serve as sources of new techniques, bug reports, and feature requests that drive software platform improvements.

Development Environment Setup

Proper development environment configuration ensures reliable software compilation and deployment. This includes installing the correct compiler versions, setting up hardware debugging interfaces, and configuring communication drivers for your target platform.

Cross-platform compatibility considerations become important when developing software that needs to run on different operating systems or hardware architectures. Understanding the limitations and requirements of each target platform helps avoid compatibility issues during deployment.

Troubleshooting and Optimization

Even well-designed stepper motor software can encounter issues that prevent proper operation. Understanding common problems and their solutions helps you quickly diagnose and resolve issues that could otherwise halt your project progress.

Common Configuration Issues

Incorrect step resolution settings represent one of the most frequent sources of stepper motor problems. The software must match the microstepping configuration set on your motor driver, or the motor will move incorrect distances or exhibit erratic behavior. Always verify that your software step calculations align with your hardware microstepping settings.

Maximum speed and acceleration parameters require careful tuning to match your motor’s capabilities and mechanical load characteristics. Setting these values too high results in missed steps and position errors, while overly conservative settings reduce system throughput unnecessarily.

Current limiting settings in software must coordinate with the current limit switches or digital settings on your motor driver. Mismatched current settings can cause overheating, insufficient torque, or driver protection shutdowns that interrupt normal operation.

Performance Optimization Strategies

High-speed applications require careful attention to software timing and processor loading. Microcontroller firmware must generate step pulses with precise timing while leaving sufficient processing power for other system functions. Hardware timers and interrupt-driven routines often provide better timing accuracy than software loops.

Multi-axis coordination becomes challenging at high speeds where the software must calculate and output multiple pulse streams simultaneously. Dedicated motion control processors or FPGA-based solutions may be necessary for the most demanding applications.

Code profiling helps identify bottlenecks in your software that limit system performance. Understanding where your software spends its time enables targeted optimizations that improve overall system capability without extensive redesign.

Power Management and Thermal Considerations

Software-controlled power management extends system operating life and reduces energy consumption. Adaptive current limiting reduces motor heating during idle periods while maintaining holding torque. Sleep modes can power down unused controllers in multi-axis systems.

Thermal monitoring through software enables proactive protection against overheating conditions. Some controllers provide temperature feedback that your software can use to reduce current limits or stop operation before damage occurs.

Battery-powered applications require sophisticated power management algorithms that balance performance with operating time. Software can implement multiple power modes that trade speed and torque for extended battery life.

Diagnostic and Debugging Tools

Status monitoring capabilities built into modern stepper controllers provide valuable troubleshooting information. Error flags can indicate overcurrent conditions, stall detection, or communication failures that help isolate the source of system problems.

Real-time position feedback allows you to verify that commanded movements are being executed correctly. Comparing commanded versus actual positions can reveal mechanical problems, missed steps, or incorrect configuration parameters.

Communication debugging tools help diagnose interface problems between your control software and motor controllers. Protocol analyzers and communication logs can reveal timing issues, incorrect command formats, or electrical interface problems.

Future Trends in Stepper Motor Software

The evolution of stepper motor software continues accelerating as new technologies create opportunities for enhanced functionality and easier implementation. Understanding these trends helps you select platforms and techniques that will remain relevant as technology advances.

IoT Integration and Connectivity

ESP32 modules and similar WiFi-enabled microcontrollers are revolutionizing stepper motor control by enabling wireless communication and internet connectivity. These platforms allow you to control motors remotely, monitor system status from anywhere, and integrate stepper control into larger IoT ecosystems.

Cloud-based control systems enable centralized management of distributed stepper motor installations. Manufacturing facilities can monitor and control hundreds of motors from a single interface, while predictive maintenance algorithms analyze performance data to prevent failures before they occur.

Smartphone app development for stepper motor control represents a growing trend toward user-friendly interfaces. Mobile apps can provide intuitive control interfaces that make complex motion control accessible to non-technical users while maintaining the precision required for professional applications.

Machine Learning and Adaptive Control

Artificial intelligence applications in motion control promise significant improvements in system optimization and fault tolerance. Machine learning algorithms can analyze historical performance data to optimize acceleration profiles, predict maintenance requirements, and automatically tune control parameters for changing conditions.

Adaptive control systems use real-time feedback to continuously improve motion accuracy and efficiency. These systems can compensate for mechanical wear, temperature effects, and load variations automatically, maintaining optimal performance throughout the system’s operating life.

Predictive maintenance algorithms analyze motor current signatures, vibration patterns, and performance metrics to identify developing problems before they cause system failures. This capability reduces downtime and maintenance costs while improving overall system reliability.

Enhanced User Interfaces and Integration

Modern stepper motor software increasingly emphasizes ease of use without sacrificing functionality. Graphical programming interfaces allow users to create complex motion sequences through drag-and-drop operations rather than traditional coding.

CAD workflow integration enables direct import of tool paths and motion sequences from design software. This seamless integration reduces errors and development time while ensuring that manufactured parts match design specifications exactly.

Over-the-air update capabilities allow software improvements and feature additions without physical access to deployed systems. This capability is particularly valuable for remote installations or systems that are difficult to access for maintenance.

Standardization and Interoperability

Industry efforts toward standardized communication protocols and configuration formats aim to improve compatibility between different manufacturers’ hardware and software. These standards reduce vendor lock-in and simplify system integration.

Open-source hardware and software initiatives continue expanding the available options for stepper motor control while reducing costs and increasing customization possibilities. These platforms often pioneer new features that eventually appear in commercial solutions.

Cross-platform compatibility ensures that software investments remain viable as hardware platforms evolve. Modern stepper motor software increasingly runs on multiple operating systems and processor architectures without modification.

Conclusion

Stepper motor software serves as the crucial link between digital commands and precise mechanical motion, enabling everything from hobbyist 3D printers to industrial automation systems. The landscape spans from accessible Arduino libraries that get beginners started quickly to sophisticated commercial platforms that power mission-critical applications.

Success with stepper motor software depends on matching the platform capabilities to your specific requirements. Arduino’s AccelStepper library excels for prototyping and educational projects, while commercial solutions like Pololu’s Tic series provide the reliability and advanced features needed for professional applications. Understanding communication protocols, programming techniques, and optimization strategies ensures your system achieves the precision and performance your application demands.

The future of stepper motor software points toward increased connectivity, artificial intelligence integration, and user-friendly interfaces that make precision motion control accessible to broader audiences. Whether you’re building your first automated system or optimizing an existing installation, the key lies in choosing software that not only meets today’s requirements but can adapt to tomorrow’s opportunities.

Start by identifying your specific needs—precision requirements, communication interfaces, and integration challenges—then select the software platform that best addresses these concerns. With the right foundation in place, you’ll find that precise, reliable motion control opens doors to automation possibilities you may never have considered before.

Our Case Studies