Zero-Latency Edge FPGA Networks: Redefining Real-Time Control in 5D Printing

5D printing is one of the most exciting frontiers in manufacturing — not just because it adds two more degrees of freedom to the traditional 3D process, but because it fundamentally changes how machines must think, react, and synchronize.

Unlike standard additive systems that move layer by layer, 5D printing involves continuous curvature, dynamic reorientation of print heads, and real-time feedback loops from multiple axes operating simultaneously.

To make this possible, the control infrastructure has to evolve far beyond standard motion controllers or PLCs. The system must operate at sub-millisecond precision — with distributed nodes that talk to each other instantly, without the latency or jitter of software-based communication. This is where edge FPGA networks come into play.

They bring real-time determinism, hardware-level adaptability, and parallel signal processing that traditional CPU or MCU-based systems simply can’t achieve. Let’s look at how zero-latency FPGA architectures are reshaping 5D printing control — from machine synchronization to data analytics at the edge.

The challenge: real-time control beyond three axes

In conventional 3D printing, the control system synchronizes three or four motors at a relatively fixed rate, usually around 1–10 kHz. Each motor follows a trajectory calculated by a central controller. That’s already complex — but manageable.

Now imagine a 5D printer with dynamic toolpaths, continuously rotating print heads, and multiple independent motion subsystems. The printhead orientation changes in real-time to maintain the optimal deposition angle, and multiple sensors (temperature, pressure, vibration, surface mapping) continuously feed back data to modify that motion.

A centralized CPU-based control model simply can’t keep up. Even a 1 ms delay can cause misalignment, surface defects, or structural inconsistencies in the printed part. The system needs hardware-level coordination — meaning computation, communication, and actuation must all happen in deterministic time.

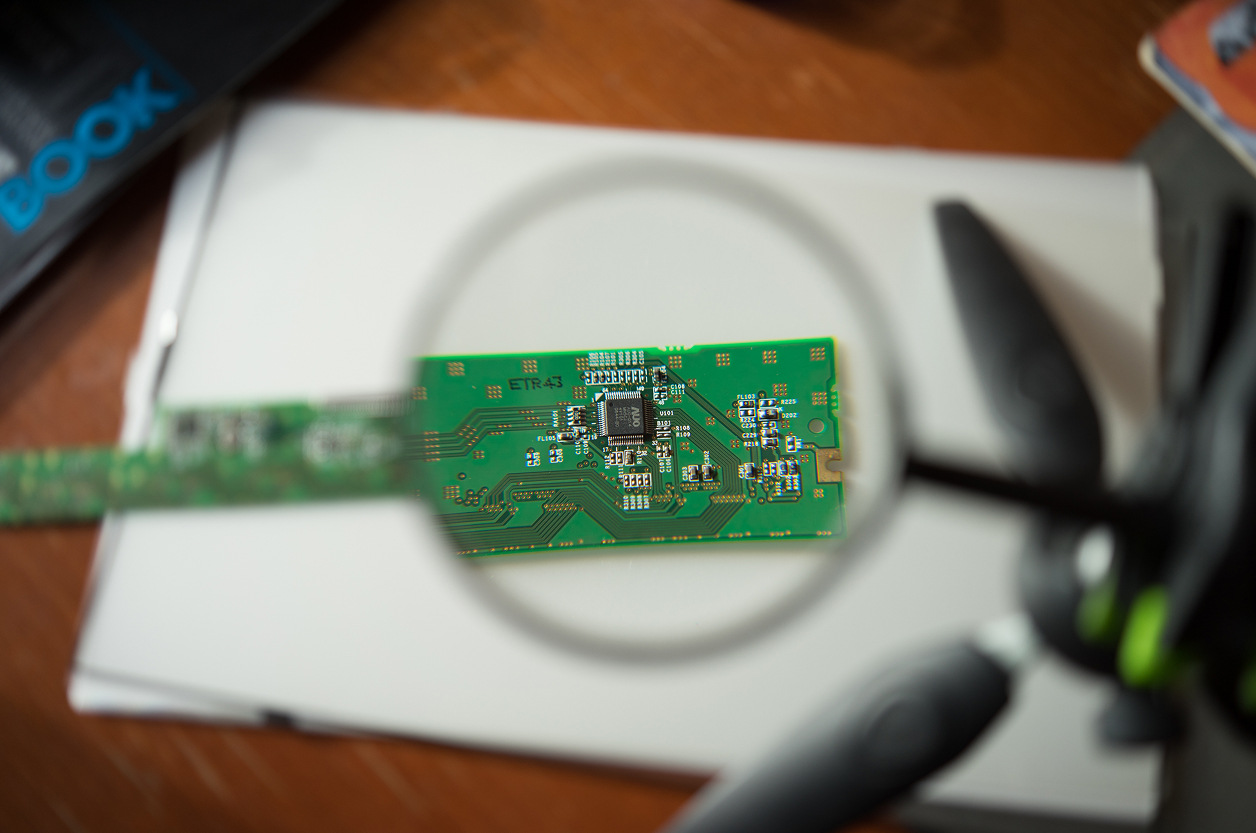

FPGA (Field-Programmable Gate Array) devices solve this by allowing parallel data paths and ultra-fast signal response times. But a single FPGA isn’t enough anymore. In large-scale additive systems, especially those with modular print heads, distributed FPGA nodes interconnected in a zero-latency edge network create the new backbone of real-time control.

Why FPGAs are the core of next-generation 5D printing

FPGAs are uniquely suited for the demands of 5D printing for three reasons:

- Parallelism: Unlike CPUs, which process one instruction at a time, FPGAs can execute hundreds of control operations simultaneously.

- Deterministic timing: Each operation happens within a fixed number of clock cycles — no OS delays, no unpredictable scheduling.

- Reconfigurability: Engineers can reprogram the hardware logic to adapt to different materials, print head designs, or machine configurations without changing the entire system.

This means FPGAs can handle motor control, sensor fusion, and real-time feedback in hardware, bypassing the bottlenecks of software control loops.

In the context of 5D printing, that translates into:

- smoother toolpath execution,

- real-time compensation for vibration or thermal drift, and

- perfect synchronization across all motion axes.

But what makes the new generation of systems revolutionary is not just the FPGA itself — it’s the network that connects them.

The rise of zero-latency edge FPGA networks

In a modern 5D printing line, every module — whether it’s a print head, robotic manipulator, or sensor cluster — often has its own embedded FPGA. Each FPGA processes data locally and exchanges state information with neighboring nodes through ultra-fast deterministic links.

This architecture eliminates the need for a single master controller. Instead, intelligence is distributed: every node understands the global context, but reacts locally.

Key technical principles:

- Deterministic communication: Instead of using traditional Ethernet or fieldbuses, systems use FPGA-to-FPGA serial transceivers or time-sensitive networking (TSN) with sub-microsecond jitter.

- Synchronous clock domains: All nodes share a hardware-synchronized clock, ensuring nanosecond-level alignment between motion commands and sensor updates.

- Direct hardware handshaking: Control messages propagate as electrical signals, not packets, enabling effectively zero latency for motion feedback.

- Edge inference: Some systems now integrate AI accelerators within FPGA fabric to adjust toolpaths in real time based on sensor data.

These capabilities allow a network of FPGAs to behave as a single distributed control organism — scalable, self-coordinating, and adaptive to process variations.

Inside a real-world 5D printing control loop

A zero-latency 5D printing controller operates in a closed feedback loop. Let’s break it down:

- Sensor fusion layer: Cameras, strain gauges, thermal sensors, and laser scanners continuously monitor material deposition, temperature gradients, and surface topology.

- FPGA-based signal preprocessing: Each FPGA node filters raw signals, removes noise, and extracts relevant metrics directly in hardware.

- Real-time synchronization: The processed data is shared across the FPGA network. Adjustments to printhead motion or extrusion parameters are made within microseconds.

- Predictive correction: Embedded algorithms (sometimes implemented as AI logic blocks) anticipate mechanical oscillations or deviations and compensate before they occur.

- Verification and adaptation: The system validates results on the fly — adapting feed rates, nozzle angles, or actuator torque without interrupting the process.

This feedback cycle runs continuously — hundreds of times per second — maintaining accuracy and repeatability even in geometries impossible for conventional printing systems.

Advantages over CPU- and GPU-based controllers

While CPUs are flexible and GPUs are powerful, neither offers the combination of low latency, determinism, and reliability required in real-time manufacturing control.

FPGA-based networks outperform them in several critical aspects:

| Criterion | CPU Controller | GPU Controller | FPGA Edge Network |

| Latency | 1–10 ms | ~1 ms | < 1 µs |

| Determinism | Non-deterministic | Moderate | Fully deterministic |

| Parallel Processing | Limited | High (software) | Native (hardware) |

| Reconfiguration | Software-based | Software | Hardware logic-level |

| Failure Isolation | Centralized | Centralized | Distributed, node-based |

This makes edge FPGA networks not just faster, but inherently more resilient — a single node can fail or reconfigure without halting the system.

Engineering challenges and design trade-offs

As promising as the concept is, implementing zero-latency FPGA networks for 5D printing introduces several engineering complexities:

- Clock synchronization: Maintaining nanosecond-level timing across multiple boards requires precision reference clocks and deterministic link calibration.

- Communication topology: Fully meshed networks minimize latency but increase PCB complexity and routing costs. Hierarchical topologies offer better scalability.

- Thermal and power constraints: Parallel hardware execution demands significant power; managing heat in dense FPGA arrays is critical.

- Firmware orchestration: Updating distributed bitstreams in real-time while maintaining operational continuity requires advanced versioning and rollback mechanisms.

- Toolchain maturity: High-level synthesis (HLS) tools for FPGA design are improving, but developing hardware logic for real-time systems still requires specialized expertise.

Despite these challenges, companies pioneering this architecture — particularly in aerospace-grade additive manufacturing and precision robotics — report order-of-magnitude improvements in stability and throughput.

The road to fully autonomous 5D fabrication

Zero-latency FPGA networks are not just about speed — they enable new design possibilities.

Imagine a 5D printer that continuously adjusts material composition, deposition angle, and curing energy in real time — all driven by embedded intelligence running at the hardware level.

Future systems may integrate:

- Hybrid FPGA-SoC modules for combined control and AI processing;

- Optical interconnects between nodes for nanosecond synchronization;

- Self-calibrating feedback using embedded ML models;

- Predictive redundancy where each FPGA anticipates potential failures in its neighbors and compensates instantly.

Such architectures could make it possible to manufacture structures that adapt their geometry and material properties dynamically during fabrication — a fundamental leap toward autonomous, self-optimizing production lines.

Impact on industrial automation

In broader industrial contexts, zero-latency FPGA control networks can transform not just additive manufacturing, but any process requiring extreme synchronization: multi-axis robotics, semiconductor lithography, adaptive optics, and automated inspection systems.

By decentralizing intelligence, factories gain:

- Shorter control loops with near-zero communication delays;

- Higher reliability through localized fault tolerance;

- Faster commissioning via modular hardware;

- Predictable timing for machine learning at the edge.

It’s a shift similar to what happened in computing decades ago — from mainframes to distributed networks — only now it’s happening inside machines themselves.

Why it matters now

As industries adopt more complex materials and hybrid manufacturing processes, precision requirements move into the sub-micron domain. Traditional control systems — even those based on high-end CPUs — cannot guarantee deterministic responses under fluctuating workloads or high data rates.

Edge FPGA networks fill this gap, giving engineers direct control over latency, bandwidth, and computation. They also align with the industry’s broader move toward hardware-accelerated autonomy — embedding intelligence not in the cloud, but right next to the process.

For 5D printing, this isn’t optional — it’s the only way to ensure smooth, accurate, and adaptive operation at industrial scale.

AI Overview: Zero-Latency Edge FPGA Networks for 5D Printing

Edge FPGA networks eliminate latency barriers in 5D printing by enabling hardware-level synchronization and distributed intelligence across motion and sensor nodes.

Key Applications: 5D additive manufacturing, precision robotics, semiconductor lithography, real-time optical alignment, high-speed industrial automation.

Benefits: sub-microsecond response, perfect motion synchronization, scalable distributed control, predictive fault tolerance, edge-level autonomy.

Challenges: complex synchronization, high design cost, power management, firmware orchestration across FPGA clusters.

Outlook: by 2030, FPGA-based control networks will form the core of next-generation industrial machines, where real-time intelligence and zero-latency coordination become the default.

Related Terms: edge FPGA, deterministic networking, time-sensitive control, 5D printing architecture, distributed motion system, hardware-level AI.

Our Case Studies