Promwad Joins CC-Link Partner Association for Industrial Automation Projects

For our industrial automation clients, Promwad's membership in CLPA gives access to the latest advances in CC-Link technologies. In addition, CLPA affiliation guarantees compatibility of our products with a wide range of devices, compliance with international ISO and IEC standards, and extensive technical support.

CC-Link (Control & Communication Link) is critical in developing industrial networks with CC-Link network technologies for our clients in power management, industrial automation, and smart buildings.

As a result, Promwad engineers cover all popular industrial communication networks, including fieldbus systems, safety networks, and industrial Ethernet, to provide real-time control and high-speed data exchange in various environments.

What is СС-Link partner association?

The CC-Link Partner Association (CLPA) promotes open communication standards and aims to foster the creation and practical use of the CC-Link family of open industrial network technologies. It has 2,800+ member companies with 1,500+ certified products from hundreds of manufacturers.

CC-Link gives a framework for seamless communication between various automation devices in industrial, including fieldbus systems, safety networks, and industrial Ethernet technologies.

“CLPA was created to support and manage the CC-Link technology and its ecosystem. It creates specifications, provides technical support and certification services to ensure compatibility between products from different vendors. Their work is essential for us and our clients, since we require reliable, high-speed communications networks for real-time control applications”, said Roman Shuliankou, Head of Industrial Automation Unit at Promwad.

The association also promotes adopting CC-Link network technology through various marketing and educational initiatives. It offers companies a platform to demonstrate their products and solutions, which increases visibility and builds networking within the industrial automation community.

Why is CC-Link important for our clients?

Promwad’s clients in the industrial automation field benefit greatly from our membership in the CC-Link Partner Association:

Advanced technologies. As a CLPA member, we have direct access to the latest developments in CC-Link technologies, including high-speed, deterministic communication protocols like CC-Link IE TSN. We can integrate cutting-edge networking capabilities for better performance, reliability, and real-time control in automation systems.

Compatibility. This membership ensures that products and solutions designed at Promwad are compatible with a wide range of devices and systems from other manufacturers. It is important for integrating new systems into existing setups.

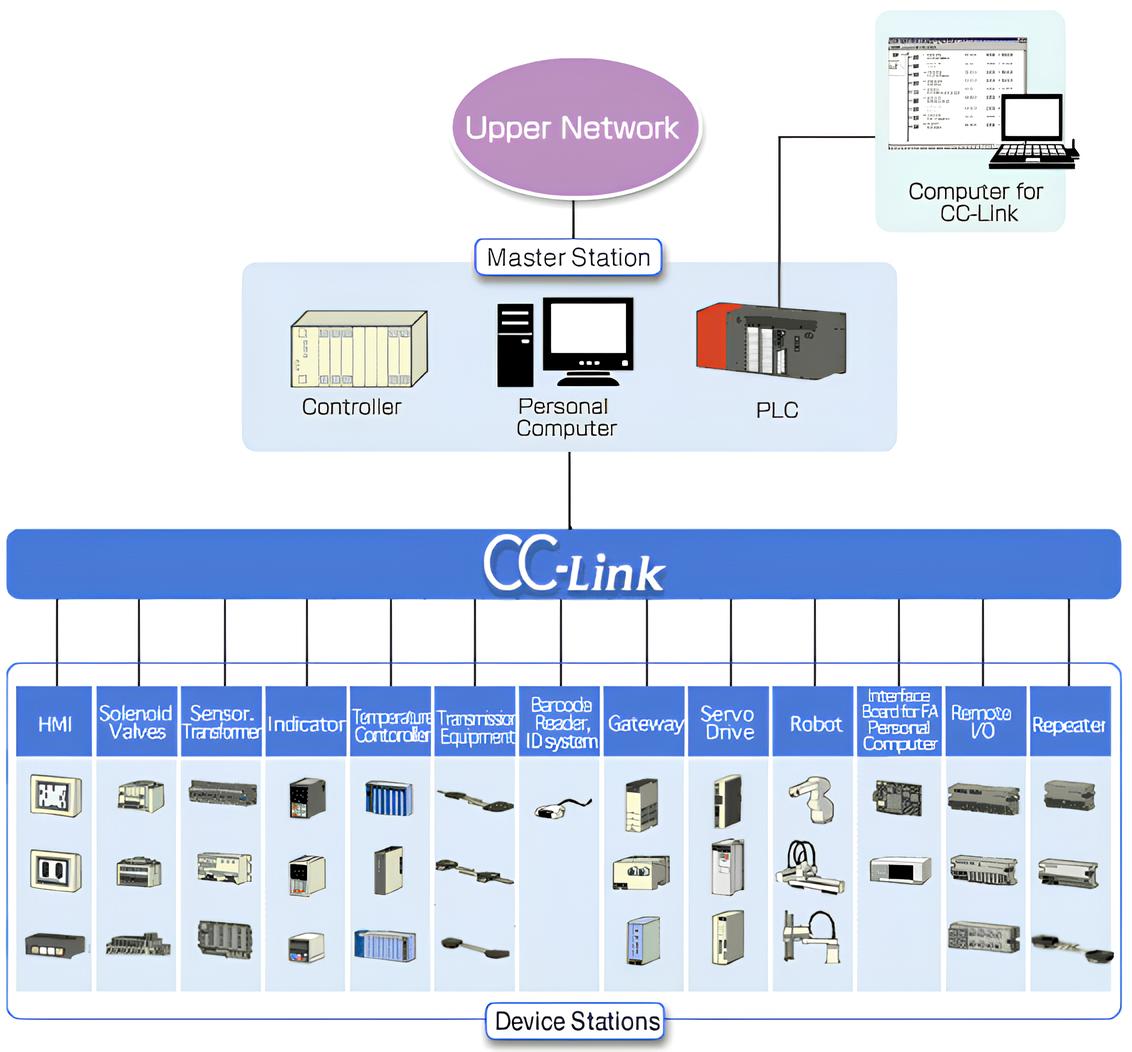

The CC-Link configuration diagram shows flexible manufacturing line setups using products from different vendors. Source: сс-link.org

Standard compliance. The CLPA adheres to internationally recognised standards, including ISO and IEC.

Technical support. Promwad has access to extensive technical support and resources, latest specifications and certification processes. This enables us to offer better support and service to our customers, ensuring that they receive well-documented, certified, and high-quality products.

Application areas

With CC-Link's reliability and high-speed communication capabilities, it is frequently used in many industrial automation applications. We give some examples of projects where CC-Link can be used effectively:

- Manufacturing automation

CC-Link can be used to coordinate robots, conveyor systems and other equipment to optimise assembly processes. In the food and beverage industry, CC-Link networks manage complex packaging lines, integrating sensors, actuators and control systems for accurate packaging, labelling and quality assurance.

- Control systems

CC-Link carries out the advanced data exchange required in the chemical and medical industries. It precisely controls temperature, pressure, environmental conditions, and substance mixing. CC-Link also supports stringent regulatory requirements for controlling and monitoring manufacturing processes.

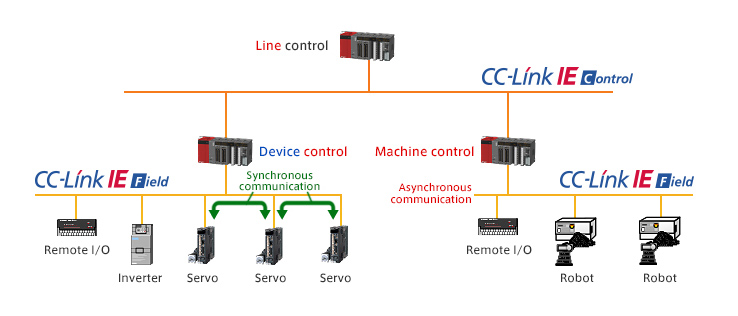

Synchronous control across the CC-Link IE Field network. Source: cc-link.org

- Material handling

CC-Link can be used to coordinate automated guided vehicles (AGVs), conveyor systems, and robotic arms in warehouses for efficient and accurate handling, storage, and retrieval of goods.

- Energy management

CC-Link can be used in solar and wind farms for real-time control and monitoring of equipment such as inverters, transformers and power distribution systems.

- Building automation

In building automation, CC-Link networks can interconnect various systems such as HVAC, lighting, security, and access control to provide centralised monitoring and control, improving the building's energy efficiency and manageability.

***

The CC-Link Partner Association (CLPA) continuously enhances the capabilities and safety of industrial automation through its comprehensive support of CC-Link technologies. CLPA membership allows us to provide our clients with state-of-the-art solutions that meet the highest quality and performance standards.

Contact us today to discover more about how we can help you apply CC-Link's capabilities to your industrial automation challenges!