Configurable Access Control Layouts: Just Software, No Panel Replacement

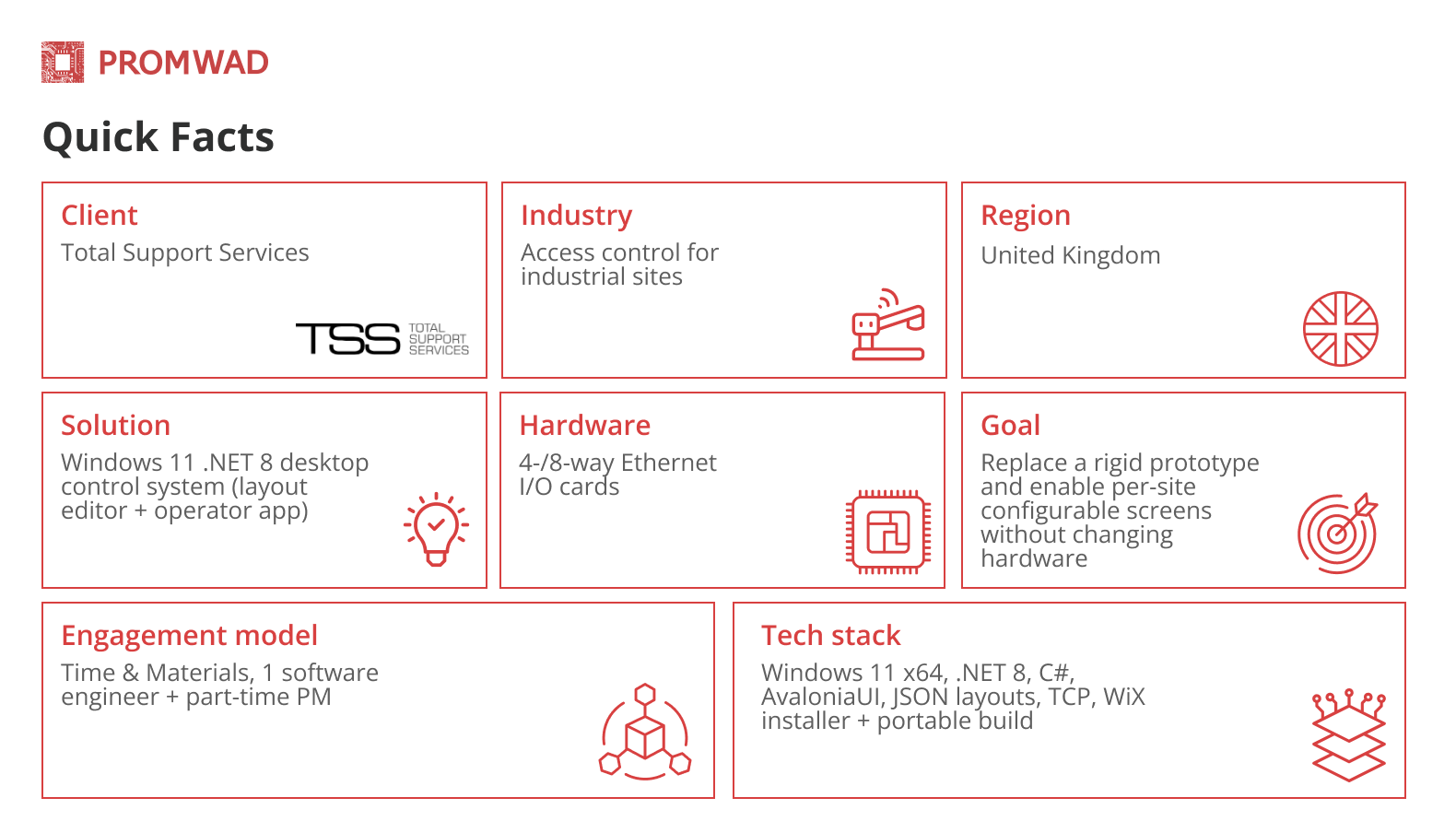

Project in a Nutshell: Promwad developed a configurable Windows 11 control system for Total Support Services, a UK-based security and facilities services provider. We built a .NET 8 desktop solution with a layout editor and operator app to control 4-way and 8-way I/O cards from industrial PCs. It replaced a rigid prototype and now lets engineers adapt screens and logic per site without changing the hardware or code.

As a result, Total Support Services has a maintainable, easily deployable tool that meets their end customers’ gate and barrier control needs and can be extended further.

Client & Challenge

Our client, Total Support Services, is a UK-based security and facilities services provider that supplies and maintains access control systems for industrial sites. For one of their end customers, they needed a reliable way to control gates and barriers using industrial PCs connected to 4-way and 8-way I/O cards. The existing Windows prototype was hard to adapt to different sites, difficult to maintain and extend, and did not give engineers enough flexibility to design and update control screens.

They were looking for a system that would work with the chosen relay hardware, let engineers configure and evolve control layouts without changing the code, and remain simple to install and support for their own service team.

They chose Promwad as a development partner thanks to our experience in .NET desktop tools for industrial automation and our pragmatic approach: we could build on their existing controllers and UI concept, stay within the agreed budget, and remain flexible as project priorities evolved.

Solution

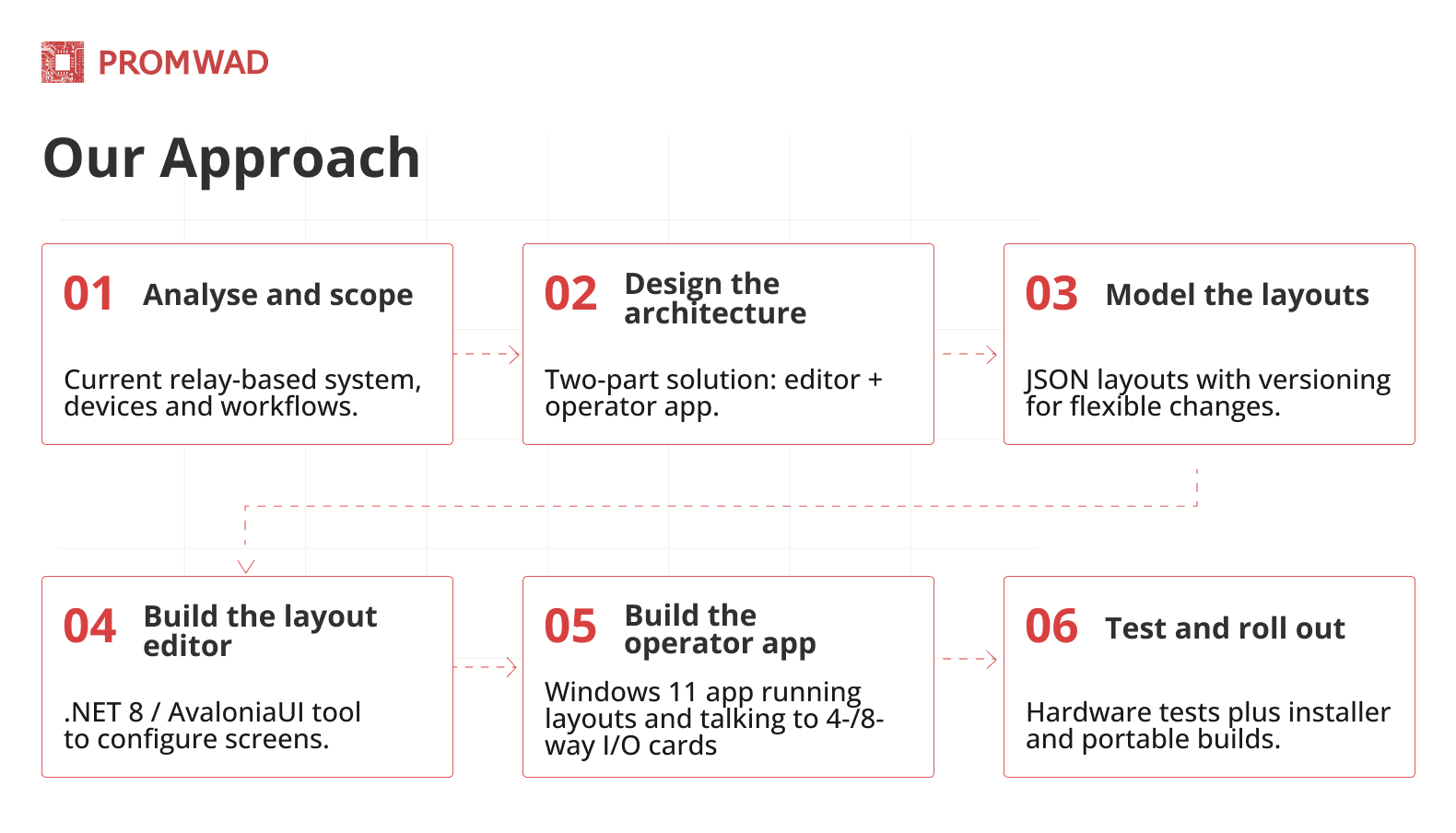

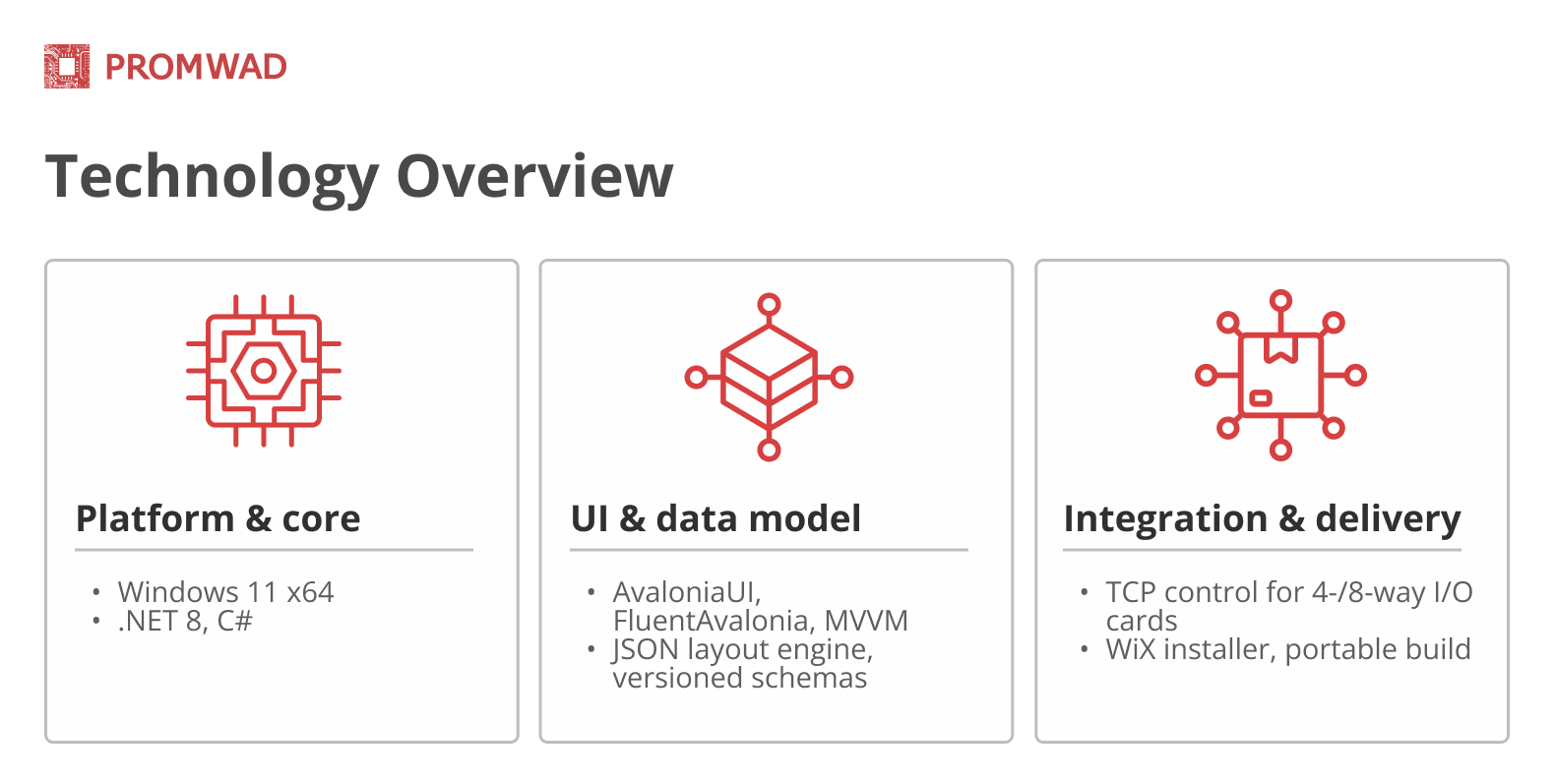

We built a configurable control system for Windows 11 on .NET 8. It has two parts:

- A visual layout editor where engineers design relay-based control screens as JSON layouts.

- A full-screen operator app that runs these layouts on industrial PCs and works with 4-way and 8-way I/O cards over TCP.

This design gives the client:

- A versioned JSON layout model with automatic upgrades, so existing installations keep working while new screens and components appear.

- A separate TCP command layer for the 4-way and 8-way I/O cards, which keeps the interface responsive even when the network is unstable.

- Two delivery options — a WiX-based installer and a portable build — so the service team can update systems on site without extra tools.

During development, we had to solve a few practical issues:

- Work with unreliable TCP connections to relay controllers without freezing the UI or leaving relays in an unknown state.

- Change and extend layouts and control logic while keeping older JSON configurations valid.

- Pack everything so that installation and updates on industrial PCs are simple for the client’s own service team.

This project is part of our custom software development for industrial automation and robotics expertise. We build maintainable .NET desktop tools for industrial PCs. With this system, the client can update multi-site installations by editing layouts in software, without replacing relay panels or modifying code.

Business Value

The new software provides our client with an up-to-date relay control application tailored to the gate and barrier systems they support, so it integrates seamlessly into their existing operations. It is used for remote opening of barriers and for smoother day-to-day access for the end customer’s staff. The feedback from the end customer has been positive, with further extensions of the application already planned. For the client, it is a customised, cost-effective solution built around their current hardware and layouts, showing that similar projects can be delivered within a defined budget without overhauling the whole system.

More of What We Do for Industrial Software Development

- Qt-Based Solutions: learn about Promwad's expertise in developing SCADA systems, HMI software, and robotics using Qt tools.

- Fire Alarm System Development: сheck out this example of software development using Qt Creator and seven modular boards.

- 5 Reasons to Use Rust: explore our research on the advantages of Rust across industries, from space to blockchain.

FAQ

What industrial automation software do you develop?

We build custom software for PLC, SCADA, MES, and ERP solutions, as well as robotics- and industrial-network–driven systems. Our teams adapt the solution to your application area (e.g., power engineering, building automation, security, industrial networks).

What industrial networks and protocols do you integrate?

We work with PROFINET, EtherCAT, IO-Link, and Modbus TCP/RTU, and can integrate other industrial networks as required. We also support data-exchange layers commonly used in IIoT/industrial systems (e.g., OPC UA, MQTT).

What expertise do you have in control algorithms and low-level engineering?

We work with automatic control theory, electric drives, FPGA-based algorithms, DSP mathematics, and power-system algorithms. This includes motor control approaches such as field-oriented control (FOC) for PMSM, ACIM, and BLDC.

Do you build PLC/SCADA development tools and IDEs?

We develop PLC software aligned with IEC 61131-3 and can create IDEs and tooling for PLC/SCADA programming. This includes work with established runtimes/frameworks and custom IDE development in languages such as C/C++ and Rust.

Can you develop software for power engineering and energy management?

We design energy management platforms for optimisation and consumption regulation across industrial sites and smart-building scenarios. Solutions can be built on modular frameworks (e.g., OpenEMS) to simplify expansion and device/protocol integration.