Sensors 2.0: How Next-Generation Sensors Transform Industrial Systems

The new era of industrial sensing

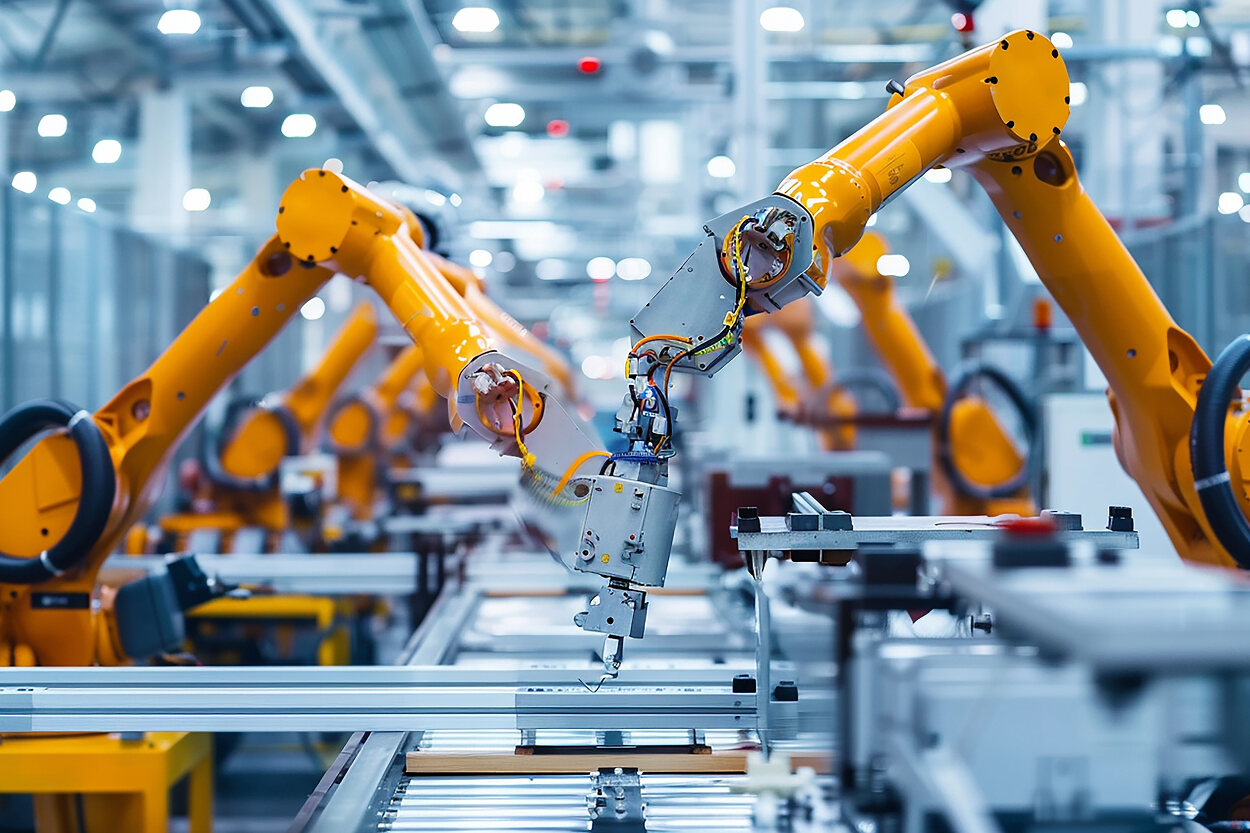

Industrial systems have always depended on sensors, but the role they play today is fundamentally different from the role they played twenty or even ten years ago. The first generations of sensors were simple, deterministic devices designed to capture a single metric and pass it downstream. They acted as the eyes and ears of the factory, but the brain lived elsewhere: inside controllers, PLCs or supervisory systems. The emergence of what many now call Sensors 2.0 has dramatically reshaped this paradigm. These modern sensing devices are no longer passive components; they are intelligent, context-aware, often computationally capable nodes that participate directly in industrial decision-making. They generate richer data, process more information at the edge, communicate more dynamically and enable systems to adapt to their environment in ways older generations never could.

This transformation aligns with broader shifts in industrial architecture. As factories become more connected and distributed, the pressure grows to move intelligence closer to the physical process. Sensors 2.0 sit at the very bottom of this stack, providing real-time insights that feed edge computing, machine learning and advanced automation layers. They allow industrial systems to perceive the world with unprecedented precision and nuance. The question for many manufacturers is not whether these new sensors are necessary, but how quickly they can be deployed at scale across legacy environments that were never designed for such capabilities.

Why traditional sensors reached their limits

Legacy sensors were designed for predictable processes. They measured temperature, pressure, flow, vibration or position with acceptable accuracy for slow-changing environments. But modern manufacturing lines operate faster, with tighter tolerances and greater variability. Traditional sensing architectures cannot handle the complexity of real-time quality control, anomaly detection or multi-variable optimisation.

Another key limitation is bandwidth. Older sensors often output only a small set of values, losing context that would be extremely valuable for analytics or machine learning. They cannot describe trends, patterns or subtle transitions. They do not provide metadata or diagnostic insight. Worse, in many cases they lack the communication capabilities needed for industrial IoT environments, making them isolated components in systems increasingly expected to collaborate. Sensors 2.0 emerge as an answer to these constraints by combining higher fidelity, embedded processing and richer communication protocols.

How Sensors 2.0 introduce intelligence at the edge

One of the most defining characteristics of next-generation sensors is their ability to process information locally before transmitting it. Instead of acting as data collectors, they become data interpreters. This edge-level intelligence reduces the latency of critical decisions and dramatically lowers the load on upstream systems.

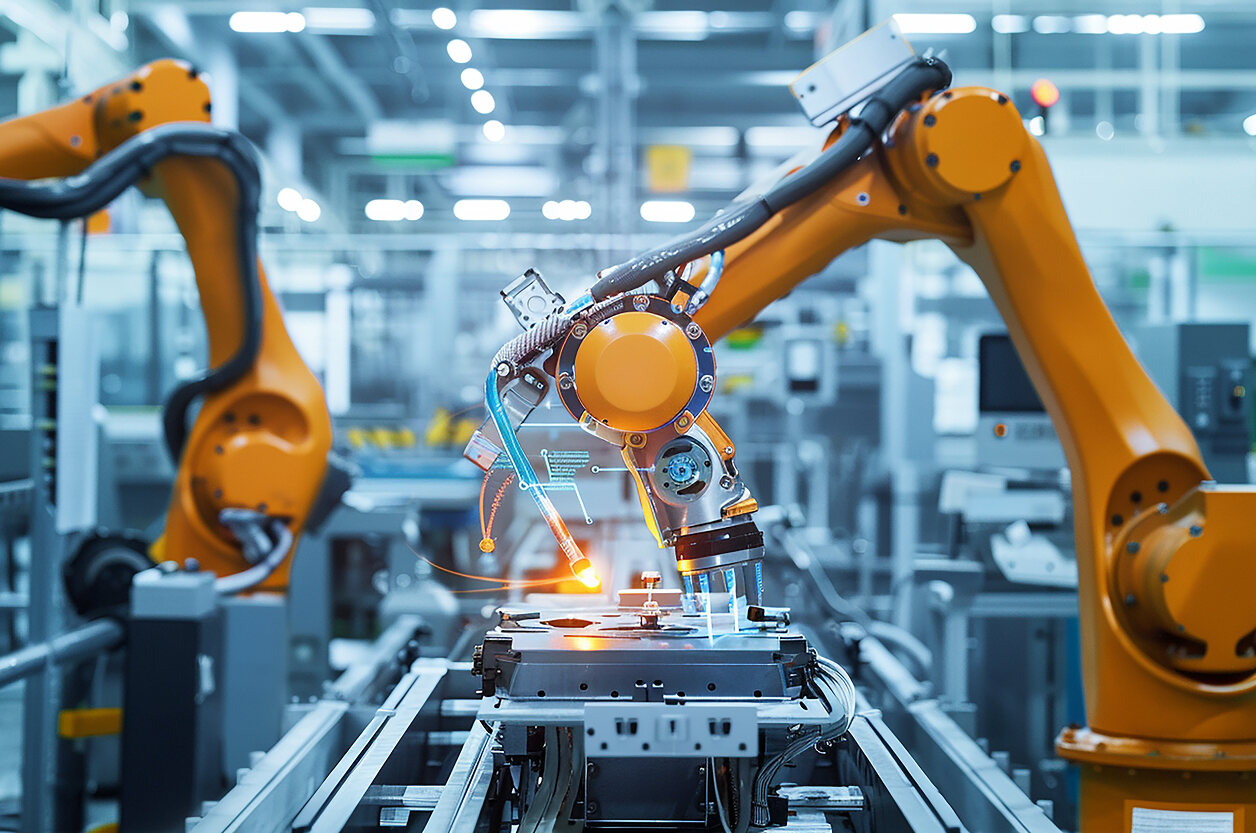

Consider a high-speed production line where micro-defects appear unpredictably. An old sensor would simply report raw data and rely on a central controller or cloud analytics platform to interpret it. Sensors 2.0 can detect anomalies immediately and respond within milliseconds, enabling real-time adjustments that would be impossible with centralized processing alone. The presence of embedded AI, DSP units and advanced firmware in modern sensors allows them to compress, filter, label and sometimes even classify data before anyone else ever sees it.

Why higher fidelity changes the entire industrial feedback loop

Resolution is no longer just a matter of how precisely a sensor measures a physical value. Today, fidelity includes temporal resolution, spectral insight, multi-axis awareness, environmental compensation and self-calibration. Sensors 2.0 often combine multiple sensing modalities into one device: vibration with acoustics, pressure with thermal mapping, optical signatures with motion analysis.

This expanded fidelity allows industrial systems to identify patterns that were previously invisible. Instead of detecting only the end result of a problem, Sensors 2.0 detect its onset. Instead of observing a process indirectly, they observe it from multiple angles at once. The factory becomes more transparent, not through additional hardware but through smarter hardware.

How next-generation sensors redefine predictive maintenance

Predictive maintenance traditionally relied on periodic checks, threshold alerts and historical analysis. But factories increasingly demand continuous prediction rather than scheduled checks. Older sensors typically provide too little data or too much noise to support reliable forecasting. Sensors 2.0 change this dynamic by producing data streams that are stable, high-resolution and semantically rich.

This enables maintenance systems to forecast not just whether a component will fail, but how it will fail, under what conditions, and how behaviour is changing over time. It reduces false positives, prevents unnecessary shutdowns and extends the useful life of machinery. In industries where equipment is extremely expensive, or downtime is catastrophic, this shift in sensing capability becomes a strategic advantage.

Why connectivity and interoperability matter more than ever

Modern factories operate as ecosystems rather than isolated machines. Sensors must communicate not only with PLCs but with gateways, digital twins, analytics engines and cloud platforms. Sensors 2.0 are built with this in mind. They support flexible networking models, multiple protocols and cybersecurity mechanisms that older devices lack.

This connectivity transforms industrial sensing from a point solution into a network effect. When sensors collaborate, they generate higher-order insights. When machines share data, production lines coordinate more efficiently. Connectivity is not merely a technical feature; it is an operational multiplier that changes how factories perceive themselves and their processes.

A concrete example of Sensors 2.0 in the real world is our electromagnetic flowmeter design for a South African electrical equipment manufacturer. Instead of relying on mechanical or weighing methods — or losing critical signal detail through traditional analogue processing — the device uses an STM32F7 with a high-performance DSP coprocessor to extract richer information from the measurement chain, including contaminant detection and more stable flow control at higher filling speeds. Just as importantly, it behaves like an industrial node rather than a passive probe: built-in interfaces and protocols enable it to plug into modern automation environments, share diagnostics, and support scalable production lines. This is the shift in miniature — measurement plus interpretation, delivered directly at the edge.

How Sensors 2.0 enable AI inside industrial systems

AI-driven automation depends on data that is both granular and reliable. Legacy sensors rarely meet these requirements, producing low-resolution or inconsistent signals that force engineers to spend enormous time cleaning and aligning data. Sensors 2.0 bypass these issues by producing well-structured, high-quality signals optimised for machine learning pipelines. Some even integrate lightweight AI models directly into the sensor firmware, allowing real-time classification or detection at the source.

This leads to faster training cycles, simpler model deployment and more accurate predictions. It also enables closed-loop control based on AI output rather than static rules. Factories that adopt Sensors 2.0 often discover they can use AI in places previously thought impractical: micro-assembly, precision machining, dynamic calibration or adaptive robotics.

Why environmental awareness changes sensor behaviour

Next-generation sensors do not simply measure the world; they compensate for it. Temperature drifts, mechanical stress, humidity, electromagnetic interference and vibration previously caused measurement noise or behaviour drift. Sensors 2.0 use advanced calibration routines, internal diagnostics and environmental modelling to correct for these influences.

This makes them far more stable across real-world conditions. Industrial systems benefit from fewer errors, less downtime, more confidence in measurement chains and reduced recalibration overhead. In harsh environments—such as metal processing, food production, chemical plants or outdoor infrastructure—environmental robustness often determines whether digital initiatives succeed.

The rise of multi-sensor fusion inside industrial environments

Industrial processes are rarely explained by a single variable. A vibration spike may indicate a mechanical issue, but only when evaluated together with temperature, torque, acoustic signatures or load can the system classify the problem accurately. Multi-sensor fusion has long existed at the automation level, but Sensors 2.0 bring it directly into the sensing hardware itself.

Devices capable of combining signals internally improve accuracy and reduce the need for external computation. They deliver more stable insights and support advanced applications such as digital twins, condition-based monitoring and high-speed anomaly detection. Sensor fusion is becoming a baseline expectation rather than an advanced feature.

How Sensors 2.0 transform safety, compliance and certification

Safety systems rely on strict reaction times and guaranteed behaviour. Old sensors, while reliable, often lack the diagnostics and self-monitoring capabilities needed for modern safety architectures. New sensors embed continuous health checks, redundancy logic and better fault reporting. They help factories meet higher certification levels and comply with evolving safety standards.

In environments where human-machine collaboration is increasing, such as cobot-enabled production lines, high-quality sensing becomes central to preventing accidents and maintaining safe operational envelopes.

Promwad’s perspective on designing systems around Sensors 2.0

As a company working with industrial automation, embedded electronics and edge intelligence, Promwad sees Sensors 2.0 as a fundamental building block of next-generation operational systems. Designing around modern sensors means rethinking data flows, redesigning control loops and aligning edge-to-cloud platforms with the realities of physical processes. Our work shows that factories benefit most when sensors are not treated as isolated devices but as intelligent participants in a distributed decision-making network. This requires both engineering depth and UX-level thinking, because clarity, predictability and operational transparency matter just as much as raw performance.

Where the future of industrial systems is heading with next-generation sensors

As Sensors 2.0 become more ubiquitous, factories will evolve toward predictive, adaptive and self-optimising environments. Production lines will increasingly adjust themselves in real time. Maintenance cycles will become more personalised and less disruptive. Digital twins will become more accurate because they will be fed by richer, higher-quality data. AI will expand into micro-decisions across the plant, supported by sensors capable of delivering meaningful signals rather than generic metrics.

The industry is moving toward a world where sensing is not just measurement but awareness, and where awareness shapes every level of industrial behaviour—from machine control to corporate planning. Factories that embrace these new sensing capabilities will gain clearer visibility into their processes, stronger resilience, more efficient operations and an unparalleled ability to adapt.

AI Overview

Next-generation sensors reshape industrial systems through richer data and embedded intelligence. Key Applications: predictive maintenance, adaptive control, digital twins, quality analytics and robotic precision. Benefits: higher fidelity, reduced latency, increased reliability, improved situational awareness and better AI performance. Challenges: legacy integration, calibration complexity, cybersecurity, protocol diversity and scaling across environments. Outlook: Sensors 2.0 become the foundation for autonomous, self-optimising industrial operations. Related Terms: edge sensing, smart devices, sensor fusion, industrial AI, adaptive automation.

Our Case Studies