Electromagnetic Flow Meter Sensor Development

Project in Nutshell: commissioned by a South African electrical equipment manufacturer, we designed an electromagnetic flow meter to replace mechanical and weighing technologies that were expensive and difficult to scale.

The new solution ensured accurate measurements, contaminant detection, and improved manufacturing efficiency. It is based on the STM32F7 MCU powered by a high-performance DSP coprocessor with the speed of 400 million instructions per second.

Client & Challenge

A South African equipment manufacturer intended to create an electronic device to measure the amount of liquid, detect contaminants in the fluid and ensure the correct density/viscosity for specific applications.

The traditional analogue approach does not easily extract such information, primarily due to the loss of sensor data during synchronous demodulation.

Our client also needed to improve the productivity and efficiency of their manufacturing processes. As production scale and filling speeds increase, there is a need for faster and more accurate flow control.

Solution

A South African equipment manufacturer intended to create an electronic device to measure the amount of liquid, detect contaminants in the fluid and ensure the correct density/viscosity for specific applications.

The traditional mechanical or weight method of determining the exact amount of liquid in batching or manufacturing processes is expensive and hard to scale. The analogue approach also does not easily extract necessary information, primarily due to the loss of sensor data during synchronous demodulation.

Our client needed to improve the productivity and efficiency of their manufacturing processes. For example, in liquid dosing/filling systems, adding more filling units is standard practice. As production scale and filling speeds increase, there is a need for faster and more accurate flow control.

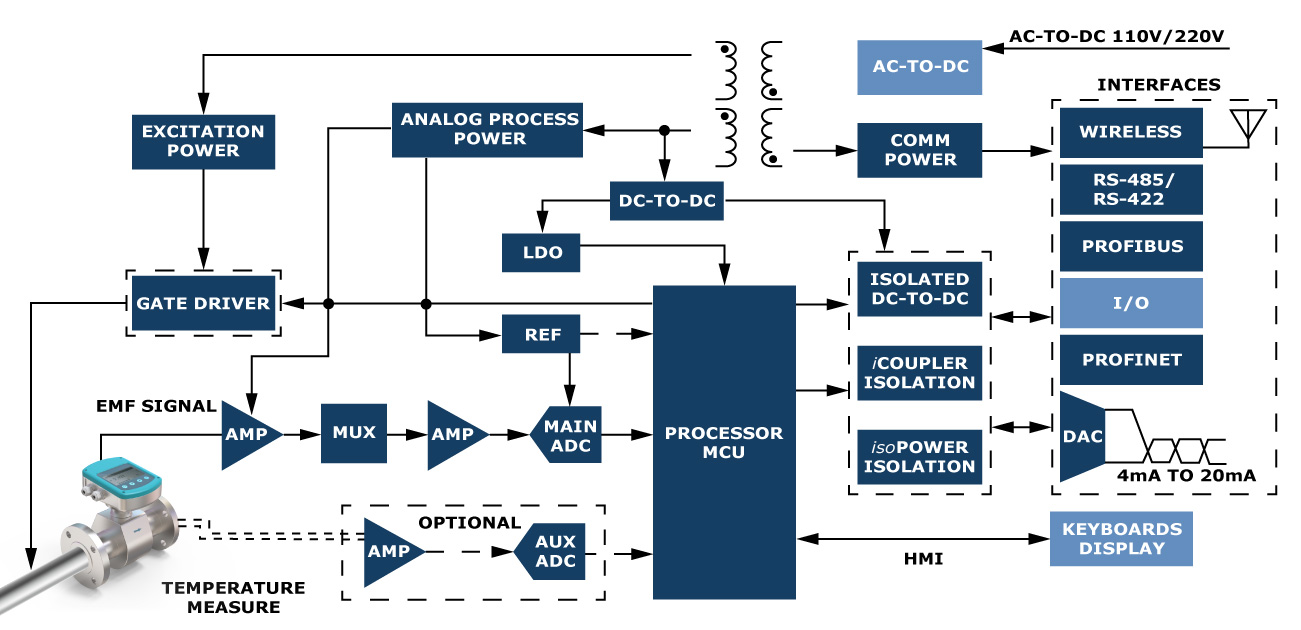

Work scheme of electromagnetic flow meter

The on-chip peripherals make it an embedded sensor platform with industrial communication interfaces:

- The microcontroller implements various functions, such as Ethernet, SPI, UART, I2C, and pulsed output communications.

- 35 GPIOs (general purpose input/output pins) dedicated to hardware control and logic input/output, utilised for tasks such as LCD control, keypad input, alarms, and diagnostics.

- SRAM memory is storage for filter coefficients, RS-485, HART, PROFINET and SPI data communication, user data, machine state data, and internal status flags.

- The STM32F7 microcontroller with DSP coprocessor 2 MB on-chip flash memory is utilised to store program data, filter coefficients, and calibration parameters.

Technologies: C, C++, PROFINET, HART, Modbus RTU, Yaffs 2, LVGL, DSP mathematics (CMSIS DSP), bootloader (mcuboot), Embedded Proto, USB CDC/ USB MSC, timers, Wi-Fi, qbs

Business Value

Our client will integrate the ready-made electromagnetic flow meter into their product line, to offer a seamless integration solution for their diverse customer base, including contractors, electricians, and system integrators. With this strategic move, they will enhance the functionality and flexibility of their customers' flow meter setups, which helps reduce the overall cost of the solution.