Designing for Longevity: How to Build Electronics That Last

Why Sustainability Is No Longer Optional in Hardware Design

The electronics industry is facing a defining moment. Devices are getting smaller, smarter, and more interconnected — yet their lifespans remain painfully short.

From smartphones to industrial controllers, products are being replaced faster than ever, leaving behind massive amounts of electronic waste.

Governments, consumers, and enterprise buyers are all pushing for change. Regulations such as the EU Green Deal, Ecodesign Directive, and the upcoming Right to Repair laws are redefining how hardware must be designed, manufactured, and recycled.

Sustainability in hardware design is no longer a marketing buzzword — it’s becoming an engineering requirement.

To stay competitive, manufacturers must create eco-friendly, long-life electronics that combine performance, durability, and circular economy principles.

The Environmental Cost of Modern Electronics

Electronics production accounts for a growing share of global CO₂ emissions, largely due to raw material extraction, energy-intensive manufacturing, and waste disposal.

A single smartphone involves over 60 different materials, including rare earth elements like neodymium and dysprosium — most of which are mined under harsh environmental and social conditions.

Moreover, e-waste is the fastest-growing waste stream in the world, surpassing 50 million tons annually. Only a small fraction is recycled efficiently, while the rest ends up in landfills or exported to developing regions.

Sustainable hardware design tackles this problem at its source — by reducing resource intensity, prolonging product life, and enabling circular reuse of components.

What Sustainable Hardware Design Really Means

At its core, sustainable design aims to minimize the total environmental impact of a product throughout its entire lifecycle — from concept to disposal.

This involves five key pillars:

- Material efficiency: using recyclable, renewable, and non-toxic materials.

- Energy efficiency: reducing power consumption during operation and standby.

- Design for longevity: extending lifespan through durable construction and modular upgrades.

- Repairability and recyclability: simplifying maintenance, component replacement, and end-of-life disassembly.

- Responsible manufacturing: reducing carbon footprint and ensuring ethical sourcing in the supply chain.

By integrating these principles early in the design process, companies can drastically improve their sustainability profile without sacrificing performance or profitability.

Design for Longevity: Fighting Planned Obsolescence

Modern devices often fail long before their technology becomes obsolete. Batteries degrade, connectors wear out, and components go out of stock.

A sustainable approach starts by designing for longevity and repairability.

That means:

– Choosing components with extended availability and clear end-of-life (EOL) policies.

– Using standardized connectors and mechanical parts.

– Avoiding unnecessary sealing or gluing that prevents repair.

– Supporting firmware and software updates for years after release.

Long-life hardware not only benefits the planet but also improves brand reputation and customer loyalty — especially in industrial and professional markets, where reliability equals trust.

Material Selection: Beyond Recyclability

Selecting the right materials is one of the biggest levers for sustainability.

Eco-friendly materials are not just about recyclability — they’re about reducing toxicity and embodied energy.

For example:

– Replacing PVC and brominated flame retardants with halogen-free alternatives.

– Using bio-based or recycled plastics in enclosures.

– Choosing aluminum over steel for lighter, more recyclable designs.

– Considering ceramic or biopolymer substrates for PCBs in specialized cases.

Material databases and sustainability rating systems are now widely available, allowing engineers to make informed trade-offs during component selection.

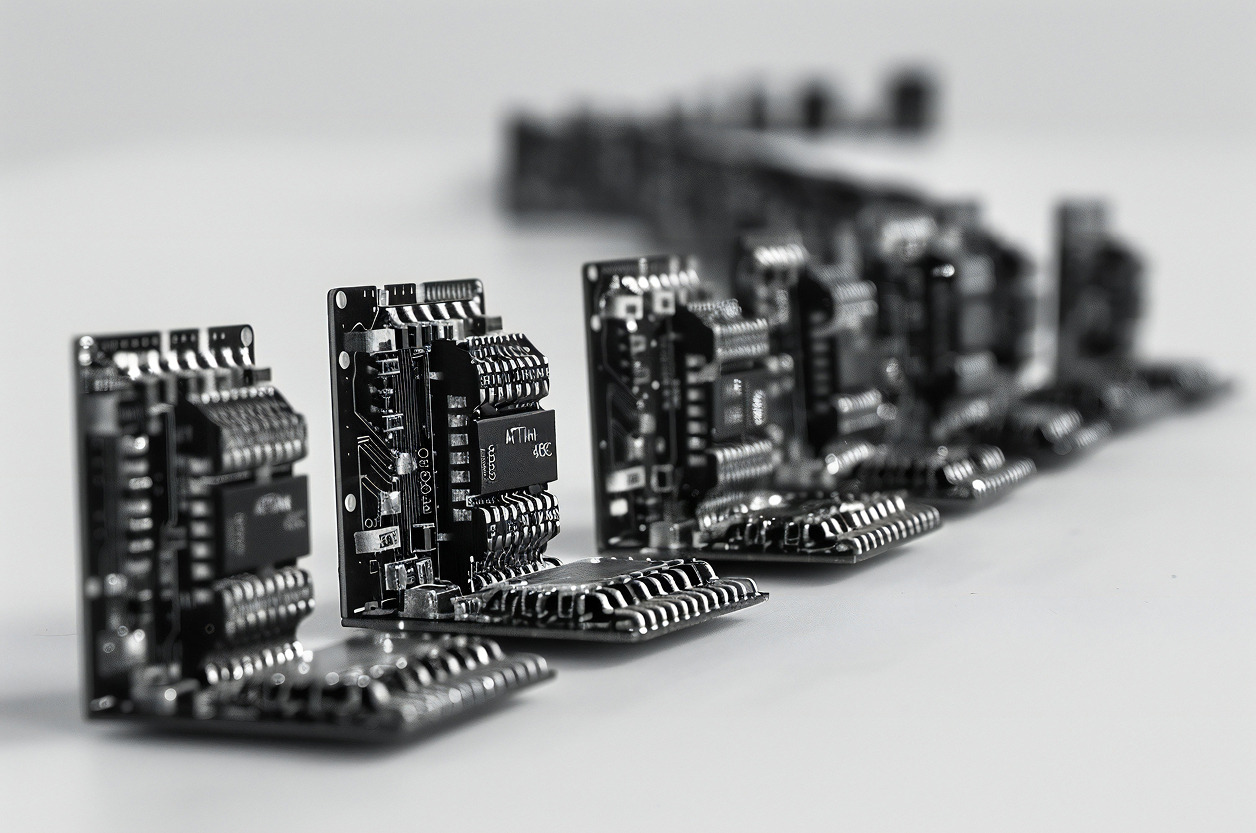

Modularity and Design for Disassembly

A truly sustainable product should be easy to upgrade, repair, and disassemble.

Modular design allows replacing only what’s necessary — for example, upgrading a sensor board or wireless module instead of discarding the entire device.

This principle is already being adopted in sectors such as industrial IoT, where systems are expected to operate for decades. Modular architectures also simplify end-of-life recycling, since components and materials can be separated efficiently.

Design for disassembly means avoiding permanent adhesives, labeling recyclable parts, and providing service documentation.

It’s a small design decision that significantly increases the reuse potential of electronics.

Power Efficiency and Smart Energy Management

Energy efficiency is a cornerstone of sustainability.

For battery-powered devices, lower energy consumption directly extends product life; for mains-powered equipment, it reduces operational carbon emissions.

Sustainable designs leverage:

– Low-power microcontrollers and SoCs with advanced sleep modes.

– Dynamic power scaling based on workload.

– Efficient power converters and regulators.

– Adaptive firmware algorithms to optimize runtime.

In industrial environments, these techniques can reduce total power draw by 20–40%, adding measurable value for operators seeking energy certification or green facility compliance.

Circular Economy in Electronics

The circular economy redefines how we think about product value.

Instead of the linear “take-make-dispose” model, it emphasizes keeping materials and components in circulation for as long as possible.

This involves strategies like:

– Refurbishment: repairing and reselling returned devices.

– Remanufacturing: restoring components to original quality.

– Recycling: recovering metals and plastics for reuse.

– Material tracking: using digital IDs (like Digital Product Passports) to record component origins and lifecycle.

Forward-looking companies are already integrating these ideas into their logistics systems — turning waste into a resource stream and reducing dependency on raw material extraction.

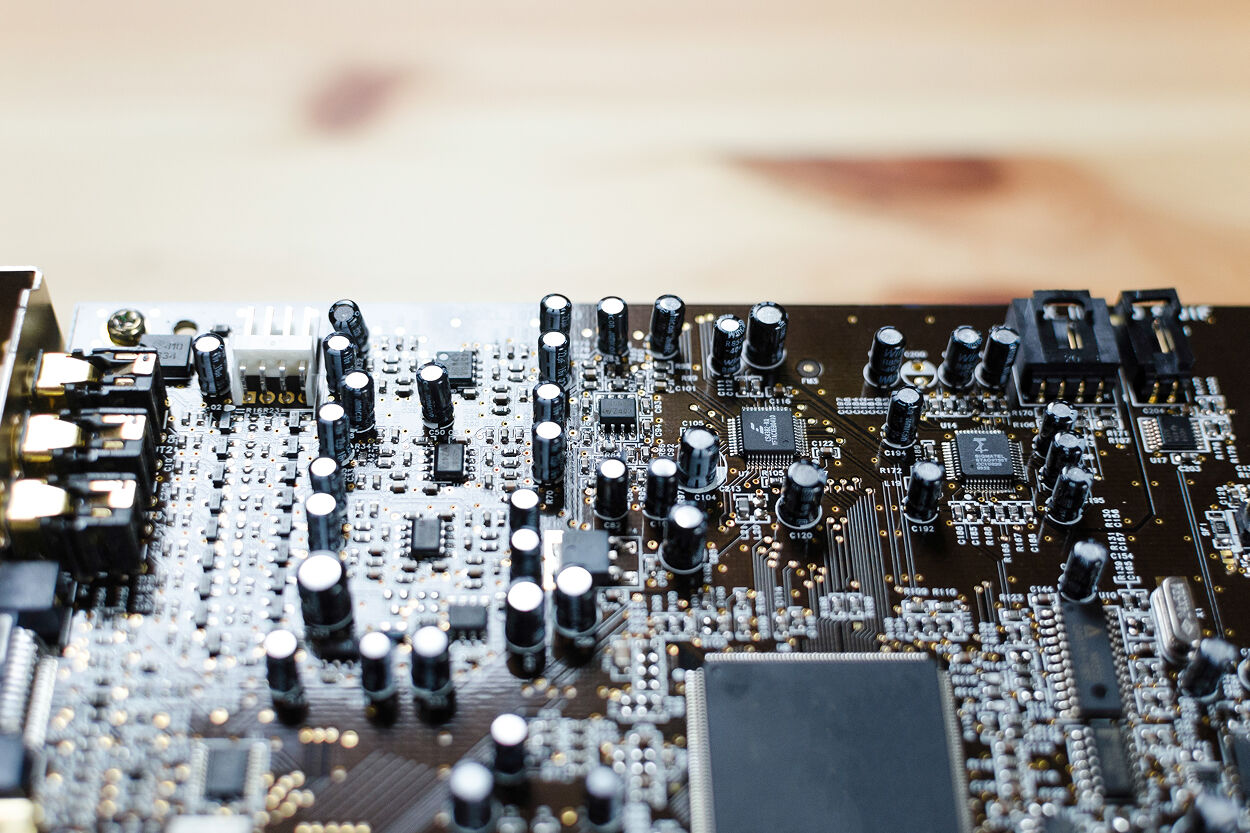

Sustainable Manufacturing Practices

A green product can’t come from a dirty factory.

Sustainability extends to how and where devices are produced.

Key improvements include:

– Using renewable energy for production facilities.

– Minimizing chemical solvents and water usage during PCB fabrication.

– Optimizing logistics to reduce transportation emissions.

– Implementing waste heat recovery and closed-loop cooling systems.

Suppliers and EMS partners are increasingly rated on sustainability metrics. Choosing manufacturing partners with ISO 14001 or equivalent certifications is becoming a standard practice in responsible engineering.

Lifecycle Assessment (LCA): Measuring What Matters

To design sustainably, teams must measure environmental impact accurately.

Lifecycle Assessment (LCA) tools quantify the total energy use, emissions, and resource depletion of a product across its full lifecycle.

This data helps engineers make fact-based design decisions and communicate them transparently to clients and regulators.

A good LCA goes beyond components — it includes packaging, transportation, and end-of-life management. Combined with SBOM-style transparency, it paints a complete picture of the product’s sustainability footprint.

Durability Testing and Predictive Maintenance

Designing long-life electronics means anticipating failure before it happens.

Accelerated aging, vibration, and thermal cycling tests validate that hardware will survive in real-world conditions.

Adding sensors for self-diagnostics and predictive maintenance extends operational lifespan even further.

For example, a motor controller that monitors its own temperature and power cycles can alert the system before a critical failure occurs — preventing downtime and avoiding premature disposal.

Such approaches turn sustainability into a functional advantage.

Balancing Performance and Sustainability

A common misconception is that sustainable design compromises performance.

In reality, the two can reinforce each other.

Optimized energy management improves efficiency.

Modularity enhances flexibility and scalability.

Material reuse lowers costs over time.

The challenge is balancing engineering priorities: performance, cost, weight, and environmental impact. Modern simulation and material modeling tools help find this equilibrium early in the design phase.

Regulatory Momentum and Industry Standards

Sustainability is rapidly becoming codified into law.

The Ecodesign Directive, RoHS, REACH, and the Circular Electronics Partnership (CEP) framework all establish requirements for durability, recyclability, and responsible sourcing.

The upcoming Right to Repair laws across Europe and the US will further force manufacturers to make repairable designs and provide spare parts for years.

Meanwhile, new green PCB initiatives and low-carbon semiconductor manufacturing programs are gaining traction across Asia and the EU, signaling a global movement toward climate-conscious electronics.

Real-World Examples

Fairphone pioneered modular smartphones with replaceable cameras and batteries — proving sustainability can coexist with innovation.

Dell and HP have adopted closed-loop recycling, using recovered plastics from old devices to manufacture new ones.

Siemens and Schneider Electric now integrate lifecycle analytics and circularity metrics into their industrial hardware roadmaps.

These examples show a shift from isolated green projects to integrated sustainability strategies across the product portfolio.

The Business Case for Sustainable Design

Sustainability isn’t just a compliance burden — it’s a growth opportunity.

– Lower total cost of ownership (TCO): durable devices require fewer replacements and service calls.

– Brand differentiation: eco-conscious products appeal to modern consumers and B2B clients.

– Investor appeal: sustainability is now a core ESG criterion for funding and partnerships.

– Regulatory resilience: products designed for green standards stay ahead of evolving laws.

Companies that embed sustainability into engineering culture gain both ethical and economic advantages — a rare alignment of business and responsibility.

The Role of Engineers and Product Owners

True sustainability starts with design decisions.

Every choice — from the processor to the enclosure material — influences the device’s footprint for years to come.

Product owners must encourage cross-disciplinary collaboration:

– Mechanical engineers optimizing thermal design to reduce fans.

– PCB designers choosing low-halogen substrates.

– Firmware developers managing power intelligently.

– Industrial designers simplifying repair and recycling.

Together, these decisions create a tangible impact far beyond compliance metrics.

Toward a New Definition of Innovation

Innovation in hardware used to mean faster, smaller, cheaper.

The new frontier adds a fourth dimension — responsibility.

Designing for sustainability doesn’t slow progress; it defines the next generation of it.

As industries move toward net-zero goals, products that last longer, consume less, and waste nothing will set the new benchmark for engineering excellence.

Promwad’s engineering philosophy already reflects this — from concept to mass production, we help clients create electronics that are both advanced and sustainable.

AI Overview

Key Applications: eco-friendly device design, low-power embedded systems, modular and repairable hardware, circular manufacturing, and lifecycle assessment.

Benefits: longer product lifespan, reduced environmental footprint, improved brand value, and compliance with global green regulations.

Challenges: balancing cost and sustainability, sourcing eco-materials, integrating circular practices into design workflows, and maintaining performance efficiency.

Outlook: sustainable hardware design is becoming the new standard in electronics, driven by regulation and consumer awareness. Companies that master long-life, repairable, and efficient designs will lead the next wave of responsible innovation.

Related Terms: circular economy, lifecycle assessment, green electronics, modular hardware, energy-efficient design, eco-certification.

Our Case Studies