Know Weeks Ahead When Your Ventilation System Is About to Fail

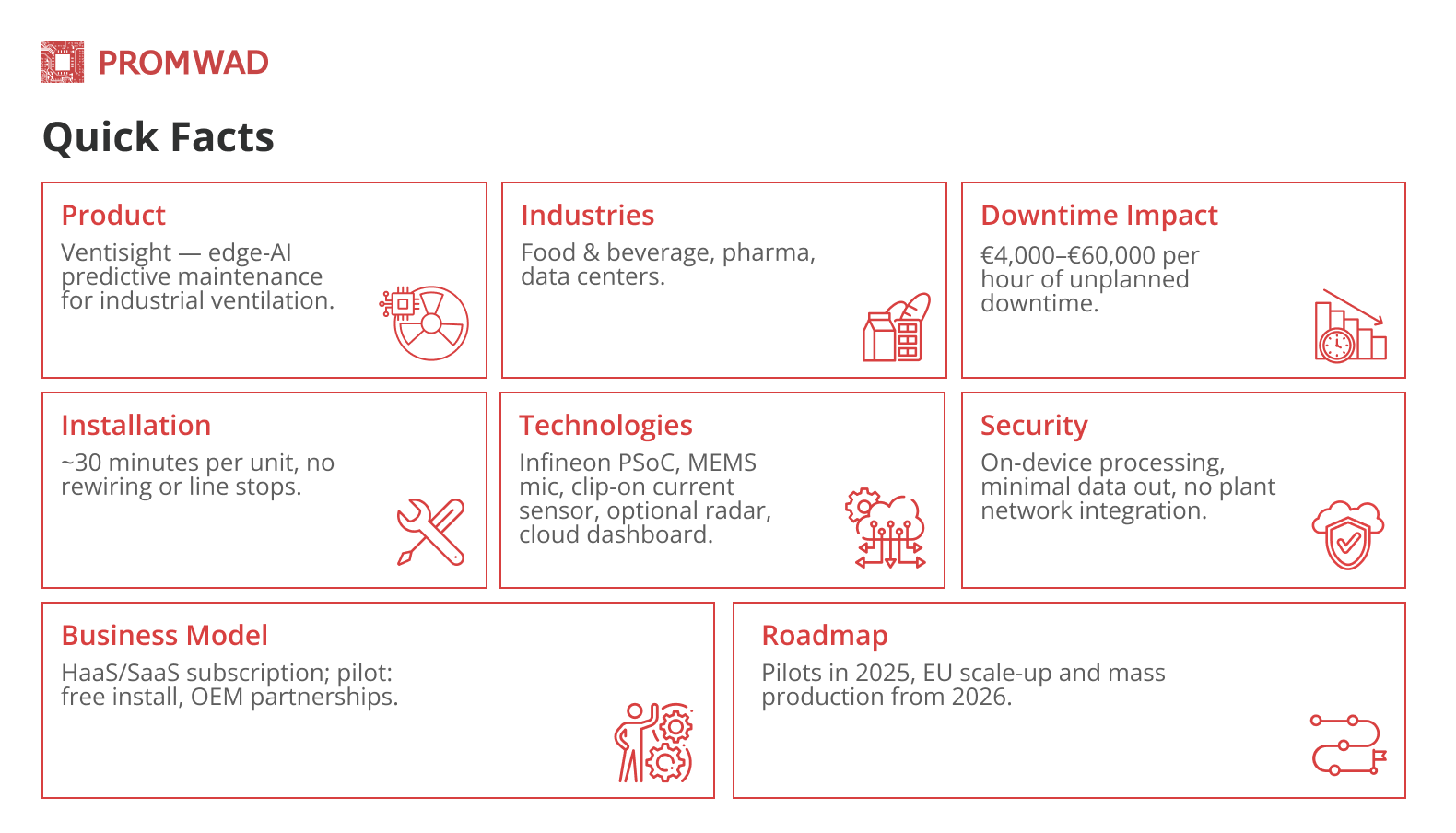

Project in a Nutshell: Ventisight is a compact edge-AI module with a multi-sensor kit that we developed for industrial manufacturers, pharma plants and data centres to prevent ventilation fan and motor failures before they cause downtime. It works with existing equipment, installs in approximately 30 minutes without requiring rewiring or interrupting production, and provides health insights on a separate dashboard, avoiding the security headaches of plant network integration. Concept and design were initiated in 2024, with pilots run in 2025 and planned scale-up to mass production and commercial deployments in 2026.

Challenge

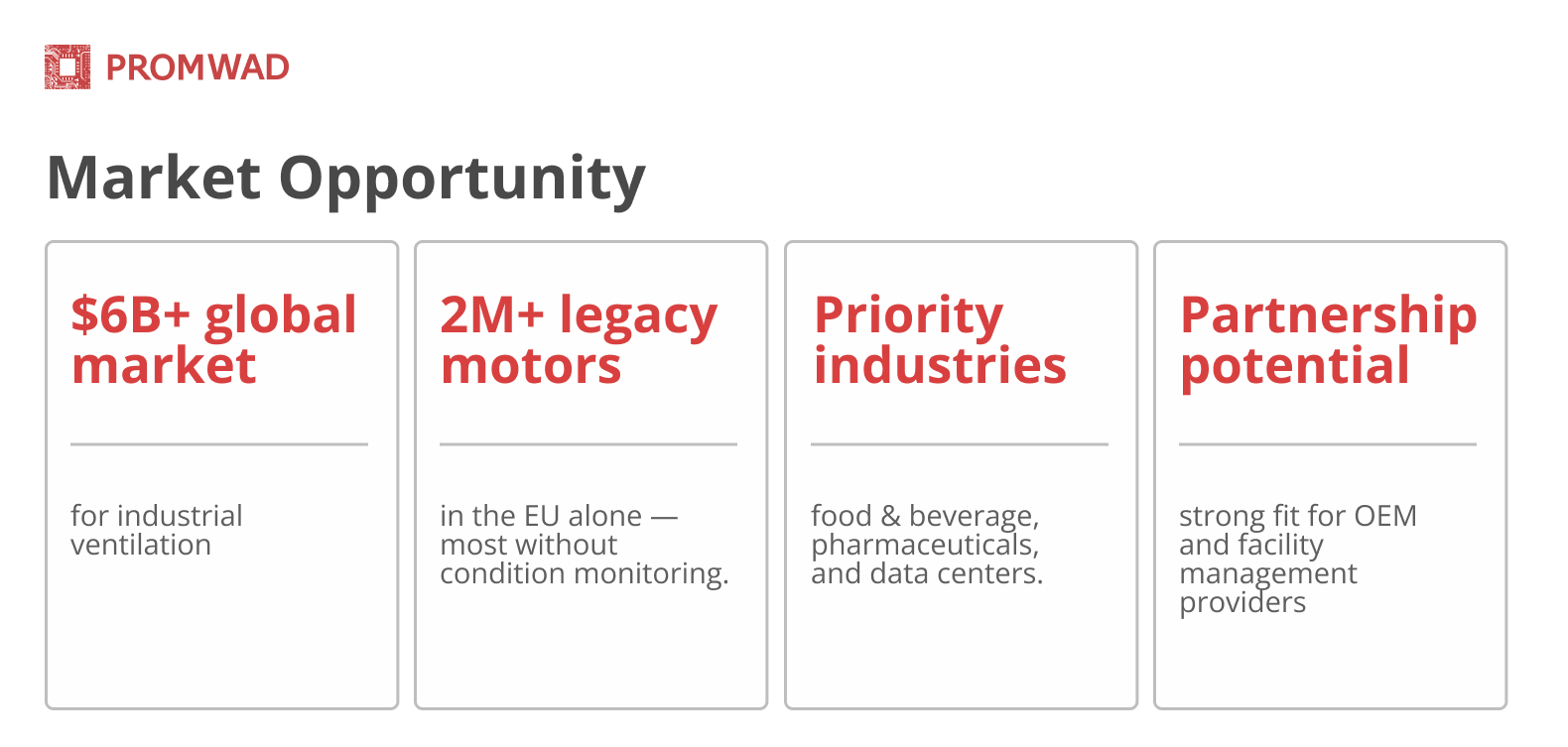

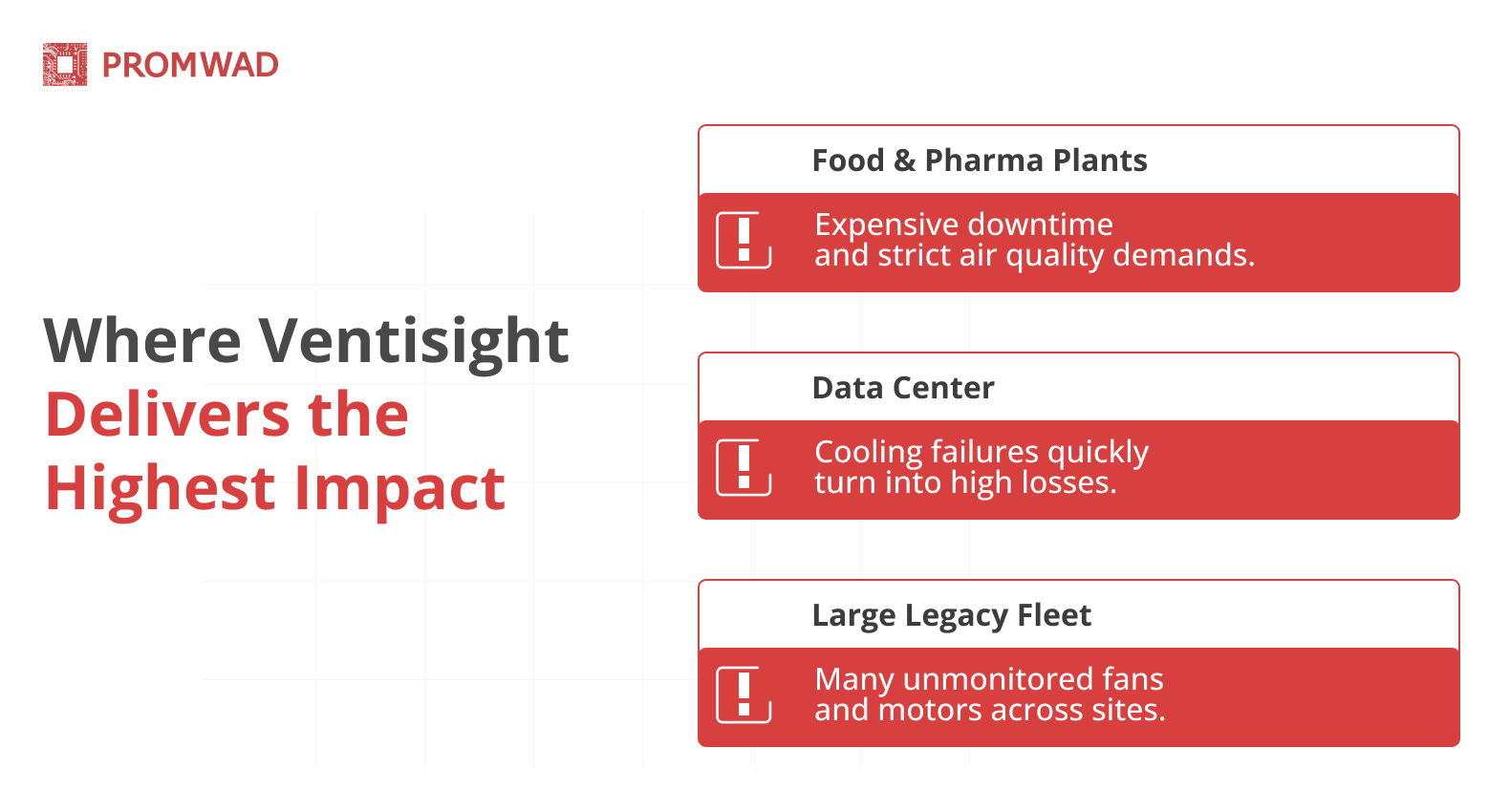

In high-throughput manufacturing and data centres, unplanned fan or motor failures in ventilation quickly turn into a single point of failure: production stops, product quality is at risk, safety conditions degrade, and each hour of downtime can cost €4,000–€60,000 in lost output and emergency repairs.

Maintenance teams often work with limited visibility, relying on generic alarms and time-based service intervals. However, advanced monitoring solutions are costly, complex to roll out at scale, and raise concerns about network security. As a result, ventilation is rarely monitored condition-based, and organisations carry a significant risk of unexpected outages. Ventisight addresses this gap by making the early degradation of fans and motors visible, without requiring heavy IT integration or operational disruption.

Business Value & Where It Matters Most

Ventisight helps you move from reacting to ventilation failures to actively managing them as a reliable part of your production infrastructure. Its impact shows up in some key areas:

- Reduced unplanned downtime. Early detection of emerging faults lowers the risk of line stoppages and critical equipment failures.

- Lower OPEX. Planned, condition-based maintenance is more cost-effective than emergency repairs and last-minute parts procurement.

- Stable quality and safer environment. Fewer failure modes and abnormal operating conditions help maintain a clean and safe production environment.

- Stronger compliance. Proactive control of ventilation reduces the likelihood of regulatory incidents, inspection issues, and fines.

- Actionable visibility for management, a clear dashboard with health indicators and events, supports data-driven decisions about maintenance and asset strategy.

Solution

Ventisight is a compact edge-AI module with a multi-sensor kit.

The device is mounted directly on the ventilation unit and listens to acoustic, electrical and motion patterns. Embedded AI models running on an Infineon PSoC chip analyse these signals on the device itself and detect early signs of degradation, providing clear alerts and insights to a secure dashboard.

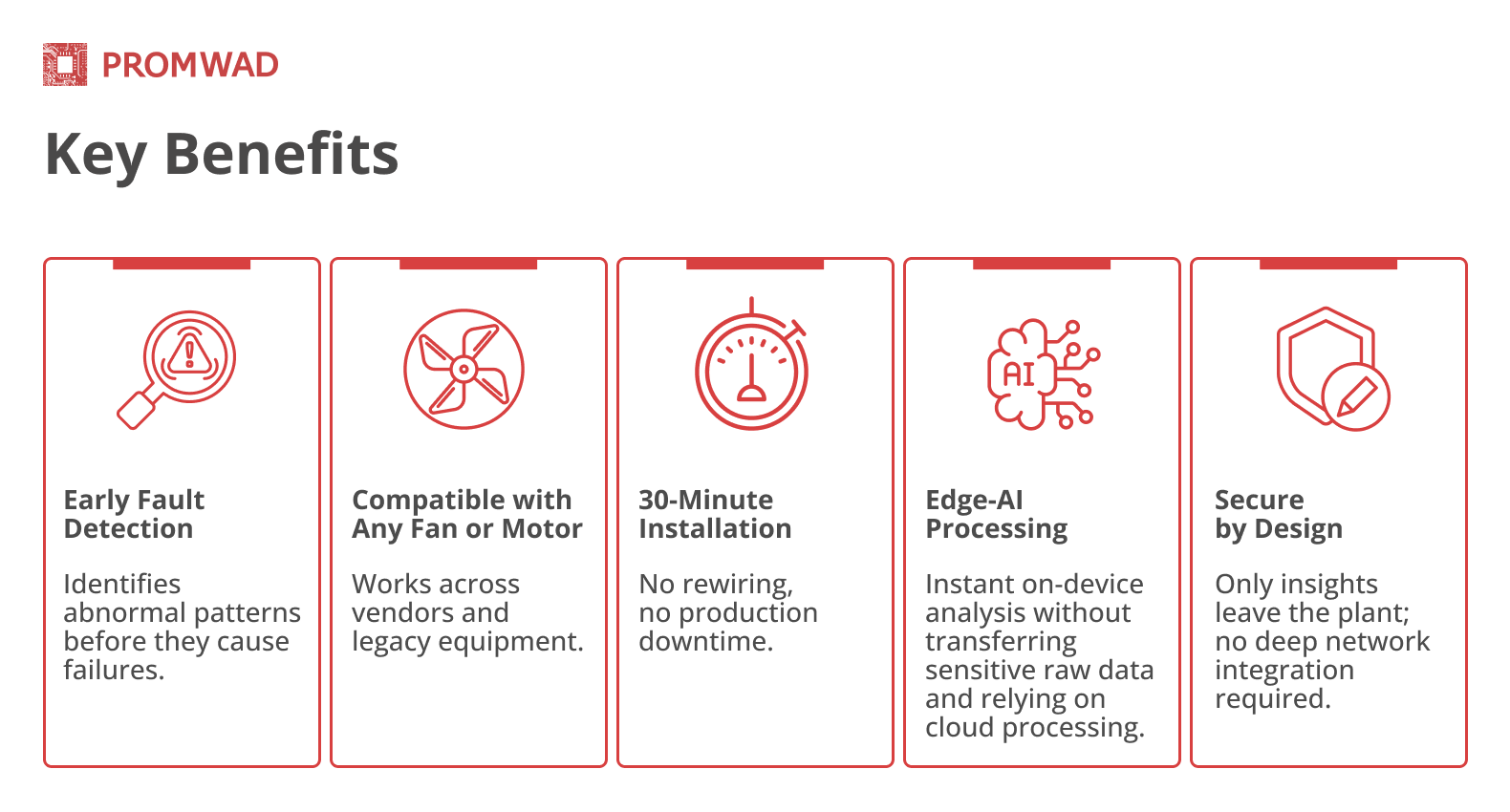

Key properties of the solution:

How It Works

Ventisight utilises a set of compact sensors and on-device AI to analyse fan and motor behaviour in real-time, delivering early warnings without relying on cloud processing.

- Sensors capture the fan’s operating condition.

- A MEMS microphone detects vibration and noise patterns that reveal bearing wear, imbalance, or resonance.

- A clip-on current sensor tracks the motor’s electrical behaviour and detects overloads, asymmetry and abnormal start-up patterns.

- An optional radar sensor measures fan speed and confirms rotor movement.

- Edge-AI analyses the data on the device. The Infineon PSoC chip inside the module processes signals locally and uses embedded AI models to identify early signs of degradation before they escalate.

- Only insights go to the cloud dashboard. Ventisight sends compact health indicators and alerts rather than raw sensor data, keeping sensitive information inside the plant and simplifying integration.

- Alerts remain available even offline. Because analysis happens at the edge, Ventisight continues to provide local alarms and on-site status updates even if the internet connection is temporarily unavailable.

Why Promwad

We combine deep expertise in embedded systems, hardware design and on-device machine learning. Our team has long-standing experience building reliable edge solutions, optimising ML models for constrained devices, and designing robust electronics for industrial environments — the core capabilities that make Ventisight accurate, secure, and easy to deploy at scale.

We offer flexible engagement models tailored to how you operate and scale your maintenance strategy.

- Turnkey Pilot: installation on the selected units; prove the value in a real environment;

- HaaS/SaaS Subscription: ongoing monitoring, model updates and support per site or asset.

- OEM Partnerships: white-label integration, technology licensing.

More of What We Do for Industrial Automation

- HVAC Solutions: explore our portfolio of electronics design services for heating, ventilation, air conditioning (HVAC) and refrigeration equipment.

- Fire Alarm System Design: сheck out the project to develop a fire alarm system with enhanced safety features to improve the safety of facilities and personnel.

- Practical Solutions for Building Efficiency: learn about our research on KNX, BACnet and Matter building automation protocols for improving efficiency.