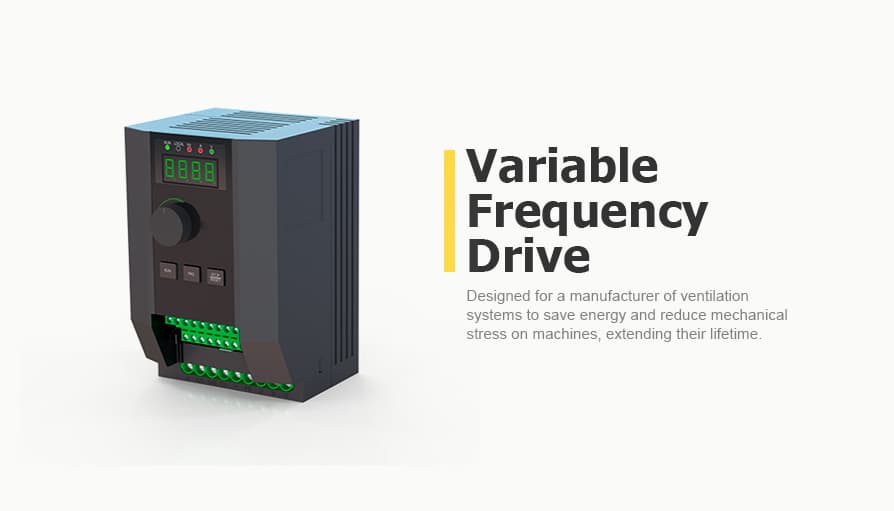

Variable Frequency Drive (VFD) for Ventilation System

Client

A large industrial company that manufactures ventilation systems.

Challenge

To design a variable frequency drive to be used in the new range of ventilation systems. The client wanted us to design hardware, develop software, and prepare everything necessary to make the first prototypes and launch mass production.

Solution

Promwad engineering team designed hardware and developed software for variable frequency drive with the following features:

- Scalar control (V/f)

- Vector control

- Field oriented control

- Direct torque control

- Sensorless field-oriented control

- Direct torque control with switch table

- Modbus TCP/IP (Ethernet)

- Modbus RTU (RS-485)

- 0-10V

- 4-20mA

- DI/DO functional purpose

- Safe torque off (STO)

- Galvanic isolation for the control board

- Current sensing

- Over-current protection

- Speed-sensing

- Temperature sensing

ACIM

- 230V/380V

Business Value

The client got the variable frequency drive to save energy, improve system efficiency and the working environment, convert power in hybridization applications, reduce mechanical stress on machines, extend their lifetime, and many more.