Structural Battery Composites: How Energy-Storing Materials Could Transform Electronics and Transportation

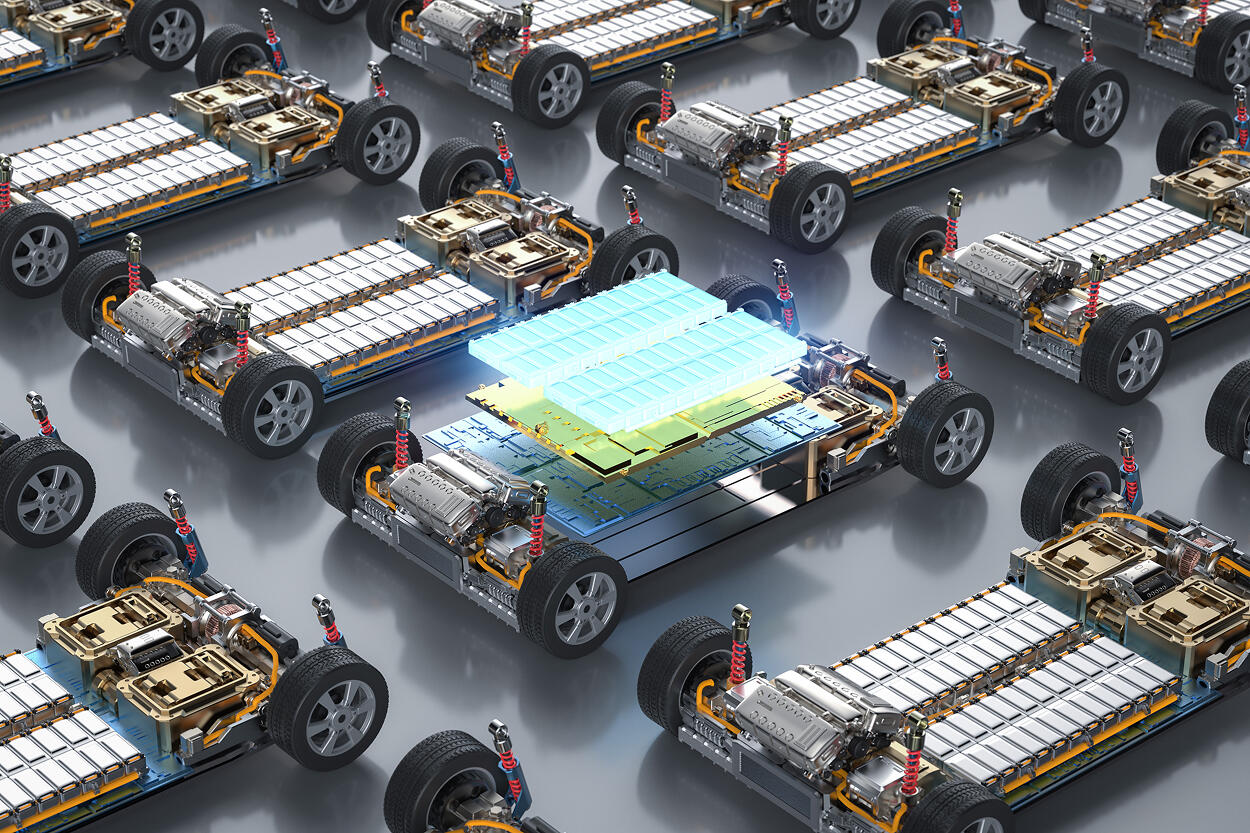

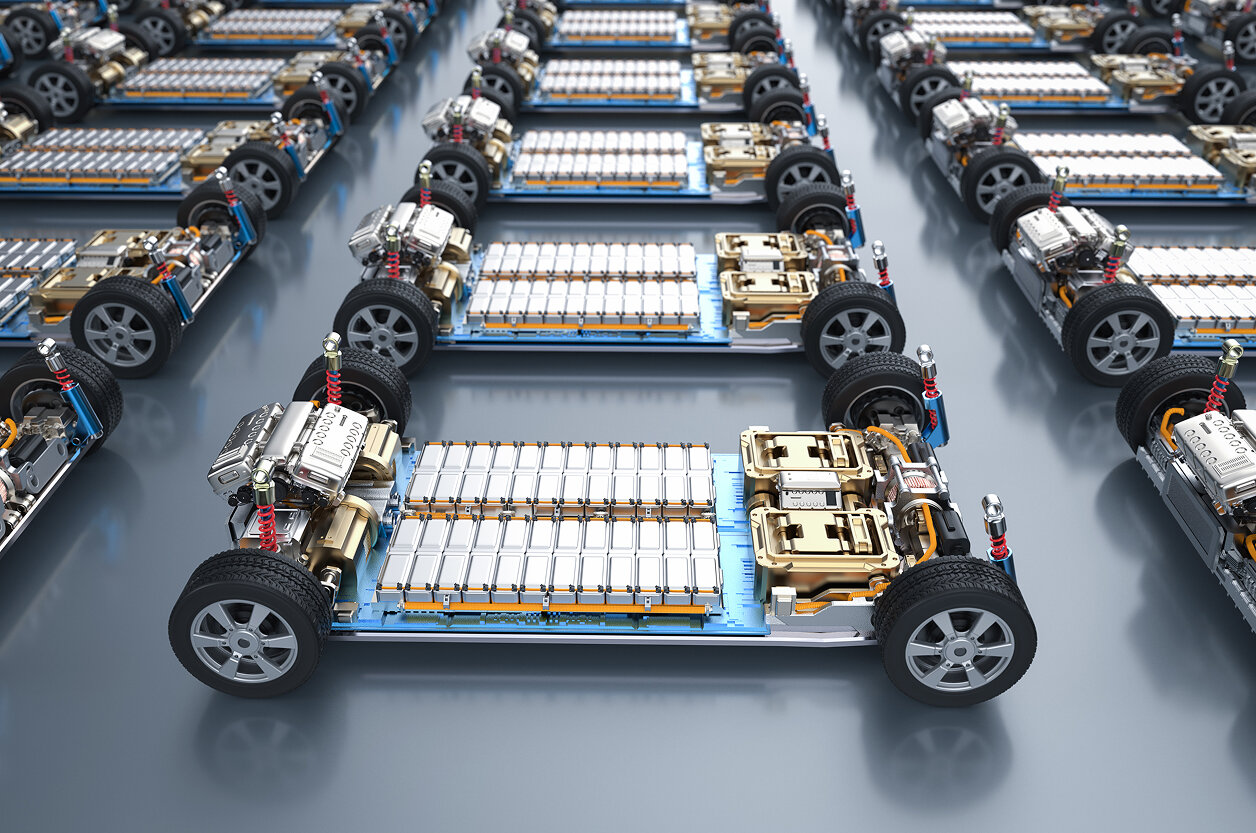

Imagine a material that doesn’t just hold your car or device together but also powers it. That’s the idea behind structural battery composites. They merge two functions that until now were kept separate: giving strength and storing energy. Instead of building a heavy car body and then filling it with even heavier battery packs, manufacturers could make the body itself a source of power.

For electric cars, airplanes, or even drones, this is a game-changer. Every gram saved on weight means longer range, more efficient use of energy, and in some cases even new design freedoms. No wonder organizations like the World Economic Forum call structural batteries one of the most promising technologies of this decade.

What are structural battery composites and why are they getting so much attention?

The secret lies in the choice of materials. Carbon fiber is the star here: strong enough to carry mechanical loads but also capable of acting as an electrode. Think of it as turning the “bones” of a vehicle into part of its “nervous system.” Between the carbon fiber layers sits a solid polymer electrolyte. It not only moves ions back and forth but also glues the whole structure together.

Researchers are working with two main approaches. One is to embed traditional battery cells into composite panels, so the panel itself becomes both structure and energy pack. The second, more radical approach is to use the fibers themselves as electrodes. In that case, the material is both skeleton and energy storage at once. This second method is harder to achieve but offers a far more elegant solution for the future.

How good are structural battery composites today?

They’re not perfect yet, but the progress is impressive. Current prototypes store between 30 and 90 watt-hours per kilogram. That’s still less than the 150 to 250 you’d get from a conventional lithium-ion cell, but here’s the twist: you don’t need to add extra housing or supporting parts, so the overall system can actually become lighter.

On the mechanical side, these composites are very strong. They reach stiffness levels similar to aluminum, with tensile strength exceeding 300 megapascals. Some recent lab results even showed energy densities above 60 watt-hours per kilogram combined with stiffness over 100 gigapascals — a remarkable balance of strength and storage. And they can cycle more than a thousand times without major degradation, which makes them promising for real-world applications.

Where could they make the biggest impact?

The most obvious candidate is the automotive industry. Electric cars today carry heavy battery packs that account for a large share of their total mass. If the roof, floor, or doors could serve as both body panels and batteries, cars would instantly become lighter and more efficient. Some studies suggest driving range could increase by as much as seventy percent.

In aerospace, the stakes are even higher. Every kilogram saved on an aircraft can reduce fuel consumption or extend flight time. For drones, structural batteries could mean significantly longer flights without adding bulky packs. For satellites, it could mean lighter launches and lower costs.

Consumer devices are another exciting field. Picture a laptop that weighs half as much because its casing doubles as the power source. Or a phone as thin as a credit card, where the back cover is also the battery. Robots, whether industrial or service-oriented, would also benefit — less clutter inside, stronger shells, and more space for sensors or tools.

While the vision of power-storing structures is compelling, the gap between promising prototypes and deployable products is where most real-world projects struggle. A closer look at the structural battery trade-offs shows that progress is less about headline energy density gains and more about system redesign, manufacturability, and certification realities. Understanding where these materials already work, and where they still introduce unacceptable risk or complexity, helps separate near-term opportunities from concepts that remain better suited to research environments than production lines.

What challenges remain before we see these in everyday products?

There are several. The first is energy density. Right now, structural batteries can’t compete with the top lithium-ion cells in terms of pure capacity. Engineers are optimistic, but reaching those higher numbers will take time and new materials.

Then there’s manufacturing. Producing a panel that is both a strong body part and a safe, reliable battery requires very precise processes. Any flaw could compromise either safety or performance. Scaling from lab samples to mass production is not trivial.

Safety regulations are another hurdle. If the battery is part of the structure, how do you test it in a crash? How do you ensure fire resistance or long-term durability? New certification frameworks will have to be created.

And finally, cost. Carbon fiber and advanced polymers are not cheap, and the manufacturing methods are still complex. For now, structural batteries may appear first in high-value markets such as aerospace or premium electric vehicles before trickling down to mass-market devices.

What is the outlook for the next decade?

Market analysts already see strong growth potential. The global market for structural battery composites could jump from just a few hundred million dollars in the mid-2020s to nearly a billion by 2032, with annual growth above twenty percent.

Research is accelerating too. Universities like Chalmers in Sweden are leading the charge, reporting record-breaking prototypes and building dedicated competence centers to train specialists in this field. The number of published studies has skyrocketed in recent years, showing that the scientific community is heavily invested in pushing this technology forward.

Looking ahead, the industry has clear milestones: achieving higher energy densities while maintaining stiffness, developing scalable manufacturing processes, and creating safety standards tailored to multifunctional materials. If these goals are met, structural batteries could become as common as carbon fiber is today.

Conclusion

Structural battery composites blur the line between power source and structure. They are not just about making batteries lighter; they are about rethinking the role of materials in engineering. While challenges in capacity, manufacturing, and regulation still stand in the way, the momentum is undeniable.

Over the next decade, we may see electric cars with battery doors, drones with power-storing wings, and gadgets powered by their own casings. When that happens, the phrase “the power is built in” will take on a whole new meaning.

Our Case Studies