IVI System for Luxury Cars: Architecture Design & BSP Development

Project in a Nutshell: We partnered with a supplier of IVI systems for luxury cars to transform their solution into a next-generation platform. To meet the ambitious timelines and deliver to multiple automotive OEMs in parallel, the client needed extra engineering capacity. Our dedicated team of embedded developers reinforced their internal development team, took ownership of specific functional blocks, and ensured on-time delivery without creating bottlenecks. We performed hardware testing, developed a robust BSP, and designed a scalable software architecture for Linux and QNX, all fully aligned with ASPICE standards.

Client & Challenge

Our client, a supplier of IVI systems for luxury cars, faced a resource gap during a critical development phase. Normally, their internal team handled all engineering tasks, but simultaneous projects for several OEMs put them at risk of missing deadlines. They needed a partner able to provide additional engineers who could seamlessly integrate into their processes, take over defined scopes of work, and guarantee ASPICE-compliant execution.

Promwad’s proven track record in complex automotive projects and our ability to build dedicated teams made us the right choice. By combining strong ASPICE processes with flexible resource scaling, we enabled the client to accelerate development and secure timely delivery of their next-generation IVI platform.

How We Fit

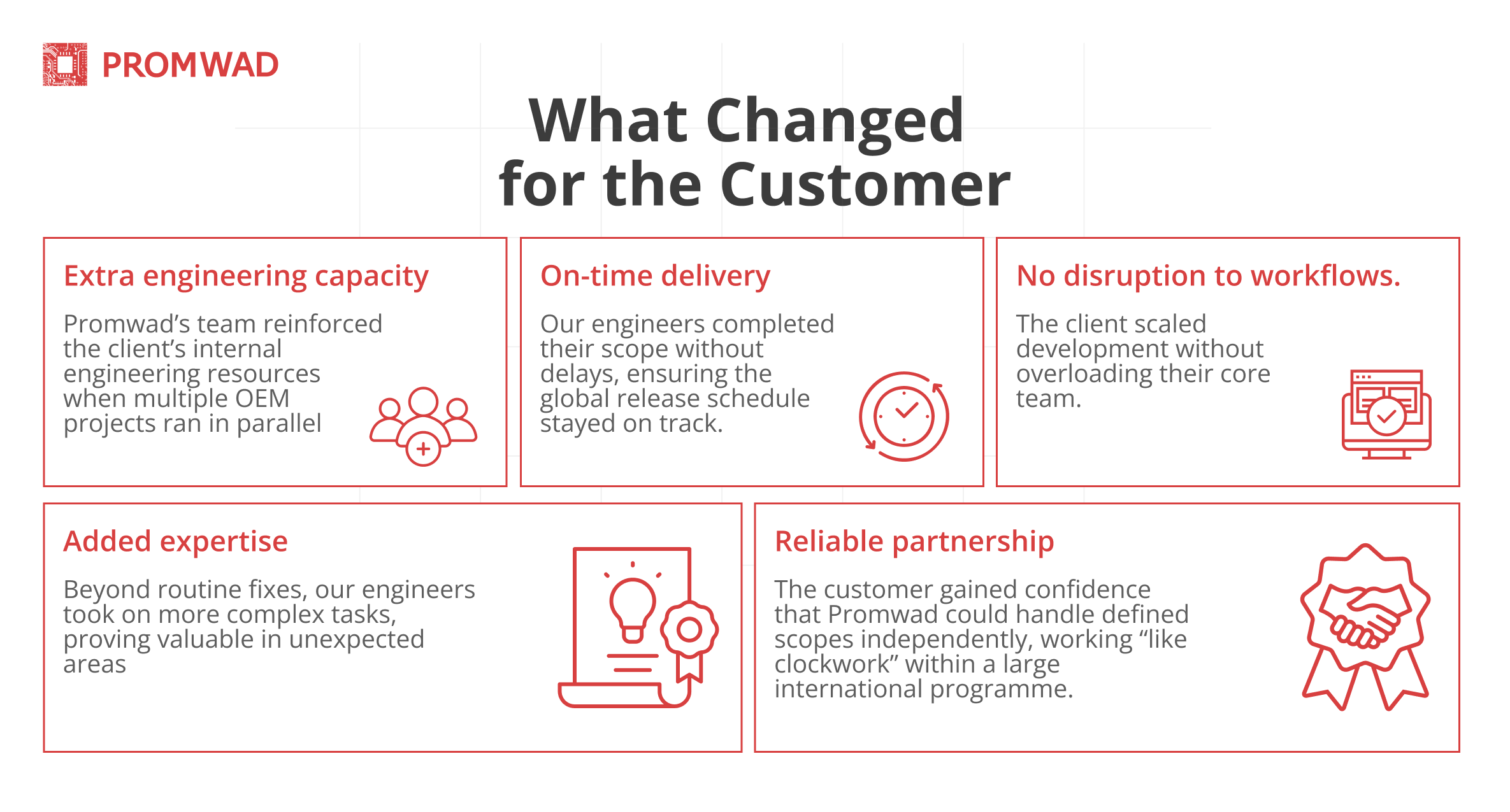

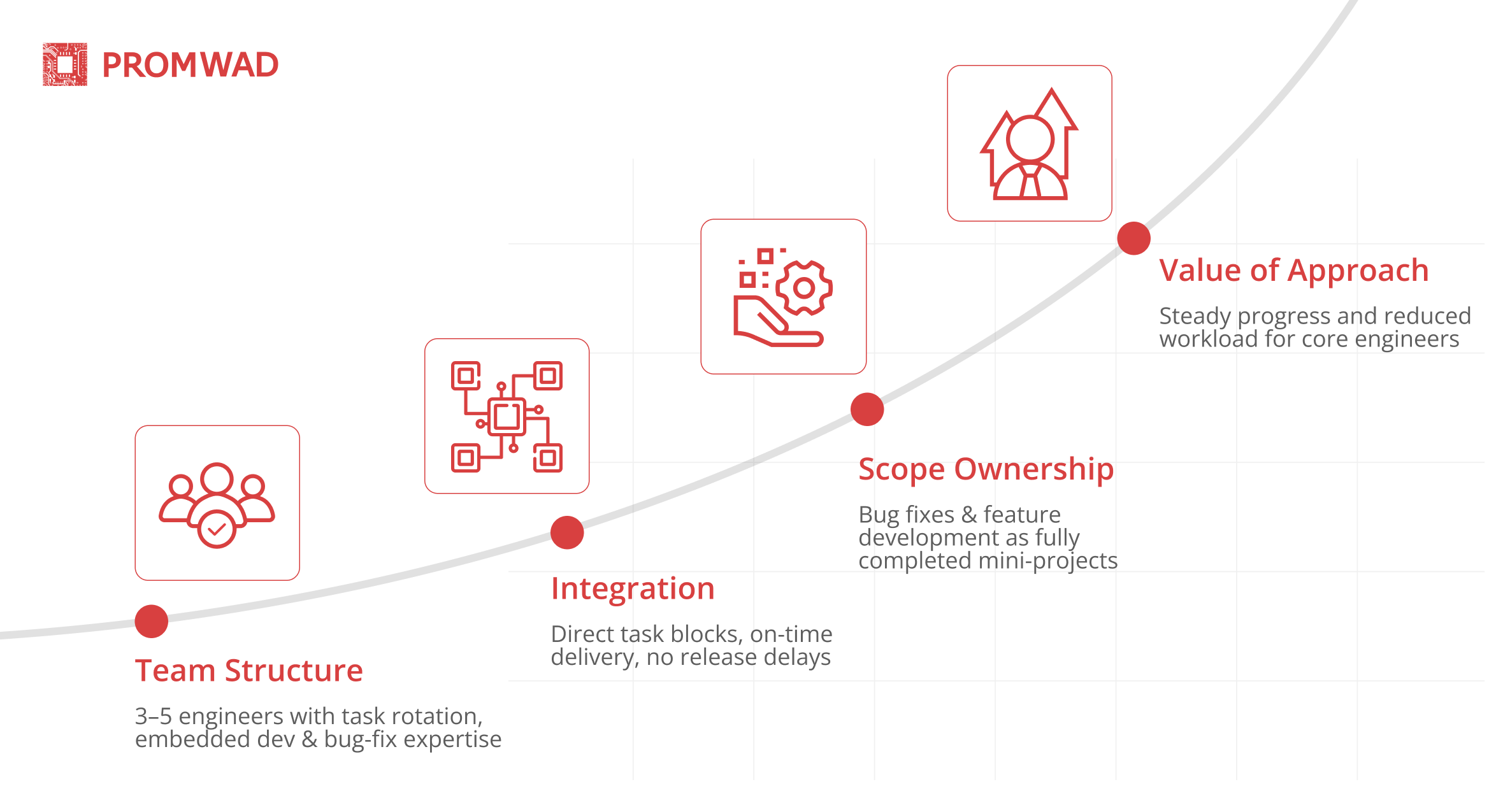

To address the client’s immediate capacity gap, we assembled a compact but highly effective dedicated team. Their role was to integrate smoothly into the existing workflow, take ownership of specific sub-tasks, and ensure that nothing in the larger programme was delayed because of missing resources.

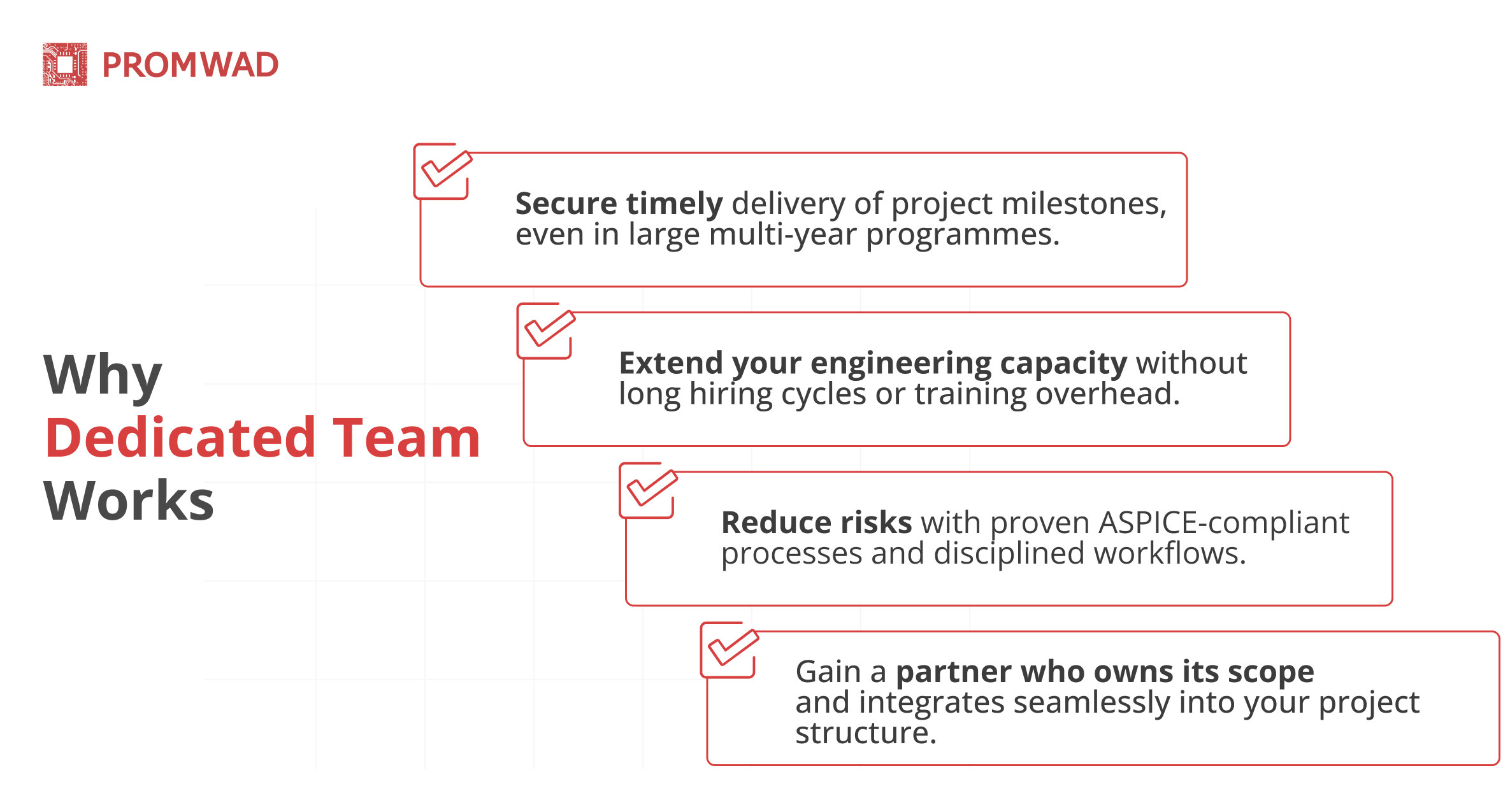

Why Dedicated Team Works

When automotive suppliers face simultaneous programmes for several OEMs, even strong internal teams can struggle to keep pace. A dedicated team provides the flexibility to scale instantly, deliver defined scopes, and ensure deadlines are met.

Solution

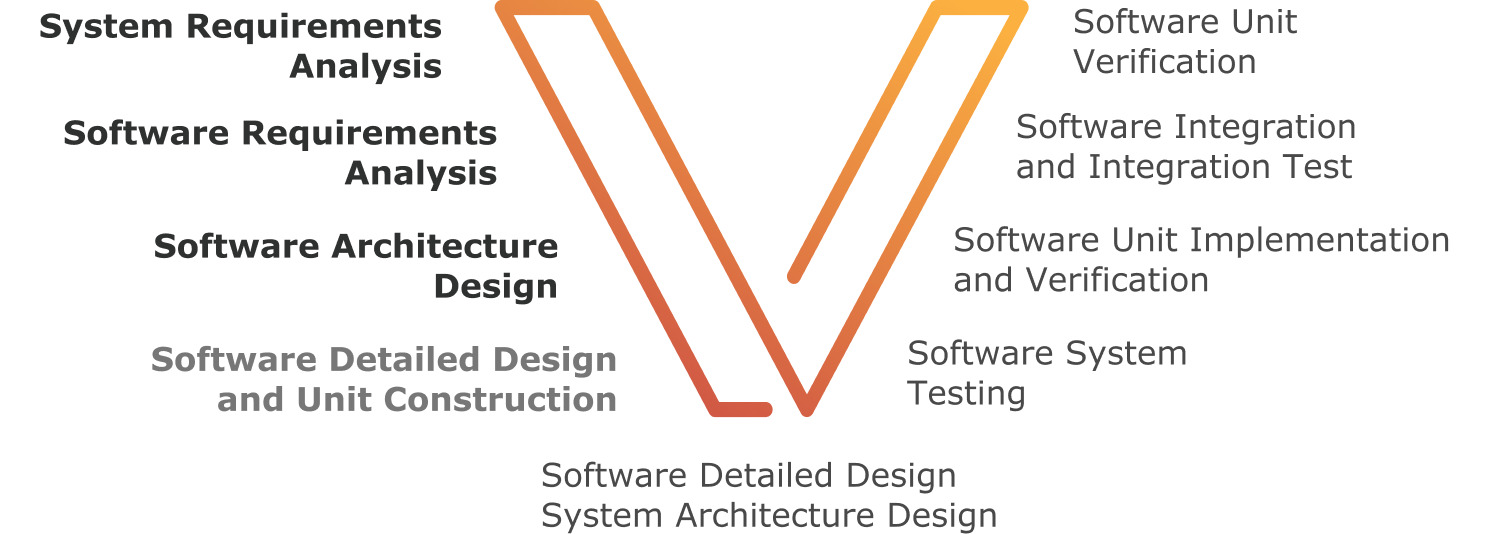

All work was performed in strict accordance with ASPICE standards, which ensure a clear distribution of roles, areas of responsibility, key practices, and necessary artefacts.

1. Hardware Testing & BSP Development

The client's device is based on the SA8155 SOM from Qualcomm. The Promwad team developed software for testing the hardware and created a board support package (BSP) to work with it. As part of these tasks, we did the following:

- configured the Linux operating system to test all components of the device;

- ported the QNX and Linux operating systems for use in the final version;

- adapted the audio system to the client's equipment, including support for inputs and outputs;

- ran the video subsystem on QNX and configured drivers for serial data transmission from the cameras;

- developed drivers for controlling audio codecs — chips that convert digital audio to analogue and vice versa;

- customised the interface for working with cameras;

- developed drivers for Wi-Fi and Bluetooth;

- resolved the issue with GPIO interrupts to ensure the operating system responds correctly to hardware signals;

- added support for GPIO expanders in QNX to increase the number of I/O ports.

2. Software Architecture Design

The second direction of our team's work in this project is to analyse the software requirements and develop its architecture for Linux and QNX. The architecture was developed in accordance with ASPICE: SWE.2. This ensured the IVI architecture remained traceable through defined components, interfaces, and documented scenarios under an ASPICE-aligned development flow.

Realised project stages in accordance with the V-model of software development

As part of the architecture design, we performed the following tasks:

- Defining architectural elements: This involved identifying applications, services, and libraries, specifying the subsystems they will operate on, and detailing their interactions with each other and the system's components.

- Defining the required and provided interfaces for each component.

- Building diagrams of architectural elements and components, specifying the relationships both within these elements and with external components, including internal and third-party applications, libraries, and services.

- Preparation of documentation: description of the functionality of the interfaces. The documentation should contain information about the data types used in functions or classes. In addition, you should describe which external interfaces the component needs for correct operation, i.e. which other modules or systems it uses.

- Creating sequence diagrams that show how the architecture is used in practice. The diagrams show the order in which the functions or methods of the components are called to fulfil specific system scenarios.

Business Value

As a result of the completed steps, our customer received a customised and comprehensive board support package (BSP), enabling efficient system testing and integration. The architecture for QNX, Linux and AUTOSAR operating systems, developed in accordance with ASPICE SWE.2, established a robust foundation for the next-gen IVI system. As the project progresses, the client will receive software that, with the architecture as its foundation, ensures reliable, seamless operation of the IVI system, along with smooth navigation and connectivity.

More of What We Do for Automotive Embedded Systems

- Software-Defined Vehicle: explore our services for the development of customised software-defined vehicle solutions.

- IVI Hardware & Software: a case study on the development of a hardware & software platform for IVI systems commissioned by Alpine Electronics of America, Inc.

- What's New in ASPICE 4.0: read our study on key updates and improvements to the ASPICE 4.0 standard.