Real-Time Rail Safety Platform for Multi-Sensor Data

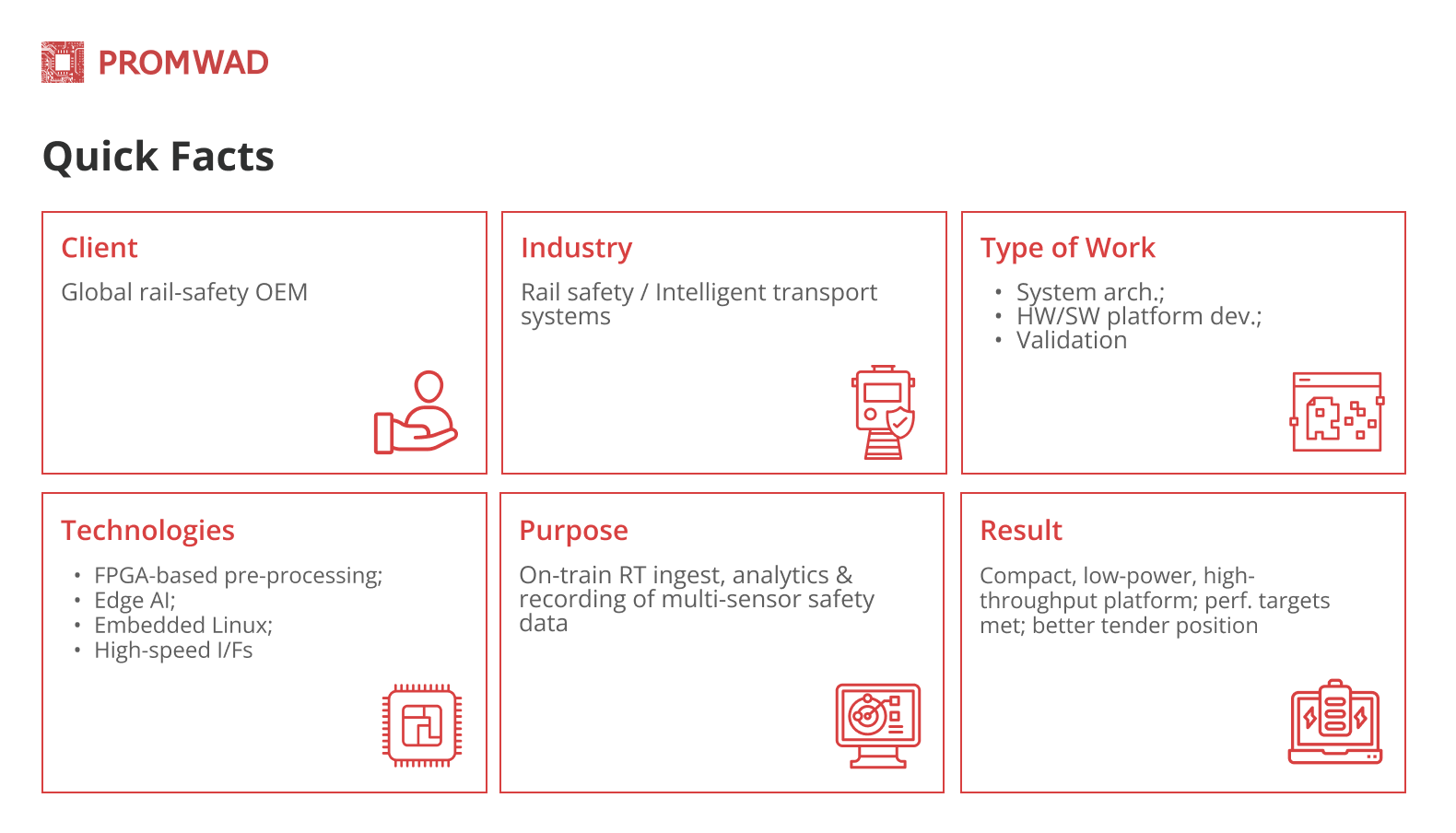

Project in a Nutshell: We built an onboard rail-safety data platform for a global OEM to convert dense multi-sensor streams into reliable, real-time insight. The solution combines an edge AI computing module for analytics with an FPGA-based pre-processing layer.

In a compact, power-efficient form factor, it sustains high throughput and low latency from multiple sensors. With this platform, the client can offer turnkey packages that combine sensors and computing for large rail operators.

Result: stronger bids in international tenders, faster certification and rollout, and a clear path to next-generation safety features.

Client & Challenge

Our client is a company that develops railway safety solutions. They needed a compact, energy-efficient, and highly productive onboard platform: new generations of radars and other sensors generate massive data flows that must be received, filtered, classified, and reliably recorded in real time on the train.

Their existing architecture was approaching its limits in terms of performance, size, and scalability, which could slow down future deployments and make it harder to compete in new tenders. Together with the client, we clarified the business goals and risks and defined the target platform profile for the next generation of their solution.

Solution

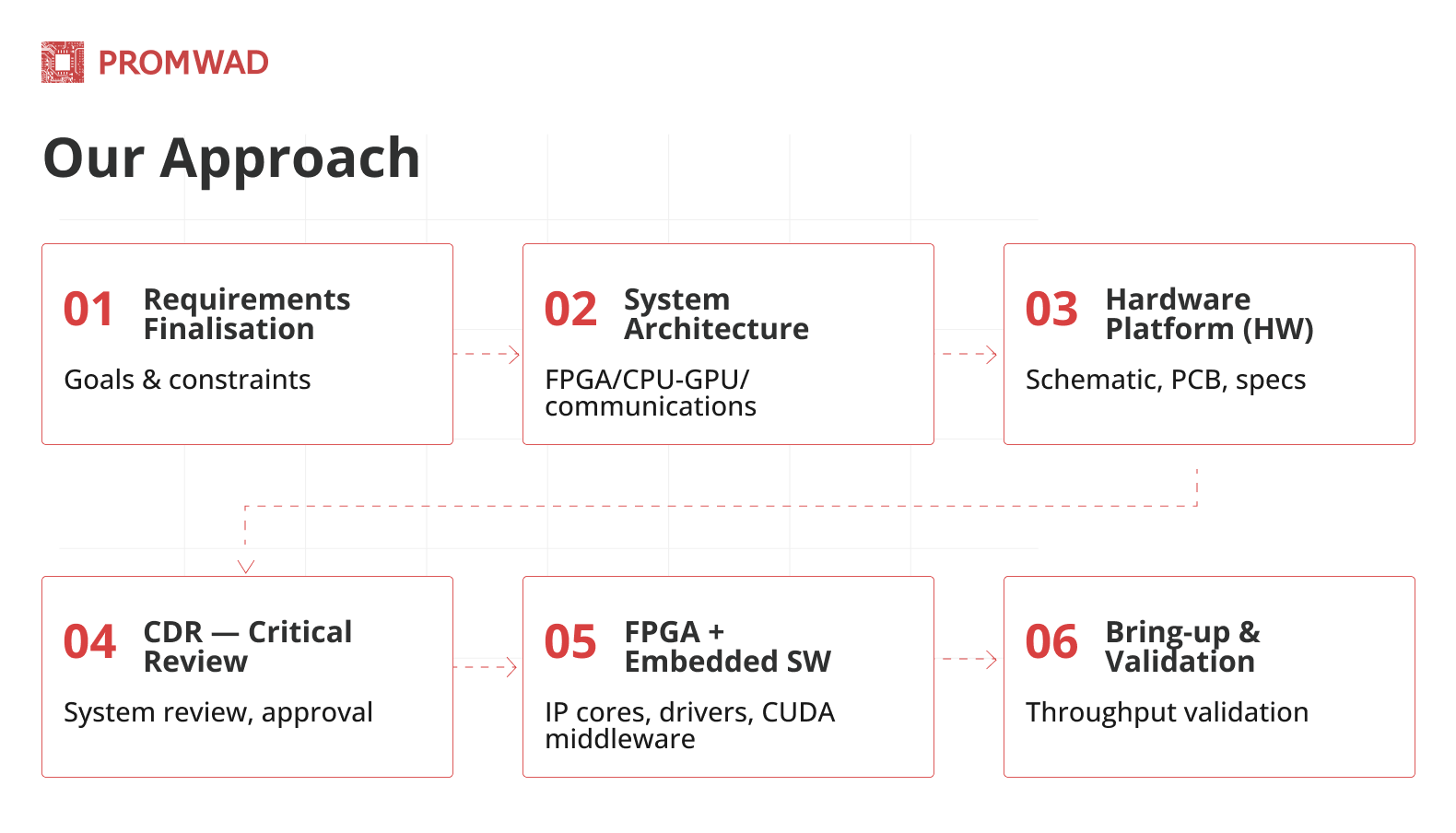

We designed a two-layer platform: one part receives and pre-processes sensor data in real time, the other runs analytics and manages data flows under Embedded Linux. The device works autonomously on the train, without an external host PC.

Inside the platform, sensor data is routed through separate paths for streaming, operator connections, and local recording. This avoids internal bottlenecks, keeps latency predictable, and makes integration with different back-end systems easier.

From the start, we aimed the hardware at very high data rates but limited the first revision to the interfaces and configurations needed for the current use cases. This focus reduced design complexity, sped up development and manufacturing, and created a solid base for future versions of the device.

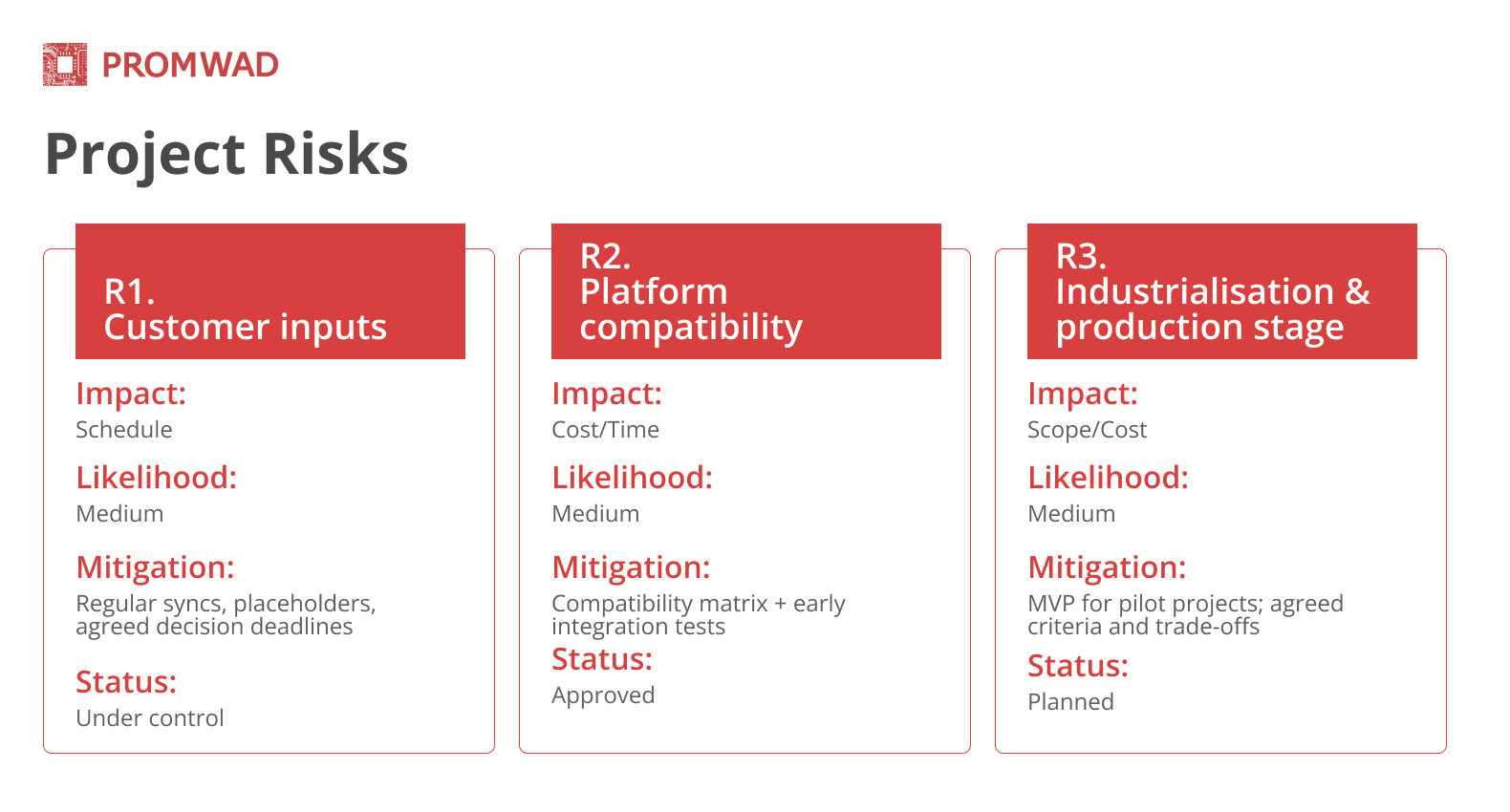

During the project, we identified several key risks and addressed them proactively; the infographic below summarises the top three:

The work is structured as a joint project: the client has access to our repositories and artefacts, and their engineers participate in circuit/power/mechanics reviews, as well as acceptance tests. We synchronise every week and jointly record key decisions. This mode and transparency provide overall control over deadlines and quality.

This project reflects our expertise in ECU and embedded platform development: we create compact, energy-efficient onboard computers that combine FPGA pre-processing with Embedded Linux analytics to process dense radar and multi-sensor streams in real time. We develop deterministic data paths for streaming, operator access, and local recording to ensure high throughput and predictable latency in safety-critical transportation scenarios.

Business Value

The project is ongoing: we have confirmed that the platform meets the required performance and are now preparing the detailed design, manufacturing, and the device's first validation.

The compact platform supports high-density sensor data and delivers reliable, real-time insights on the train. This lets the client offer turnkey safety solutions — from sensors to onboard computing — and strengthens their position in large international tenders.

Going forward, the platform can be extended to include new analytics algorithms, next-generation devices, and adaptations for other modes of transport.

More of What We Do for Automotive & Transportation

- Automotive Services: explore our full range of automotive services.

- Standalone Modular DAQ: сheck out this case study of LV-LOG developed using Microchip technology for Klaric.

- Transforming the German Automotive Industry: read our article in EETimes, in which our expert discusses how engineering innovations have transformed the German automotive industry.

FAQ

What do your automotive ECU development services include?

We program and optimise electronic control units to ensure safe operation of multiple vehicle modules and systems in electric, hybrid, and internal combustion vehicles. We also develop telematics, access and control systems, and solutions for HVAC, hydraulic, and pneumatic systems.

What types of ECUs and modules do you develop?

We create solutions such as body and chassis control units, lighting solutions, security systems for vehicle access and control, and EV-related solutions. Our scope also covers cab control units and HVAC solutions.

Which standards guide your ECU software development?

Our ECU software development is guided by AUTOSAR, ISO 26262, and ASPICE. We also highlight compliance with ASPICE 4.0, ISO 26262, and ISO 9001:2015 in our automotive engineering services.

What technologies and platforms do you use in ECU development?

We work with C/C++, C#, and Rust, and use CAN/LIN and Ethernet interfaces, with make/cmake build systems. Platforms include bare metal and RTOS (FreeRTOS, A-FreeRTOS, Zephyr, TiRTOS, Azure RTOS), and tools such as Eclipse-based tools, Visual Studio, and Segger programming tools.

Why Promwad for ECU and broader automotive electronics development?

We bring cross-functional experience to analyse the vehicle comprehensively and ensure seamless overall performance and functionality. Our engineers develop vehicle electronics up to ASIL-C functional safety level and use structured practices across requirements (Polarion traceability), architecture (UNM and SysML), CI/CD, and validation & testing (including dSPACE or custom HIL benches).