ISOBUS Solutions

ISOBUS Solutions and ISOBUS Stack Development

Do you want to enable data exchange between agricultural equipment from different manufacturers? Consider the ISOBUS protocol (ISO 11783) to simplify operator tasks by removing additional devices in the cab.

Our custom ISOBUS stacks connect implements such as seeders, tillers, sprayers, and irrigation systems to the central display of a tractor or harvester. With the "plug-and-play" solutions, you can automate setup and coordinate operations immediately.

What We Do

Our team develops and integrates custom or open-source ISOBUS stacks for tractors and implements. Additionally, we design clusters and HMI displays to present all information transmitted via ISOBUS.

Whom We Serve

Our end-to-end services are ideal for manufacturers of agricultural machinery and implements.

Egor Isaev, Business Development Manager at Promwad

Our ISOBUS Solutions

- CAN gateway

- IO gateway

- ISOBUS gateway

- ISOBUS stack development

- ISOBUS stack integration

- Message analysis tool

- Development tool for high-speed ISOBUS

The ISOBUS Protocol Provides

- Standardisation of connectors, cables, and functionalities

- Power consumption regulation

- Robust data exchange

- Extension of equipment functionality

- Documentation of all operations

- Process facilitation for tractor operators

Agricultural Machinery and Equipment We Work With

![]()

Tractors

![]()

Tillers

![]()

Harvesters

![]()

Sprayers and Irrigation systems

![]()

Balers

![]()

Ploughs and Cultivators

![]()

Spreaders

![]()

Livestock feeders

![]()

Chippers/shredders

![]()

Fruit graders

Explore Our Case Studies

Integrated control system design

We created an integrated control system for gear shifting, rear and front PTO drive, rear axle differential lock, and front drive axle drive.

The system monitors and displays the status of various sensors on the front panel. Additionally, the solution controls its power circuits for short-circuit and no-load.

Key features:

- Front & rear power take-off shaft (PTO)

- Gearbox

- Front axle drive

- Rear-axle differential lock

* Photo for illustration purposes only. John Deere CommandViewTM III Cab.

Dashboard software for agricultural machinery

We designed a harvester dashboard solution with a lightweight graphical interface to control the harvesting process.

Technologies we used in our farm machinery design process:

- Atmel’s MCU

- CAN, LIN sensors

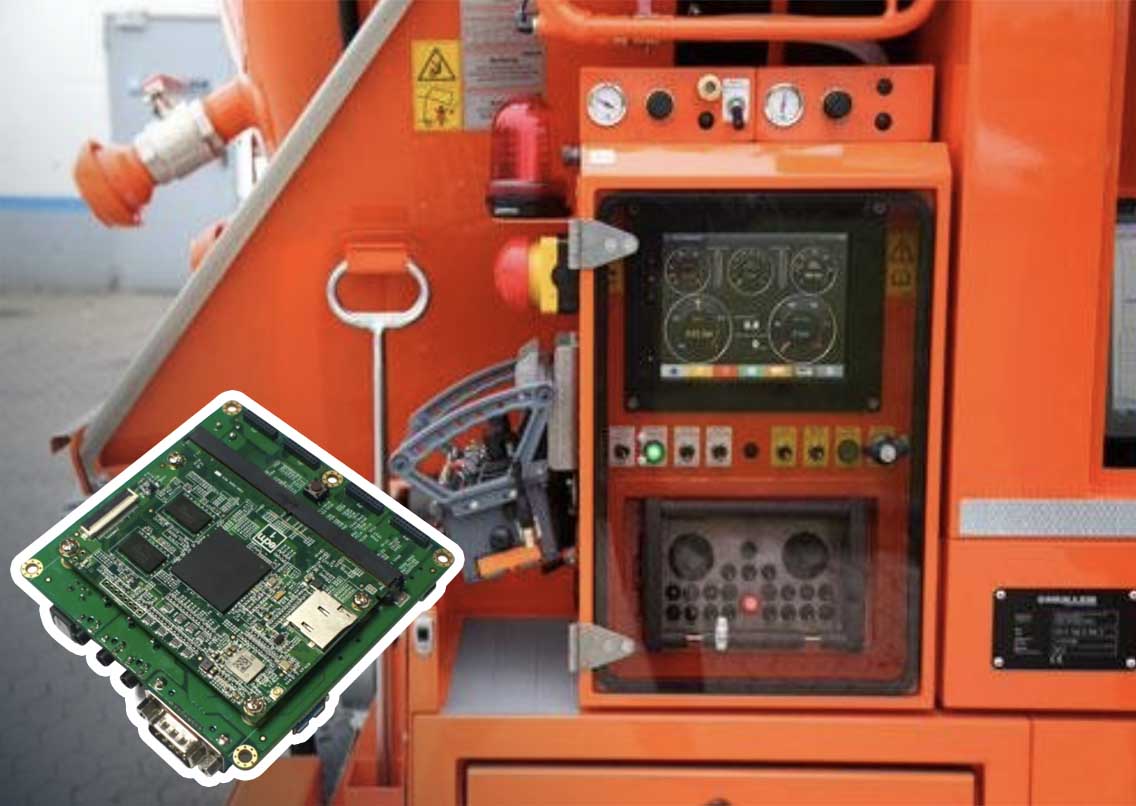

Dashboard for sewer cleaning truck

We developed the dashboard software for a company manufacturing sewer cleaning and waste disposal trucks.

Technologies we used in our software design for agricultural equipment:

- IMX6 dual-core Cortex-A9 CPU

- Embedded operating system

- 11’ TFT display

- Qt library

- GPS

- CAN

- 3G

Why Promwad?

Leading vendors & portfolio

Our partnerships with the best vendors on the market and extensive automotive portfolio give us a solid competitive edge.

Efficiency & flexibility

Our experience allows us to deliver any automotive project cost- and time-efficiently while offering our clients flexible cooperation models.

Do you want to get a quote for our ISOBUS stack development services?

Drop us a line about your project! We will contact you today or the next business day. All submitted information will be kept confidential.