Moulding

Design

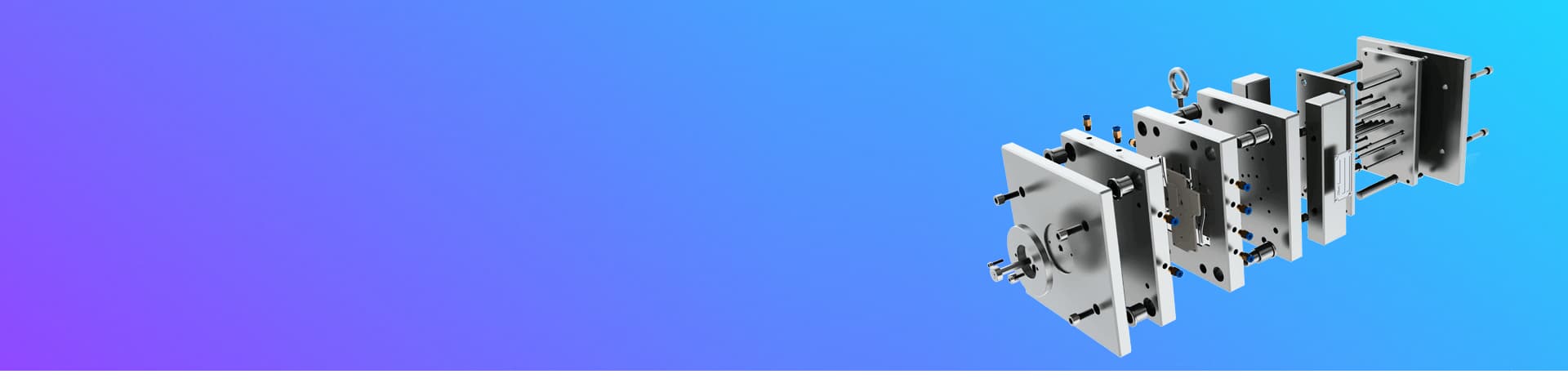

Сustom Injection Moulding Design Services

Сustom injection moulding design provided by Promwad Manufacturing team includes a wide range of plastic cases and housing for electronics, from small and intricate parts to large and complex solutions.

As a plastic mould design company, we develop solutions to help you produce plastic parts or tooling for the production of high-quality enclosures for electronic devices.

Custom Mould Manufacturer for Your Business Goals

Promwad is a custom mould manufacturer with a portfolio that includes more than 3 million devices manufactured for our customers worldwide. We deliver ready-made products that fully comply with your vision.

While designing and manufacturing moulds, our team performs tasks of any complexity, following your requirements and using the most up-to-date software tools and equipment.

The experts of Promwad Manufacturing have vast experience in designing and producing electronics enclosures. Our industrial design team has been developing its portfolio in custom injection moulding services since 2004.

What We Do

With our expertise, we deliver accurate and reliable moulds, ensuring your product meets the highest quality standards:

Why Promwad

Expected Result

The Promwad team guarantees the achievement of the declared outcome at the production site

Quality Assurance

We ensure that your product is free of any manufacturing defects that may have occurred during the manufacturing process

Standards Сompliance

We guarantee that all our products meet industry standards for safety, quality, and environmental impact

Enclosure Injection Mould Design

We provide injection moulding design and manufacturing for various production processes and materials (plastic, rubber, etc.), create and optimise their design, and run tests to ensure the highest quality of finished products at the production site.

To test the product for assemblability and test its usability, we make a prototype with a 3D printer. The customer receives a prototype, which is close to the final product in quality. We can offer custom injection moulded enclosures or find a ready-made enclosure for your project.

“We help our customers achieve success in industrial design. Promwad's portfolio includes devices that stand out in the world market, such as a set of Lapka iPhone sensors, the Qoobi One award-winning device, and other products that have become popular mainly due to successful enclosure solutions. We work only with proven manufacturers in Europe and Asia, who guarantee high quality and adherence to deadlines.”

— Ivan Kuten, Managing Director & Tech Advisor at Promwad GmbH

Our Case Studies on Custom Enclosure Moulding

Do you need a quote for the mould design and manufacturing for your enclosure?

Drop us a line about your project! We will contact you today or the next business day. All submitted information will be kept confidential.