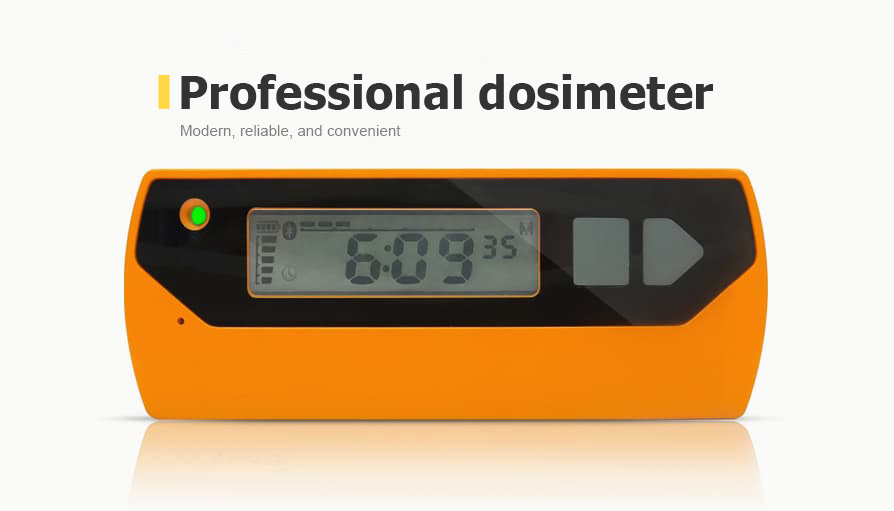

Dosimeter enclosure development

Client

A European company, which designs and manufactures devices for measuring radiation levels. It was the first company in the world to develop a device combining in itself a search pager and a dosimeter. It is also the world's only serial producer of wrist dosimeters.

Challenge

The customer turned to us to upgrade the professional dosimeter's enclosure and finalize its printed circuit board.

Requirements to the enclosure design:

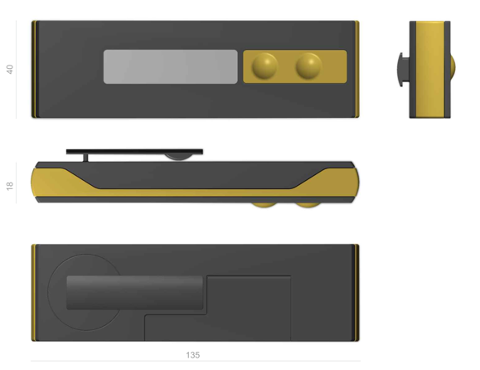

- The PCB layout must specify the device dimensions. The front panel should have a display, LED, and two control buttons.

- Device appearance should be reliable, strict, and modern.

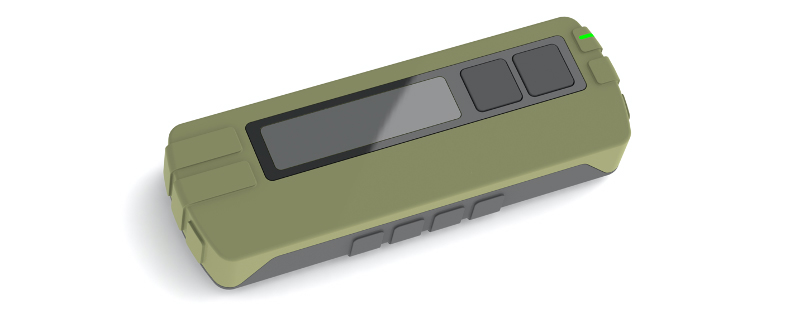

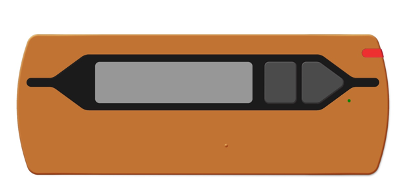

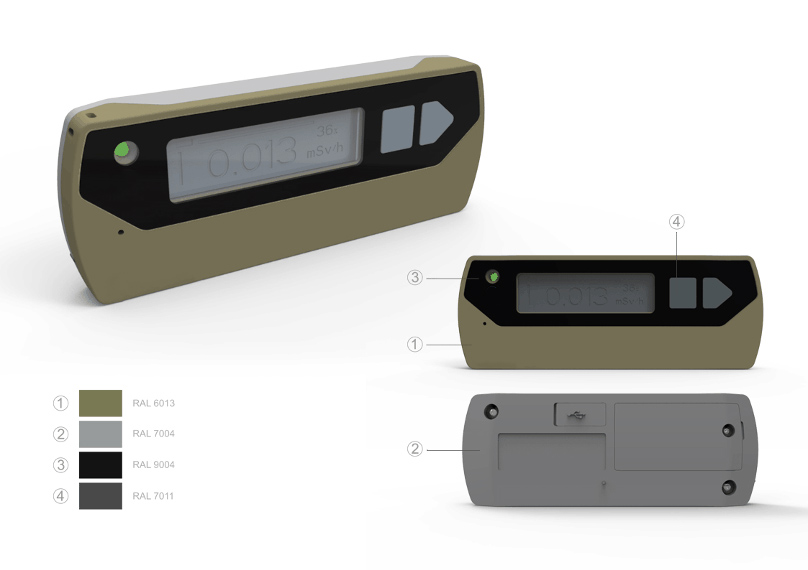

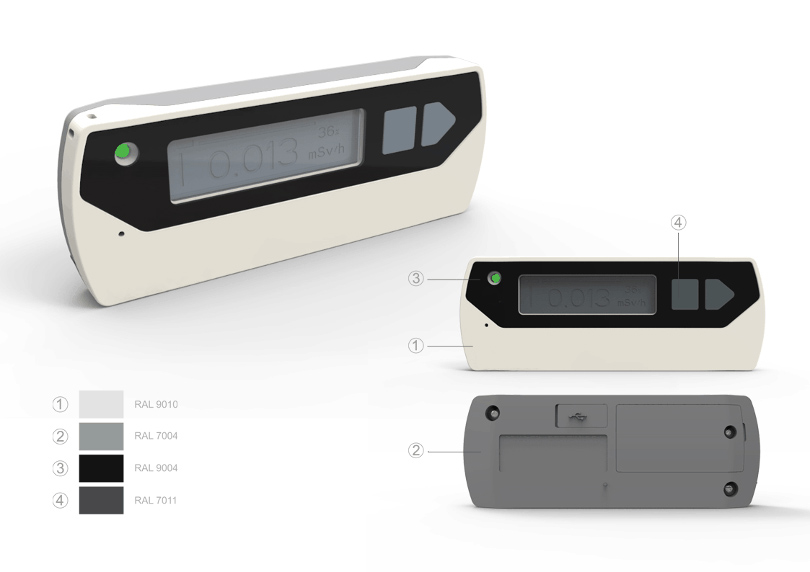

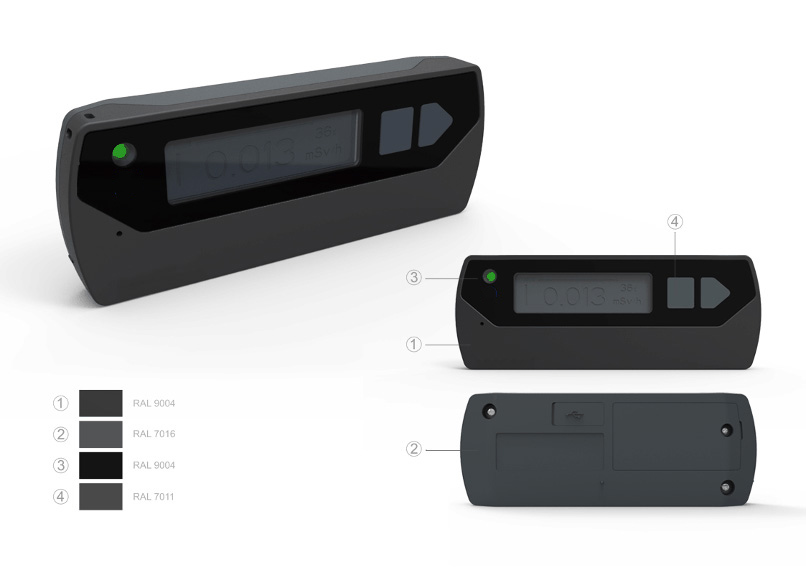

- Style requirement is in the diverse color spectrum (classic black, bright orange, neutral gamma – shades of gray or muffled green).

- To protect the connectors with rubber plugs and the battery compartment with a secure cover.

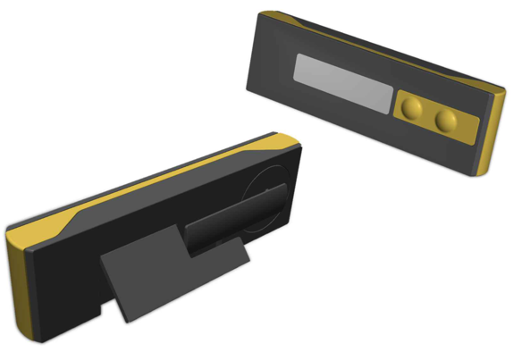

- To provide bearing and a clip for fixation in pockets.

Solution

1. Industrial and mechanical design

We proposed several design options. The project’s overall concept was the following: a professional device that looks reliable, concise, user-friendly, and convenient.

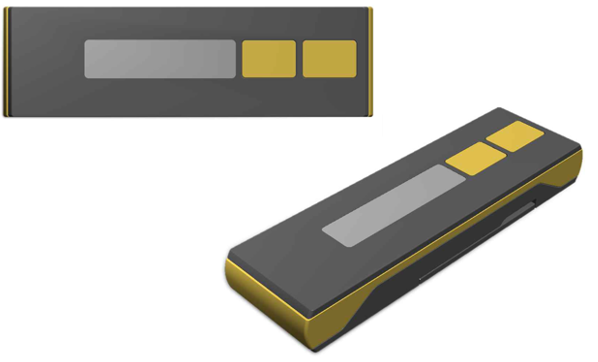

Design option 1

The buttons are glued rubber mat with a high level of protection. The required clip and bearing are separate.

That option is simple and reliable. The clip helps remove the battery cover. The clip serves as a grip to remove the battery cover. Fastening the battery cover is offered as a thread or bayonet (with rubber gasket) for a high degree of protection (IP).

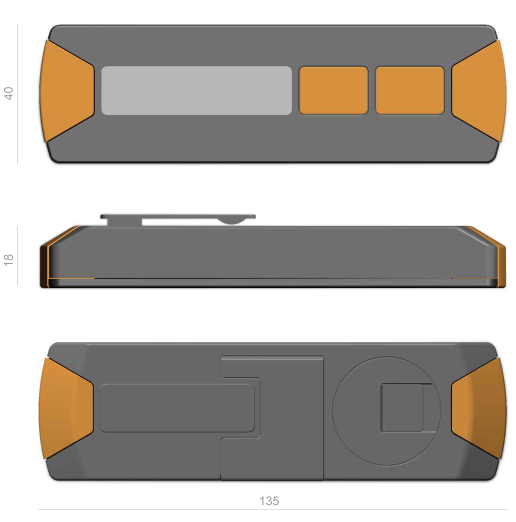

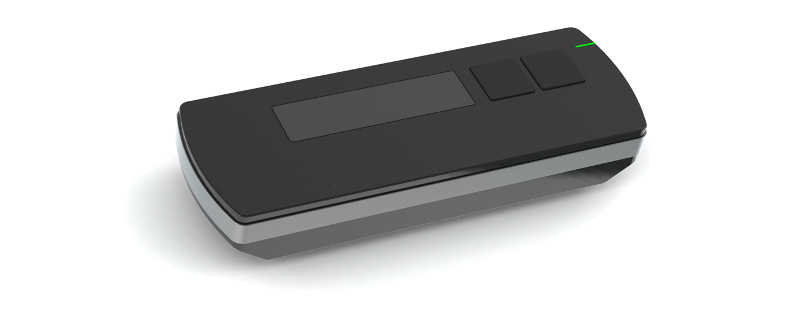

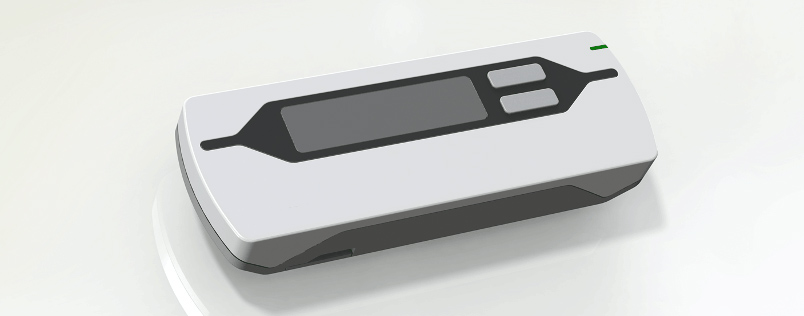

Design option 2

The second option also implies rubber buttons, but the difference is how they are inserted: from the inside like on the remote controls. There is also a modification with plastic buttons with rubber gaskets made on the same level as the front panel. That protects from accidental pressing.

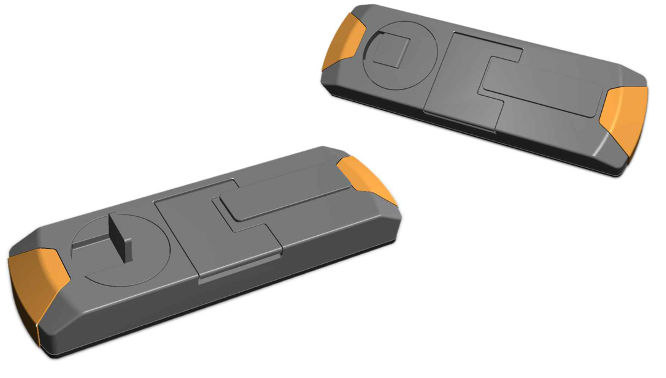

Design option 3

That option is ergonomic through the side inserts from rubber, “rubber” paint or matte plastic, and folding grip for turning the battery cover.

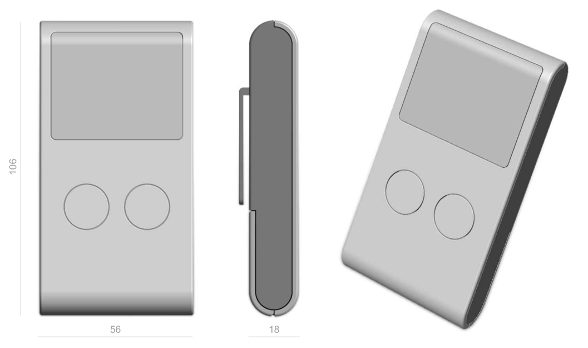

Design option 4

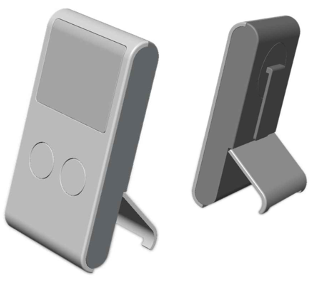

The advantage of the vertical option is in a comfortable grip and the possibility to control the device with one hand (as a phone). The disadvantage is that the indicator needs other proportions.

We choose options 2 and 3 for further development.

Option 2.1

Option 2.2

Option 2.3

The client approved the design option 2.2 and asked to finalize it for different customer segments, namely non-professionals, law enforcement agencies, and emergency services.

At the next stage, we were working with details, materials and color schemes.

The final design option became bright, concise, and convenient. The enclosure elements’ colors supplement the unusual line of the connector details. Large rubber buttons provide a comfortable push; their design eliminates accidental pushing. The back cover of the enclosure is convex and narrow along the edges to hold the device comfortably.

2. Enclosure development

The customer proposed to make the dosimeter glass of polycarbonate with the help of injection molding. We studied the ability to spill and casting defects. As a result, we had to abandon this option due to possible distortion.

Providing the fact that the production launch budget was limited and the results of computer modeling, we decided to produce the glass by laser cutting, without a clip for the battery compartment cover and bayonet mechanism, which increased the device's size.

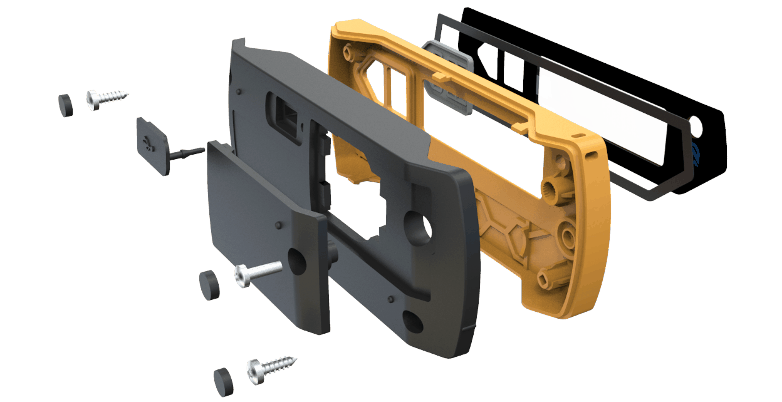

The main task of the designer is to minimize the number of tooling for mass production. Industrial and mechanical designers' joint work minimized the number of tooling for mass production without loss in appearance.

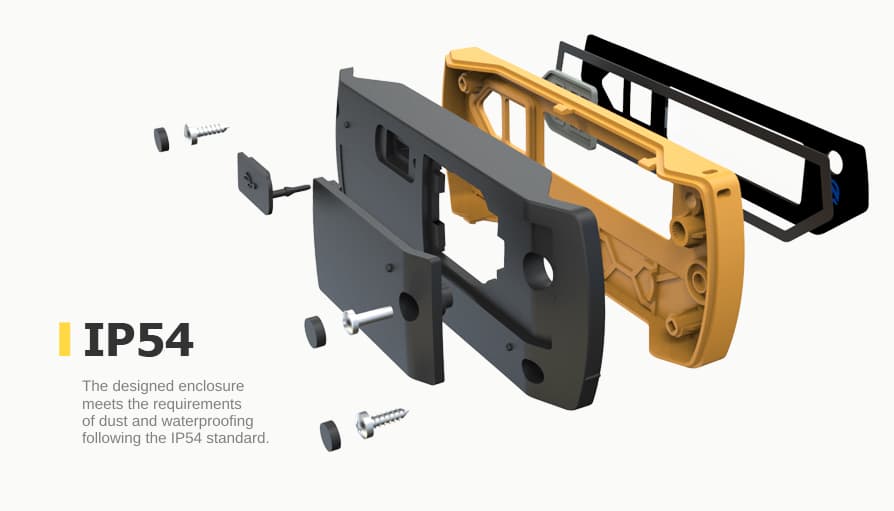

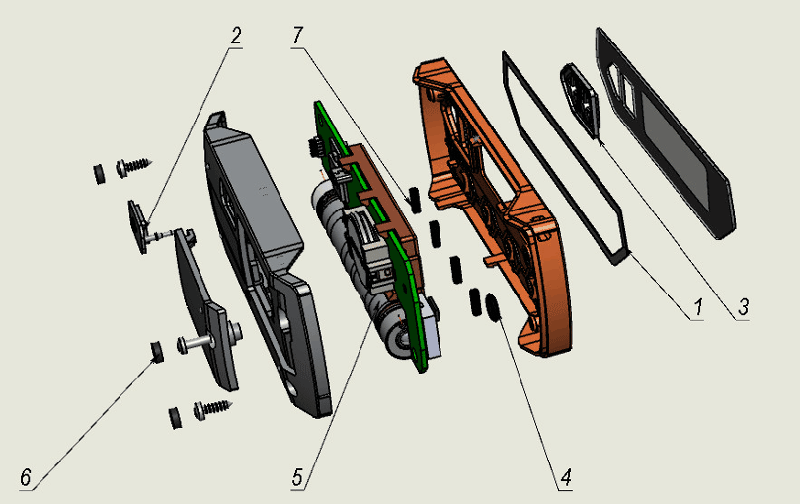

We carried strength calculations on the design stage to ensure the stiffness. As a result, we decided to assemble and disassemble the device using three screws. The number of parts was minimized.

A rubber gasket (1) between the glass and the enclosure ensures the IP54 level of protection. The glass is outside the enclosure. Micro-USB protection reaches through a rubber plug (2). Buttons (3) are also of rubber. Standard rubber gaskets (4) are for speaker protection. There is an ability to install two sensors with different sizes (5). The screws are hidden in the enclosure using standard plugs (6). Rubber seals (7) protect the sensor from drops and vibrations.

Business value

The designed enclosure meets the requirements of dust and waterproofing following the IP54 standard. Design improvements made it possible to achieve minimum production cost. At the final project stage, we made prototypes in three colors by the milling method. The customer's management and marketing department were satisfied with the quality of the prototypes.

The dosimeter has an additional function of clock and alarm. The extended version of the device includes a GPS receiver for fixing the coordinates of measurements and a Bluetooth 4 module for wireless transmission of results to a PC or smartphone. The internal design of the enclosure allows the installation of several Geiger–Muller sensors.

The device is for a broad audience. Non-professional users will use it at home, rescuers in emergency zones, border and customs services for cargo inspection.