Structural Battery Composites in 2026: Where the Concept Breaks, Where It Starts Working

Structural battery composites sound almost too elegant to be real. A material that carries mechanical loads and stores energy at the same time feels like the kind of idea engineers love and manufacturing teams fear. For years, it lived mostly in research labs and conference presentations.

By 2026, the conversation has shifted. Structural batteries are still not everywhere, but they are no longer treated as a curiosity. What has changed is not just performance, but understanding. The industry now has a clearer picture of where structural battery composites make sense, where they don’t, and what trade-offs cannot be wished away.

This is no longer a story about replacing lithium-ion cells. It is a story about system-level redesign.

What structural battery composites really are in practice

At a basic level, structural battery composites combine two functions that used to be separate: mechanical strength and energy storage. Carbon fiber plays a central role because it can act both as a load-bearing element and as an electrode. A solid or semi-solid electrolyte binds the structure together while enabling ion transport.

That sounds simple. In practice, there are two very different paths.

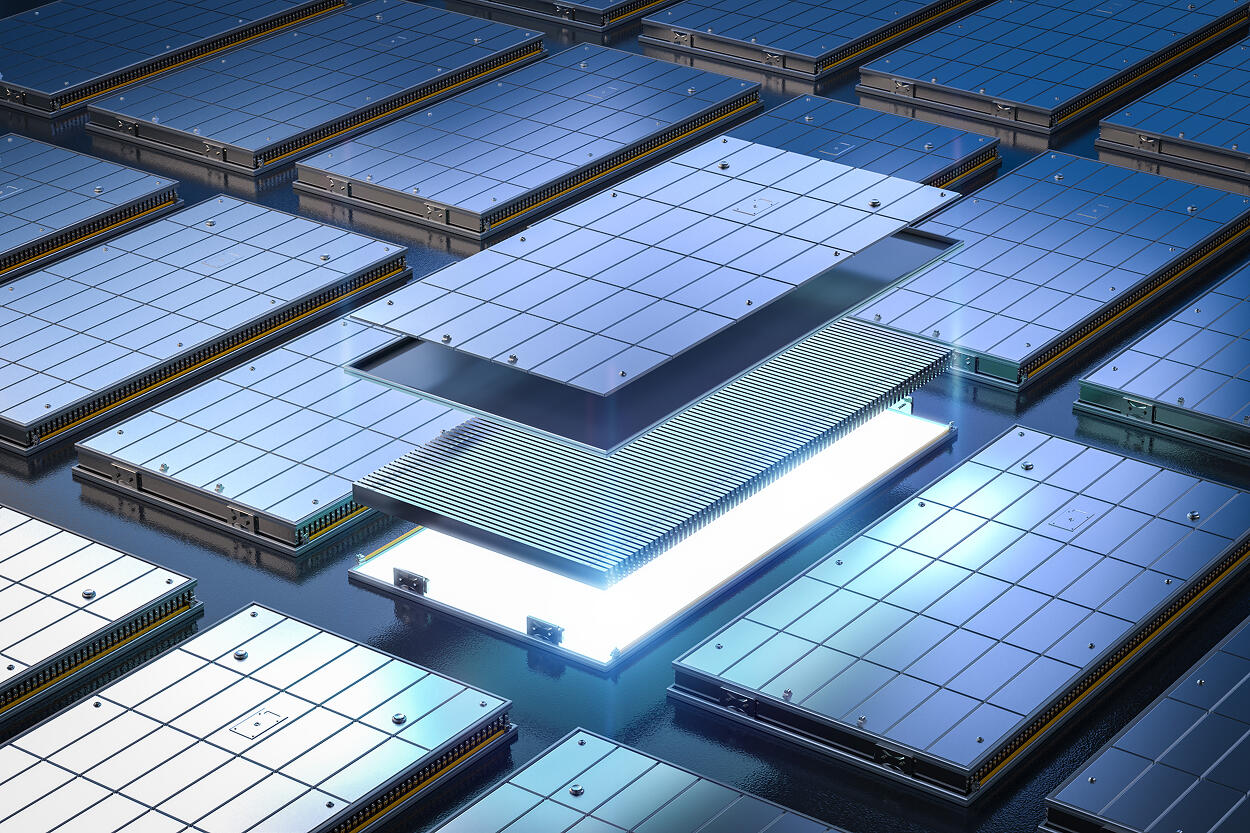

One approach embeds conventional battery cells into structural panels. The panel becomes part of the load path and the battery pack at the same time. This is conceptually closer to existing manufacturing and easier to reason about from a safety standpoint.

The more ambitious approach uses the fibers themselves as active electrochemical components. In that case, the material is not “battery plus structure,” it is the battery. This is where the real weight and volume savings live, and also where most of the engineering pain begins.

How good are structural battery composites in 2026, really?

This is the question everyone asks first, and the answer is nuanced.

Are structural batteries competitive with lithium-ion cells on energy density?

No, not on a cell-by-cell basis. Typical structural battery composites still store less energy per kilogram than state-of-the-art lithium-ion cells.

But that comparison misses the point.

Structural batteries eliminate housings, frames, fasteners, and protective casings. When you look at the system level, not just the chemistry, the gap narrows significantly. In some configurations, overall vehicle or device weight drops even though the energy density of the storage material itself is lower.

Mechanically, the results are no longer academic. Stiffness comparable to aluminum and strength in the hundreds of megapascals are now routine in lab-scale prototypes. Cycle life is no longer measured in dozens of cycles, but in hundreds or more, depending on the design.

In 2026, the technology is no longer fragile. It is just demanding.

Where structural battery composites actually make sense

Structural batteries are not a drop-in replacement for existing battery packs. They only make sense when the product is designed around them from the start.

Where do structural battery composites deliver real value today?

They work best in systems where mass reduction changes everything.

In electric vehicles, weight saved in the body directly improves range, efficiency, and packaging flexibility. A floor panel or roof that carries load and stores energy changes how the entire vehicle is laid out. But it also forces new crash, service, and safety thinking.

In aerospace and drones, the value is even clearer. Every kilogram saved translates into longer flight time or lower launch cost. Structural batteries fit naturally into wings, fuselage elements, or internal frames where traditional battery packs are a design compromise.

Consumer electronics are often mentioned, but here the bar is higher. Thinness and weight matter, but safety margins are tight and manufacturing volumes are unforgiving. Structural batteries may appear first in premium or specialized devices rather than mass-market phones or laptops.

Robotics sits somewhere in between. Structural batteries can simplify internal layouts and free space for sensors or tools, but only if durability and serviceability are solved.

Much of the public discussion around structural batteries still frames them as a near-future breakthrough that will radically change everything from cars to consumer electronics. A broader look at how energy-storing structural materials are expected to reshape transportation and devices highlights why expectations run so high, especially around weight savings, range gains, and new industrial design freedoms. That perspective is useful, but it also reinforces an important distinction: vision and feasibility are not the same thing. The real work now lies in translating promising lab results and market forecasts into systems that can survive manufacturing constraints, safety certification, and long-term use without compromising either structural integrity or energy performance.

Manufacturing is the real bottleneck

Performance numbers get attention, but manufacturing decides whether the technology survives.

Producing a material that must behave like a structural composite and a battery at the same time leaves little room for error. Voids, misalignment, or defects are no longer just mechanical issues or just electrochemical issues. They are both.

Why is scaling structural battery composites so difficult?

Because quality control has to satisfy two different industries at once. Structural integrity standards and battery safety standards do not naturally align. Processes that work for carbon fiber composites do not automatically work for electrochemistry, and vice versa.

In 2026, most progress comes from tightly controlled production environments and low-volume applications. That is not a weakness. It is how new materials usually enter the market.

Safety, testing, and certification are still catching up

If a battery is part of the structure, failure modes change.

Crash behavior becomes more complex. Fire safety needs to be assessed in structural terms, not just electrical ones. Inspection and repair are no longer straightforward. You cannot simply remove a battery pack if it is bonded into the body.

This raises a critical question.

How do you certify a structure that is also an energy storage system?

In 2026, the answer is still evolving. Existing standards were not written for multifunctional materials. New test methods, simulation models, and regulatory frameworks are being developed, often in parallel with the technology itself.

Until these frameworks mature, adoption will remain selective.

Cost and materials reality

Carbon fiber and advanced electrolytes are expensive. Manufacturing processes are complex. Scrap rates matter.

Structural battery composites are unlikely to compete on cost with conventional solutions in the near term. Instead, they target applications where performance gains justify higher material and process costs.

That is why aerospace, premium vehicles, and specialized systems are leading adoption.

What the next decade likely looks like

Structural battery composites are not waiting for a single breakthrough. Progress is incremental.

Energy density will improve, but slowly. Manufacturing will become more repeatable. Safety models will mature. Designers will get better at using multifunctional materials without overloading them with unrealistic expectations.

The most important shift is conceptual. Engineers are learning to think of energy storage as a structural design parameter, not a packaged component. That mindset change matters more than any single performance metric.

Conclusion

Structural battery composites in 2026 sit at an awkward but productive stage. They are no longer speculative, but they are not yet routine. Their value does not come from beating lithium-ion cells at their own game, but from changing the rules of system design.

When weight, volume, and integration matter enough, structural batteries stop being exotic and start being logical. The challenge is not proving that they work, but proving that they can be built, certified, and maintained at scale.

That is where the next real breakthroughs will come from.

AI Overview

Structural battery composites combine load-bearing materials with energy storage, enabling lighter and more integrated system designs.

Key Applications: electric vehicle body structures, aerospace components, drones, robotics, and weight-sensitive electronics.

Benefits: system-level weight reduction, improved packaging efficiency, new design freedoms.

Challenges: lower energy density than conventional cells, complex manufacturing, safety certification, and high material costs.

Outlook: steady adoption in high-value applications as manufacturing and certification mature, with broader use driven by system-level design benefits rather than cell-level performance.

Related Terms: structural batteries, multifunctional composites, carbon fiber electrodes, solid polymer electrolytes, energy-storing materials.

Our Case Studies

FAQ

What is smart dust in practical terms?

Where does smart dust actually work today?

Why isn’t smart dust fully autonomous yet?

What are the biggest risks of smart dust systems?

How do smart dust systems scale without overwhelming networks?