From BOM to Box: Managing the End-to-End Lifecycle of Hardware Products

Introduction: Why Lifecycle Management Is the Key to Hardware Success

Launching a new electronic product is not just about clever engineering. It’s about orchestrating a full lifecycle — from sourcing components and managing design iterations to ensuring reliable manufacturing, testing, and shipping.

For embedded systems, IoT devices, industrial controllers, and consumer electronics, a successful product must move efficiently from BOM to box.

In this guide, we outline the stages, tools, and best practices to manage the end-to-end hardware product lifecycle, minimize risks, and stay competitive in 2025 and beyond.

1.BOM Creation: Your Product Blueprint

The Bill of Materials (BOM) is more than a parts list. It’s a living document that defines:

- Component types, suppliers, part numbers

- Cost estimates and volume availability

- Lifecycle status (active, obsolete, NRND)

- Approved alternates and procurement notes

Best Practices:

- Use digital BOM tools with lifecycle tracking (e.g., SiliconExpert, Octopart Pro)

- Include second-source options early

- Align BOM with Design for Manufacturing (DFM) and Design for Test (DFT)

2.Design & Prototyping: Making Ideas Real

What happens here:

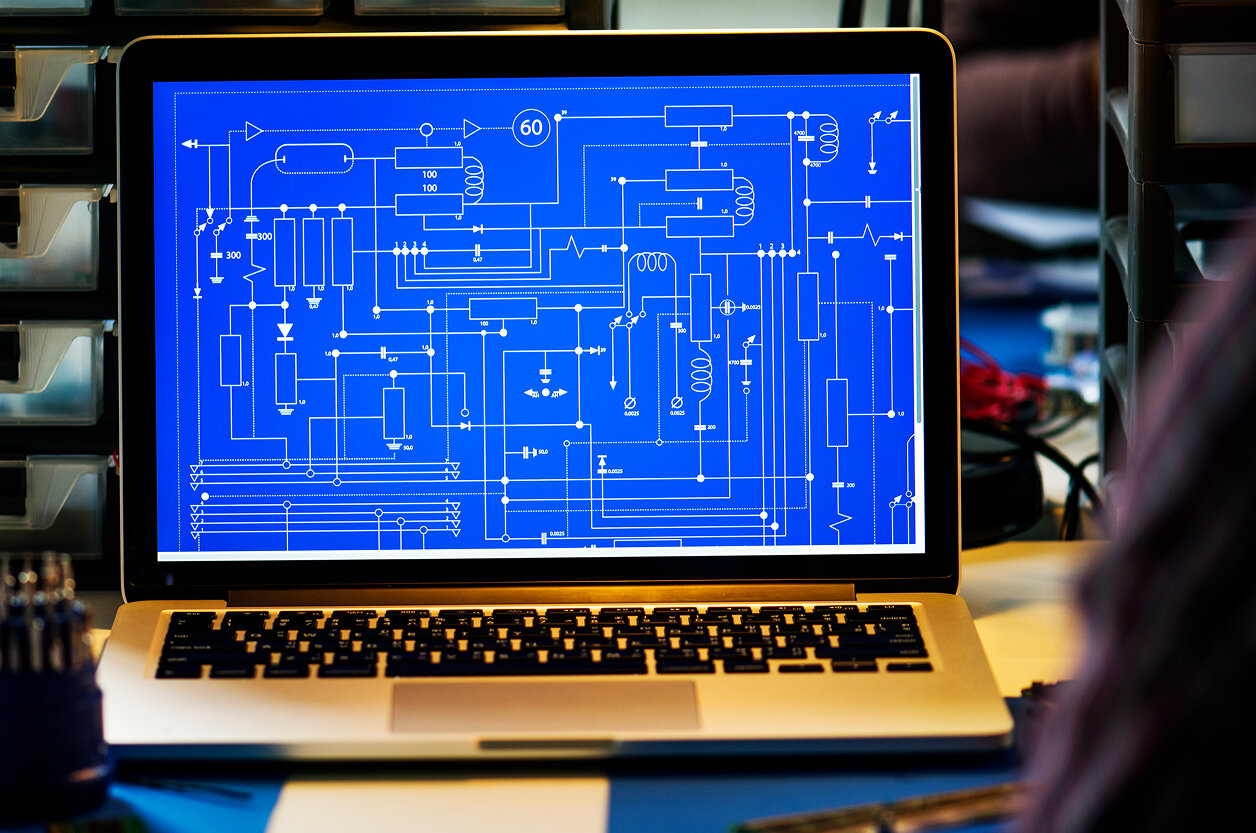

- Schematic capture, PCB layout, and 3D enclosure design

- Embedded software and bootloader development

- Rapid prototyping and first article builds

Tools & Technologies:

- Altium Designer, KiCad, Fusion 360, SolidWorks

- Firmware with RTOS or embedded Linux

- Mechanical and electrical simulation

At Promwad, we support early-stage design reviews with DFM in mind to reduce costly redesigns later.

3.Component Sourcing & Supply Chain Strategy

In 2025, hardware success depends on sourcing resilience. That means:

- Avoiding single-vendor risks

- Monitoring component EOL status

- Building relationships with global distributors and EMS partners

Tactics to Apply:

- Use parametric search engines with availability filters

- Leverage EMS partners’ supply networks

- Consider lifecycle-managed modules (e.g., SoM instead of raw SoC)

4.Manufacturing Partner Selection & Onboarding

Whether working with a regional EMS in the EU or scaling in Asia, the right manufacturing partner must align with your:

- Compliance needs (ISO 9001, ISO 13485, IPC-A-610)

- Forecast volume and quality expectations

- Communication and traceability practices

Onboarding Steps:

- Pilot production and first article inspection (FAI)

- Factory audits or digital QMS integration

- Define packaging, labeling, and shipment specs early

Promwad offers manufacturing transition services, bridging product teams and EMS providers with full documentation and test strategy support.

5.Testing and Quality Assurance (QA)

Types of testing:

- ICT (in-circuit test), functional test, boundary scan

- Thermal, EMI/EMC, environmental testing

- Firmware validation and production flashing

A well-designed test strategy improves first-pass yield and reduces returns. Implementing test points and fixtures during board design pays off during scale-up.

6.Regulatory Compliance & Certification

Depending on your target market, certification is mandatory:

- CE / UKCA for Europe

- FCC for the U.S.

- RoHS / REACH for environmental safety

- ISO/IEC and industry-specific standards (IEC 60601, ISO 26262, etc.)

Start early with pre-compliance testing and documentation — often the longest lead-time item in your product lifecycle.

7.Packaging, Logistics, and Post-Market Support

Final step: the “box.”

- Custom or retail packaging

- Shipping configuration and labeling (barcode, batch, region)

- Inventory tracking and returns handling

- Firmware updates, recalls, and end-of-life planning

A smart packaging and logistics strategy helps reduce shipping costs, simplify regulatory clearance, and improve customer satisfaction.

Lifecycle Management Table: From Concept to Box

| Phase | Deliverables / KPIs | Tools & Considerations |

| BOM & Design | Schematic, BOM, layout, cost targets | Altium, Octopart, lifecycle DBs |

| Prototyping | Working prototype, firmware image | 3D printing, manual test rigs |

| Component Sourcing | Approved vendors, lead time map | LCSC, Digi-Key, MOQ plans |

| Manufacturing Onboarding | EMS specs, first article pass rate | Process docs, IPC rules, NDA, logistics |

| Testing & QA | Yield rate, test coverage, debug reports | Test jigs, firmware logging, test coverage tools |

| Certification | CE/FCC docs, compliance logs | Pre-compliance labs, audit traceability |

| Logistics & Support | Product delivery, RMA process, updates | ERP integration, OTA server, packaging guidelines |

8.Common Pitfalls and How to Avoid Them

Even experienced teams can hit roadblocks during the hardware product lifecycle. Being proactive can prevent costly setbacks.

Top mistakes to watch out for:

- Incomplete BOMs: Missing alternates or lifecycle checks cause sourcing delays.

- Late DFM review: Waiting until prototype stage to think about manufacturing adds time and cost.

- Single-vendor dependency: Increases lead-time risk and weakens negotiation leverage.

- Overcomplicated test plans: Increase cost without adding value; focus on coverage, not redundancy.

- Ignoring packaging specs early: Results in rework when aligning with EMS or retailers.

Promwad’s tip:

Use a parallel validation strategy — plan BOM validation, mechanical testing, and certification paths in parallel with final prototype iterations.

Final Thoughts: A Systematic Approach Wins in Hardware

Success in embedded electronics doesn’t come from engineering talent alone. It comes from managing the full journey — from BOM to box — with foresight, tools, and trusted partners.

Promwad helps clients in automotive, industrial, medtech, and telecom sectors manage this journey end-to-end: from initial architecture to certified, boxed, and shipped devices.

Let’s build your next product the right way — from first component to final shipment.

Our Case Studies