EMS Strategy in 2025: What Tech Companies Must Know Before Outsourcing

Introduction: EMS Strategy Is No Longer Just About Cost

In the past, outsourcing to an EMS (Electronics Manufacturing Services) provider was mostly about cutting costs. But in 2025, that’s no longer enough. The right EMS strategy must also address resilience, speed, sustainability, and supply chain risk.

Whether you're a startup scaling a new device or an OEM optimizing global production, this article explores what tech companies must consider when building an EMS strategy for today's realities.

1. Diversification Is the New Rule — Not the Exception

Relying on a single manufacturing region (e.g., China) is riskier than ever due to:

- Trade policies and tariffs

- Pandemic aftershocks and logistics bottlenecks

- Rising labor and energy costs in traditional hubs

2025 Trend:

Regional EMS strategies — combining Asia + EU + North America for flexibility

Recommended approach:

- Dual-source critical SKUs with a backup EMS

- Choose partners with global footprint and multi-site capabilities

2. Certifications and Compliance Matter More Than Ever

If you're in automotive, medtech, energy, or industrial sectors, your EMS partner must demonstrate:

- ISO 13485, IATF 16949, or ISO 26262 familiarity

- Traceability and QMS documentation

- RoHS, REACH, and conflict mineral declarations

2025 Tip: Treat compliance as a competitive advantage. It reduces delays, lowers risk, and supports faster product launches.

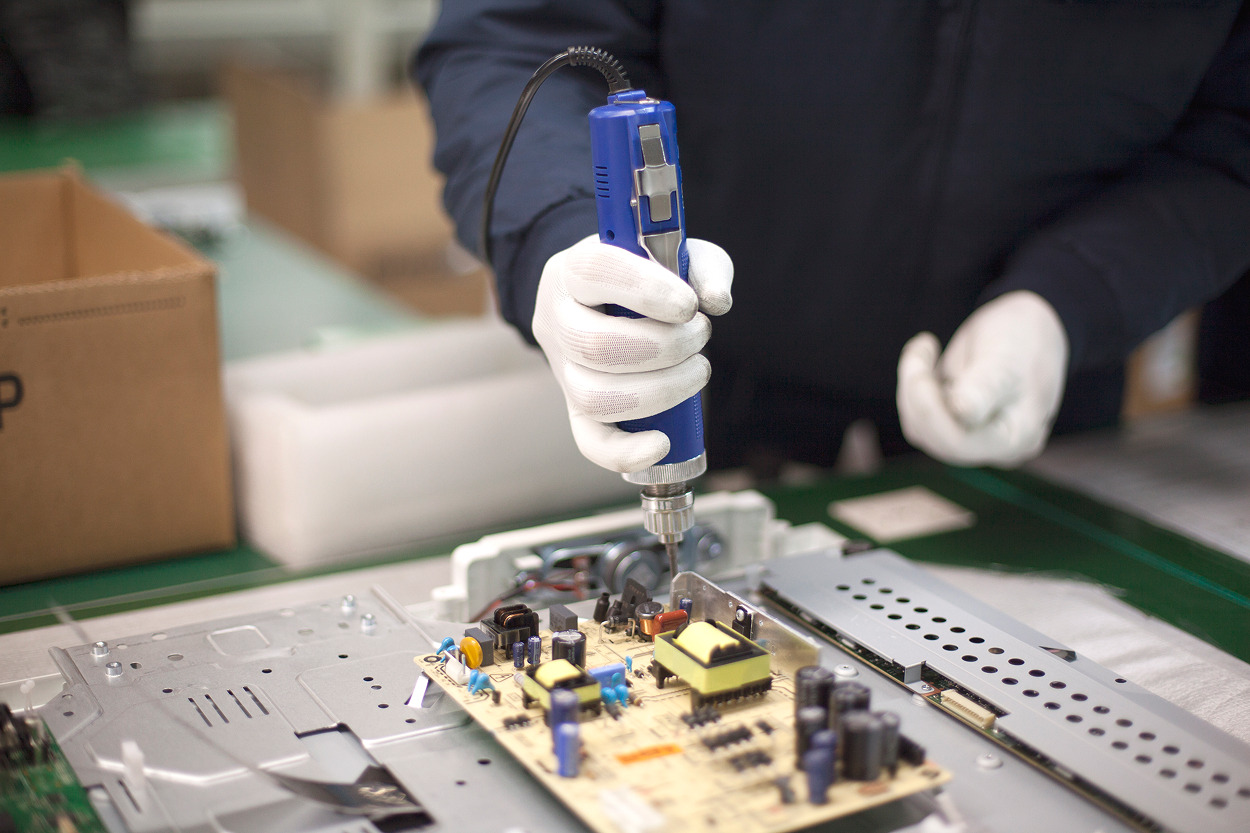

3. Engineering Support and Co-Development Are Essential

Modern EMS partners offer more than assembly — they provide:

- DFM (Design for Manufacturing) feedback

- Test development and fixture design

- Component substitution and sourcing strategy

What to look for:

- Dedicated NPI (New Product Introduction) teams

- Ability to support custom test strategy and firmware flashing

- Early engagement during prototype iterations

Promwad often works alongside EMS providers to bridge design and production — improving yield, simplifying tests, and reducing ramp-up time.

4. Transparency in Pricing and Forecasting

Unclear cost structures can derail growth. In 2025, it’s critical to have:

- Clear breakdowns of NRE (non-recurring engineering), tooling, and setup fees

- BOM pricing and sourcing visibility

- Flexibility to adapt to demand changes or EOL components

Tools to consider:

- PLM systems integrated with EMS BOM management

- Real-time supply chain dashboards or portals

5. Sustainability and ESG in Manufacturing

Electronics brands now face increasing pressure from regulators and customers to prove:

- Low environmental impact (carbon footprint, energy efficiency)

- Ethical labor practices in their supply chain

- Material sourcing transparency

How your EMS fits in:

- Ask for ESG reports and recyclability metrics

- Prioritize partners with green certifications and energy-efficient plants

Table: EMS Partner Checklist for 2025

| Category | What to Look For |

| Technical Capabilities | DFM, test jigs, firmware flashing, traceability |

| Regional Footprint | Multi-site manufacturing, local + offshore options |

| Certifications | ISO 9001, 13485, IATF 16949, IPC-A-610, RoHS |

| Communication | Account manager, shared project dashboards |

| Pricing Model | Transparent quotes, dynamic BOM sourcing |

| Sustainability | ESG practices, waste reduction, energy metrics |

6. Case Study: Scaling Production of an Industrial IoT Device

A European OEM developing industrial gateways approached Promwad to help transition from small-batch prototyping to EMS-driven volume production.

Challenge:

- BOM had several EOL components

- Initial design lacked DFM optimizations for SMT automation

- Regulatory certification required test traceability and documentation

Our contribution:

- Revised PCB layout and component selection for EMS compatibility

- Co-developed functional test jig and firmware flashing setup

- Provided EMS partner shortlist based on region, certification, and yield

Results:

- Reduced manufacturing cost per unit by 18%

- Passed CE and FCC tests without redesigns

- Scaled production from 100 to 10,000+ units within 6 months

Final Thoughts: EMS Is Now a Strategic Asset

In 2025, your EMS provider isn’t just a vendor — it’s a core part of your product delivery strategy. Choosing the right partner can reduce delays, improve quality, and give your product the agility it needs to succeed.

Promwad helps OEMs and tech startups prepare for EMS engagement — from DFM and compliance planning to EMS onboarding and production ramp-up.

Let’s build a smart, future-ready manufacturing strategy for your electronics project.

Our Case Studies in Electronics Manufacturing