Smart Electronics for Tail Lifts: ECUs, Wireless Controls & IoT Integration

Manufacturers of vehicle lift systems — from rear-mounted tail lifts to retractable and column-based platforms — face increasing pressure to modernize their electronics. They must reduce system complexity and costs, integrate wireless control, and enable remote diagnostics, all while ensuring safety and ruggedness under harsh road conditions. Equally important is compliance with automotive standards, such as IP67 ingress protection, EMC (CE/FCC), ISO 26262 functional safety, and AEC-Q component qualification.

With extensive experience in embedded software, RF design, and IoT systems, Promwad enables OEMs to deliver robust, intelligent, and certifiable electronics tailored specifically for harsh automotive environments.

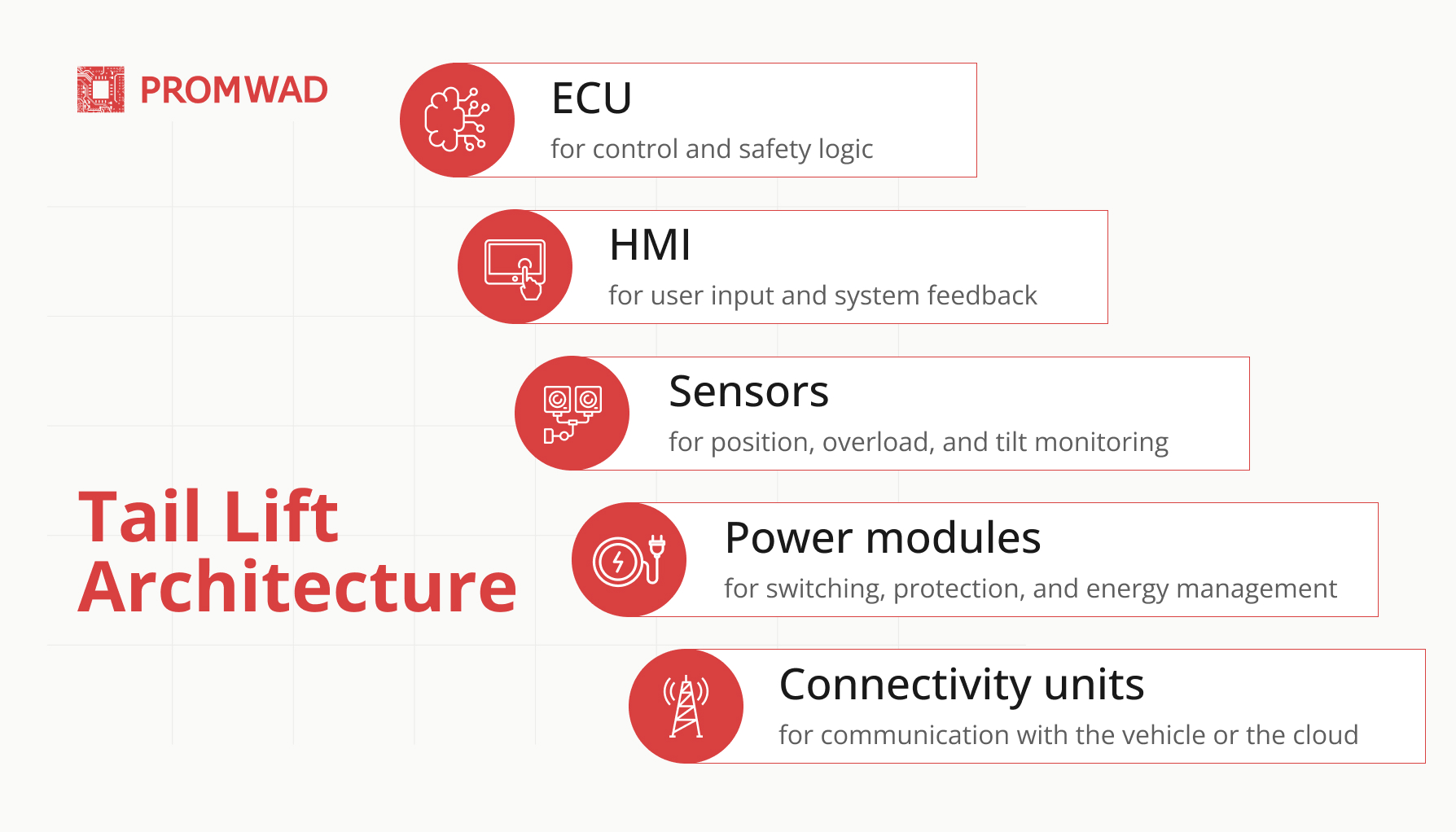

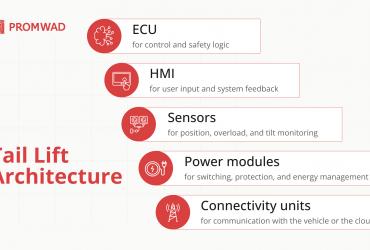

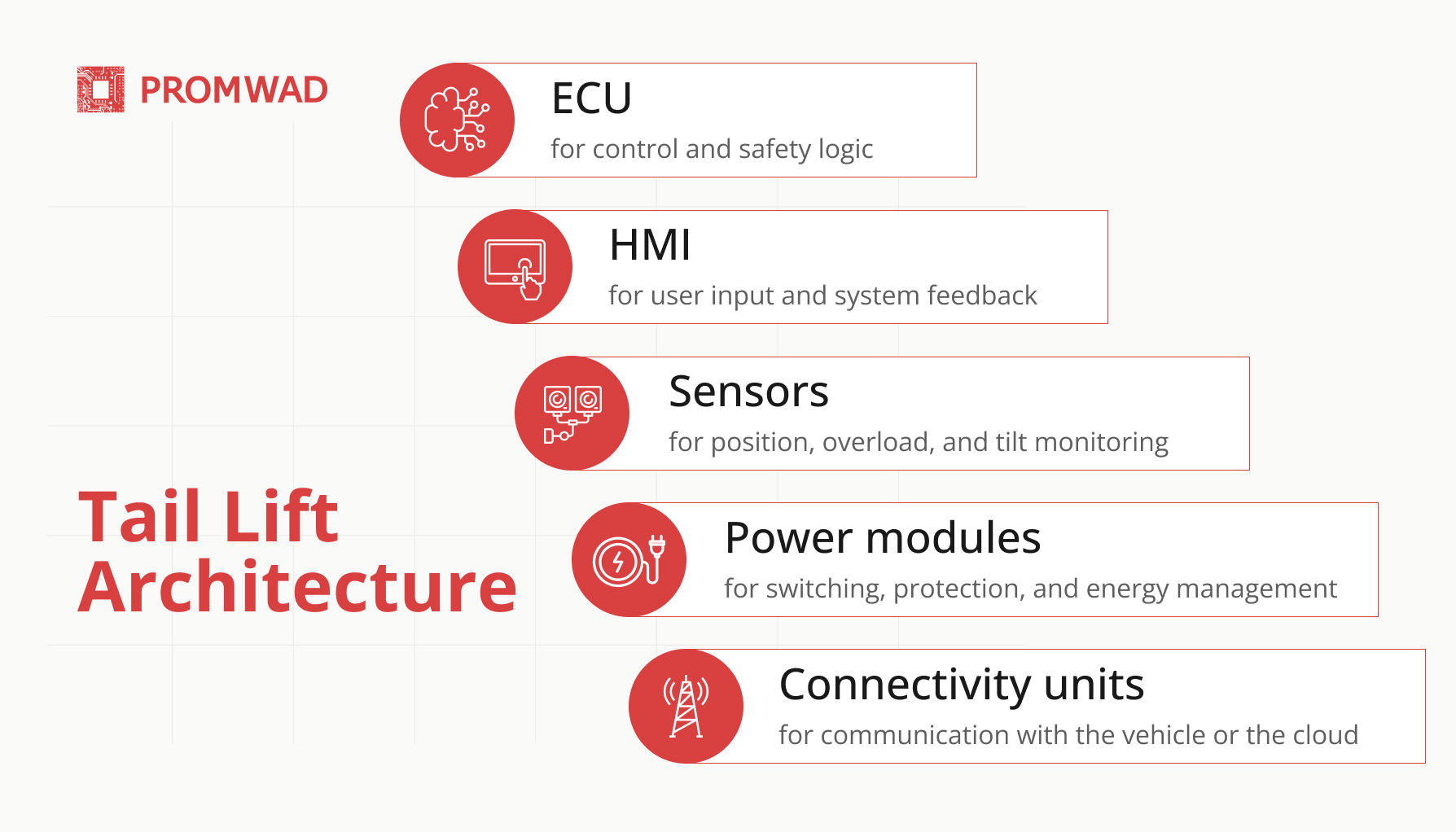

Tail Lift Architecture

Modern vehicle lift systems require a combination of rugged hardware, intelligent control, and seamless connectivity. A typical electronic architecture includes the following key components:

At Promwad, we have the engineering expertise to develop each of these modules. Below, we explain how our experience applies to every part of the system.

Electronic Control Units

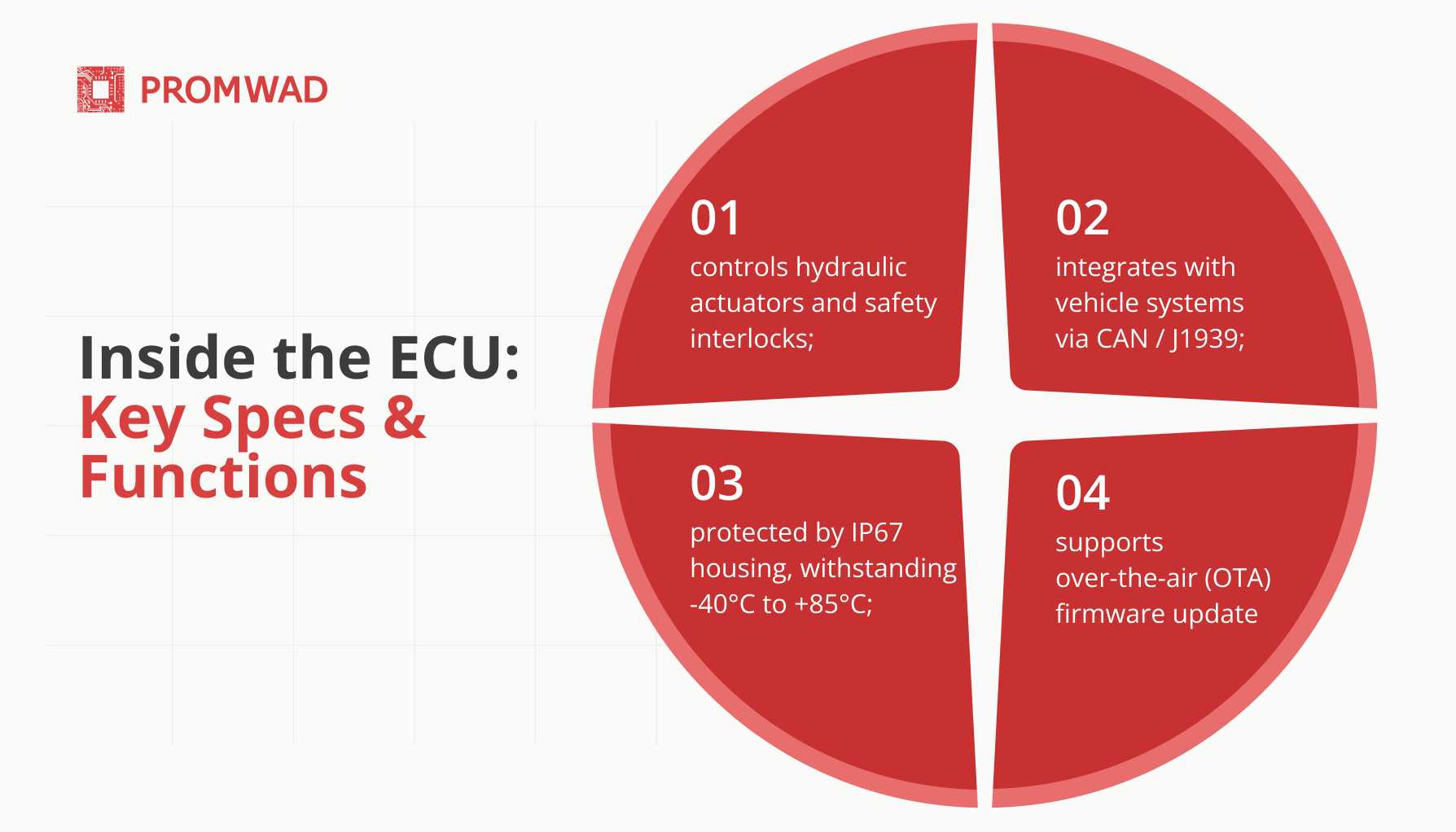

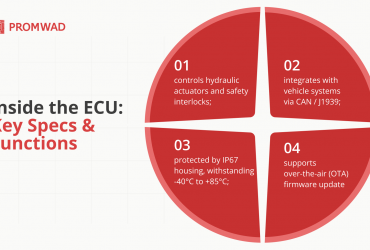

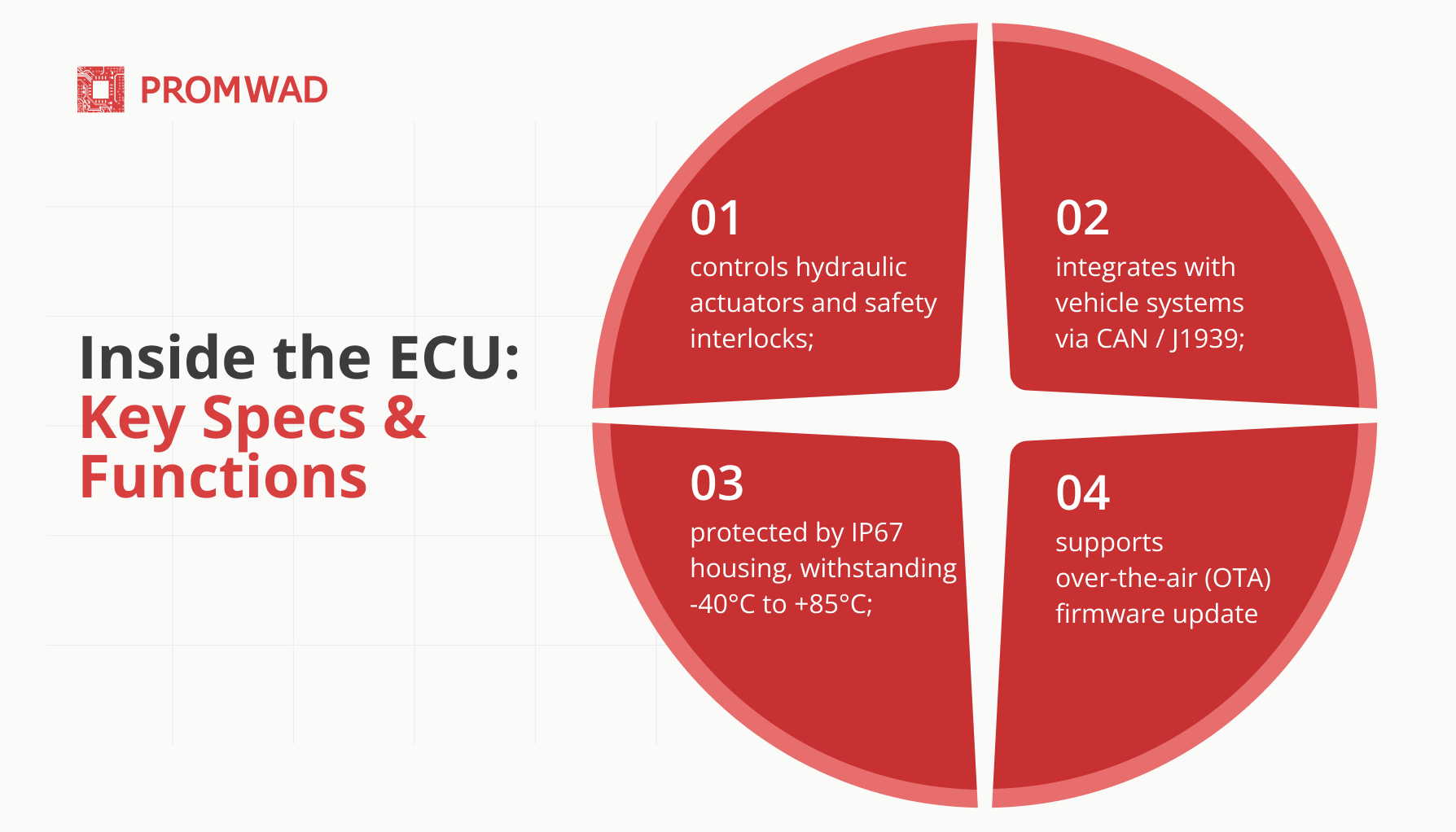

The ECU is the central controller responsible for executing system logic, ensuring safety, and maintaining reliable communication between lift components and the vehicle’s main control network. It performs the following functions:

We develop custom ECUs with embedded software and diagnostic features tailored to harsh environments and optimized for cost and certification.

Our ECUs are based on real-time operating systems (RTOS) to ensure fast and deterministic control. We also implement CAN and LIN communication stacks to support seamless integration with the vehicle’s electronic architecture.

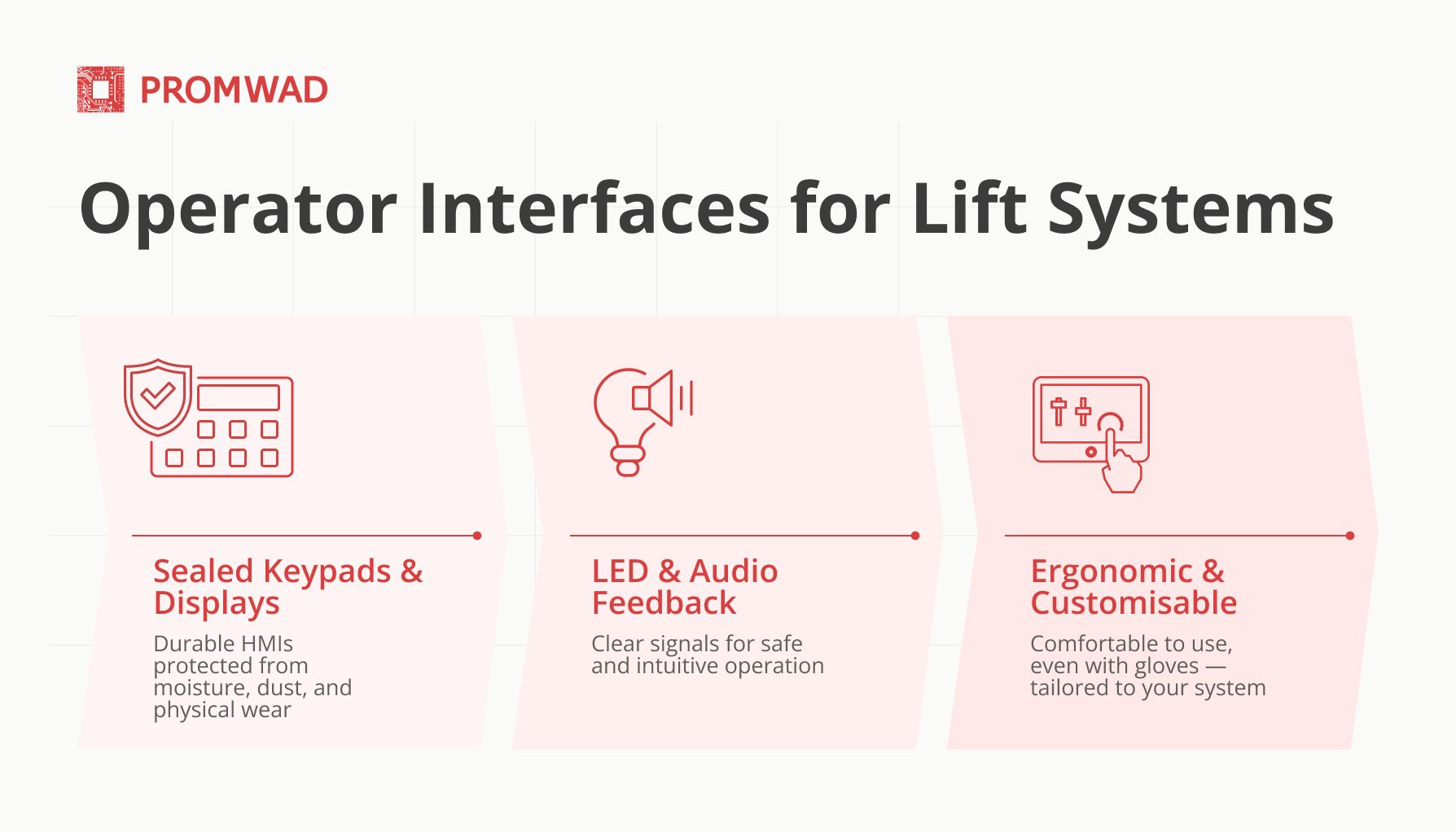

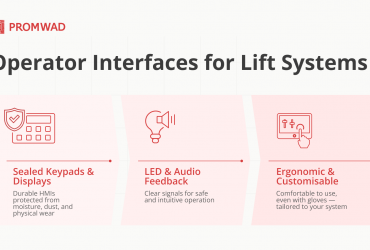

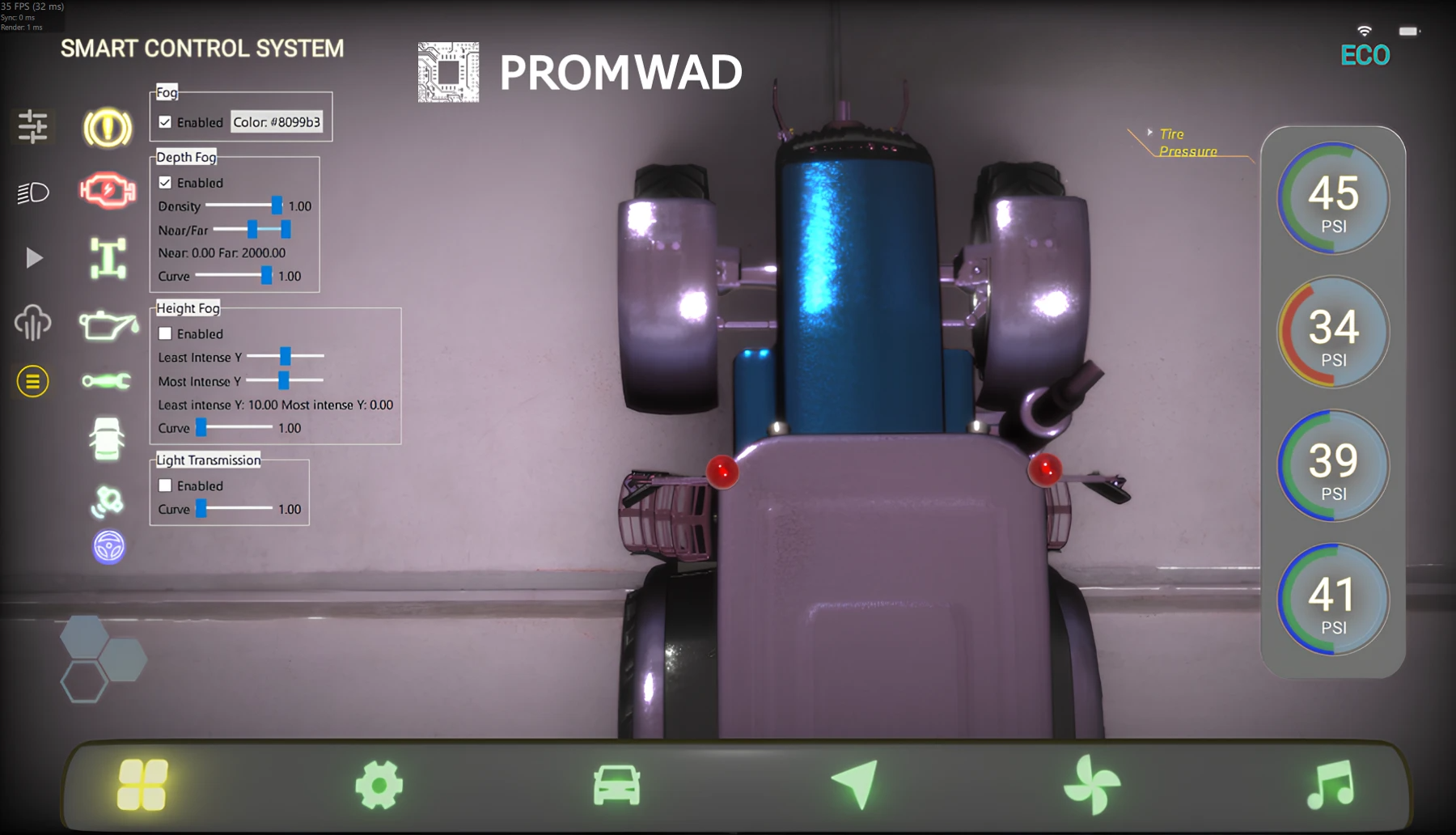

Operator Interfaces

For lift systems used outdoors operator interfaces must remain reliable in any weather, intuitive for daily use, and protected from physical damage:

- fully sealed keypads or compact HMI displays;

- LED indicators and buzzer feedback;

- ergonomic design and customization options.

At Promwad, we design and engineer sealed human-machine interfaces (HMIs) that combine durability with clear feedback and ergonomic layout. Our solutions are adapted from experience in industrial and agricultural equipment, where visibility, glove-friendly controls, and resistance to dust and moisture are critical.

Case study: development of an HMI interface for the agricultural industry

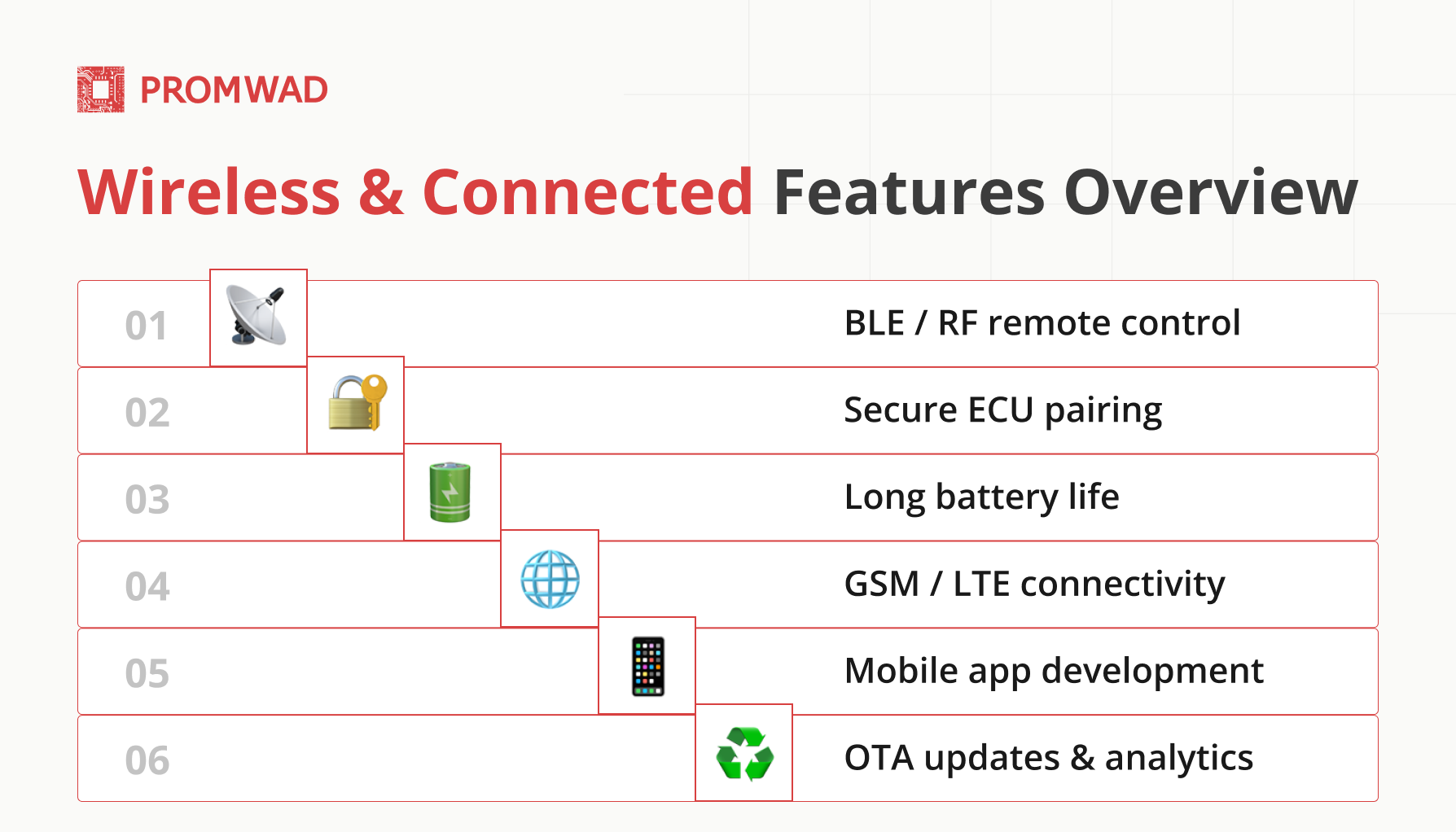

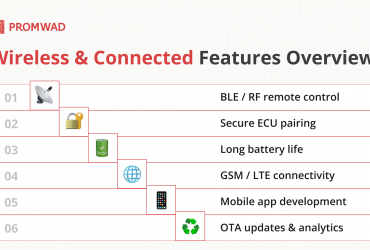

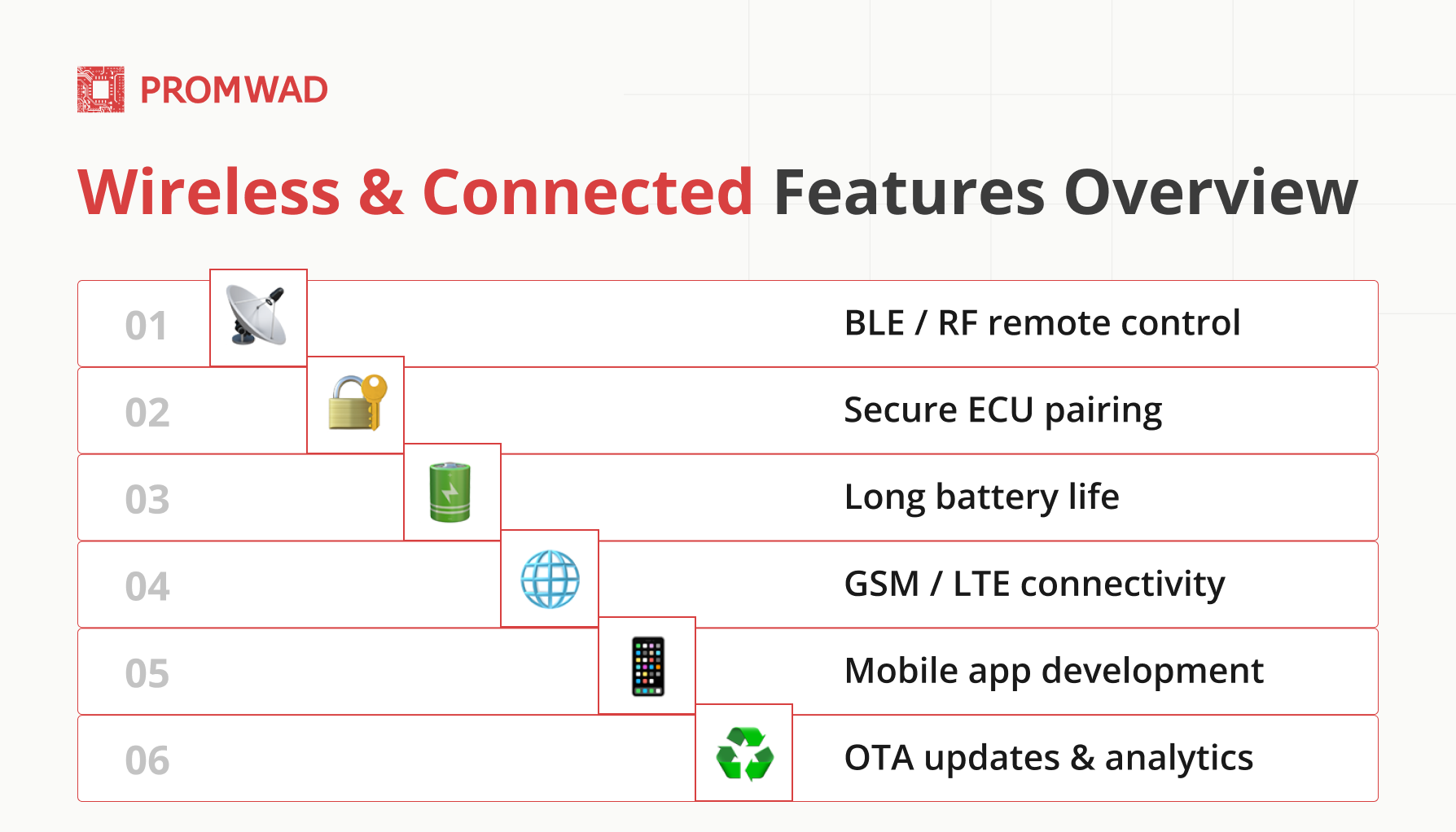

Wireless Control & Connectivity

Wireless and connected features are essential for the next generation of tail lifts. They improve operator safety, simplify in-cab wiring, and enable remote diagnostics and fleet monitoring. Promwad provides full-stack development — from embedded BLE modules to cloud dashboards and mobile apps:

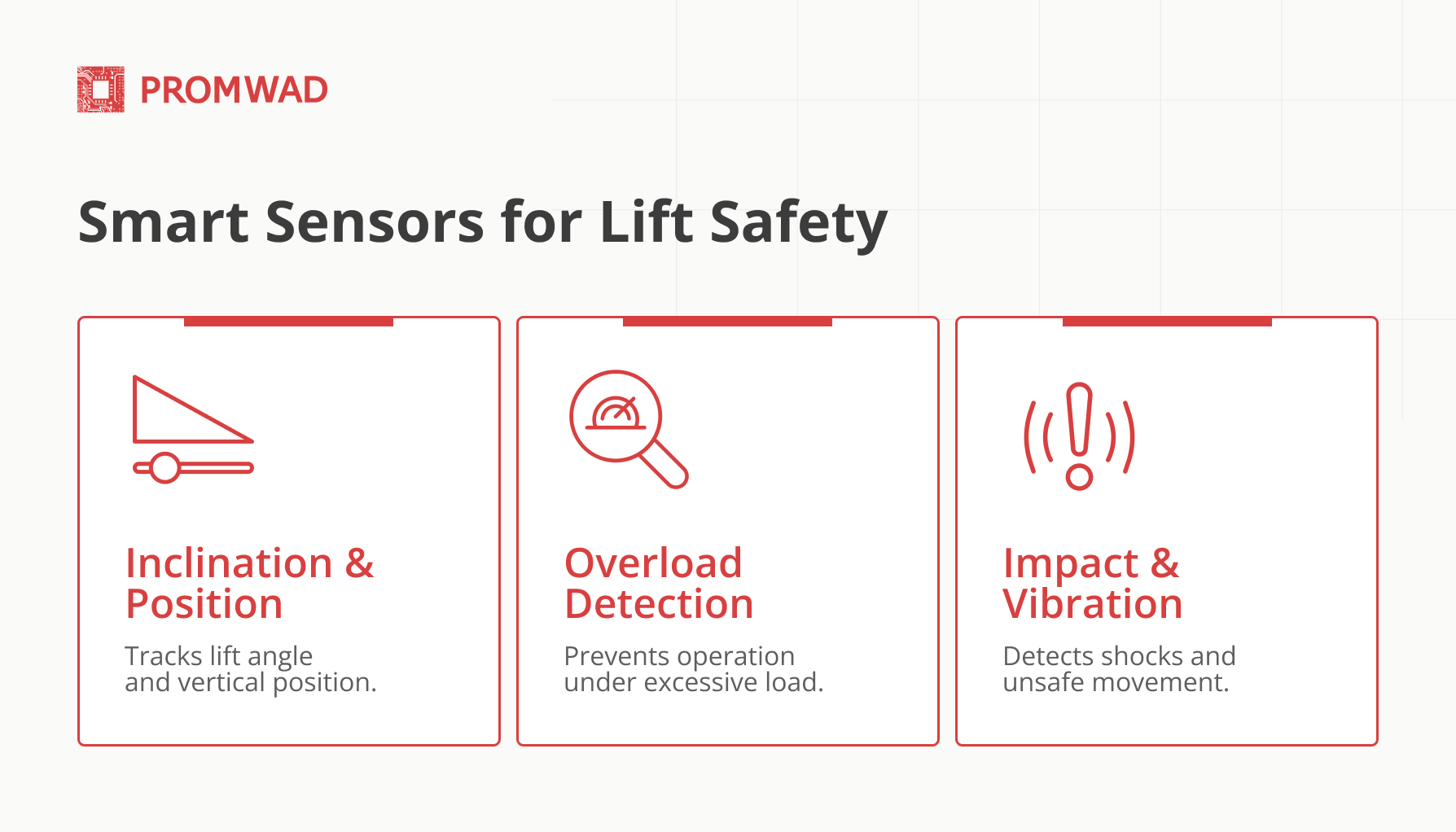

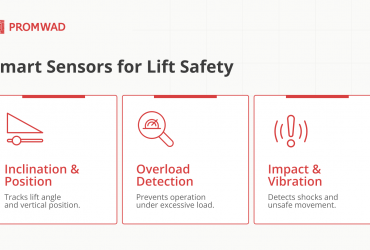

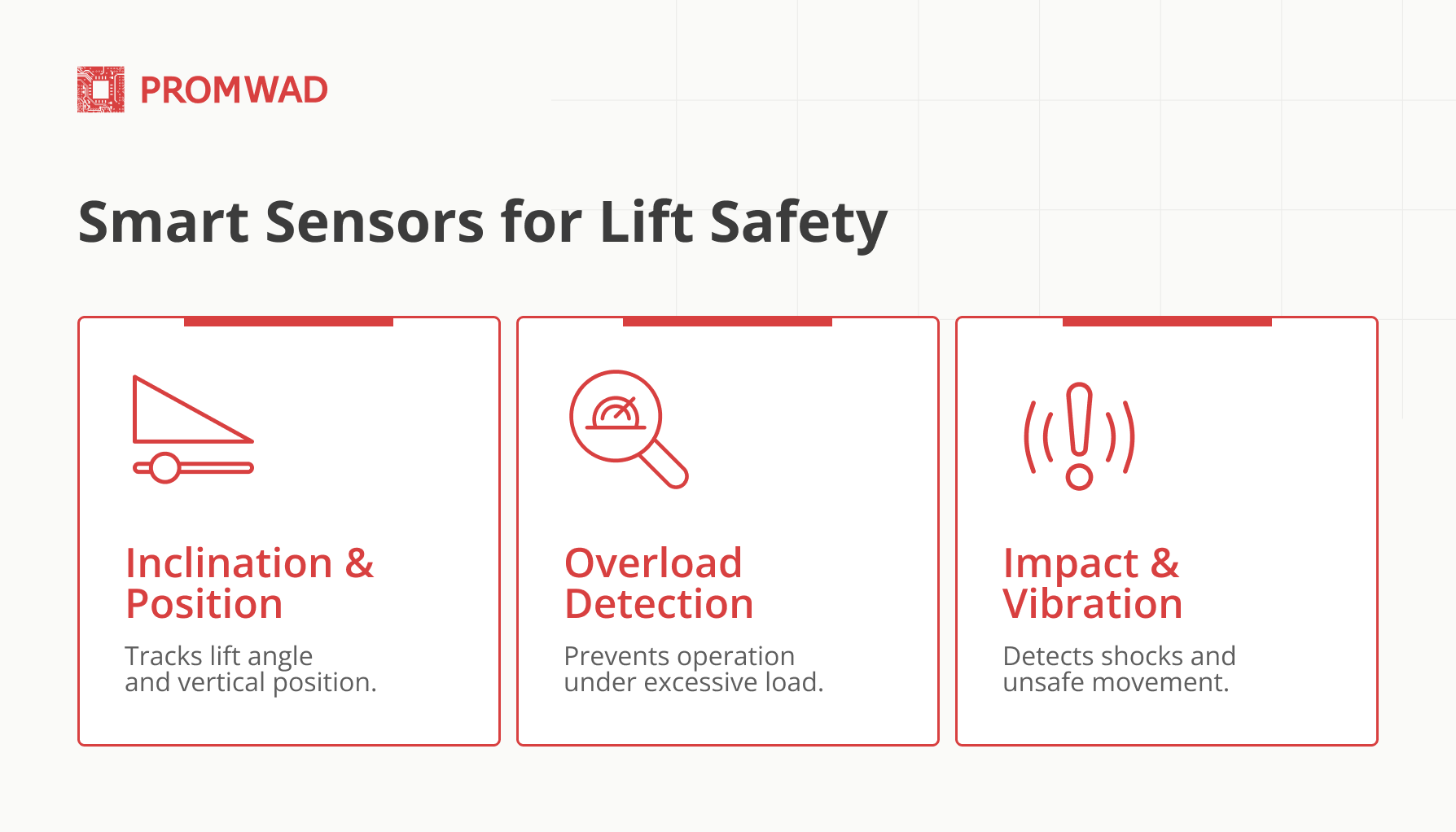

Sensor Systems & Safety Logic

Smart tail lifts require integrated safety systems that detect potentially dangerous conditions. These systems enable preventive maintenance, reduce downtime, and protect both equipment and operators. Promwad develops sensor modules and interface logic (analog or CAN-based) for seamless integration into the lift control system.

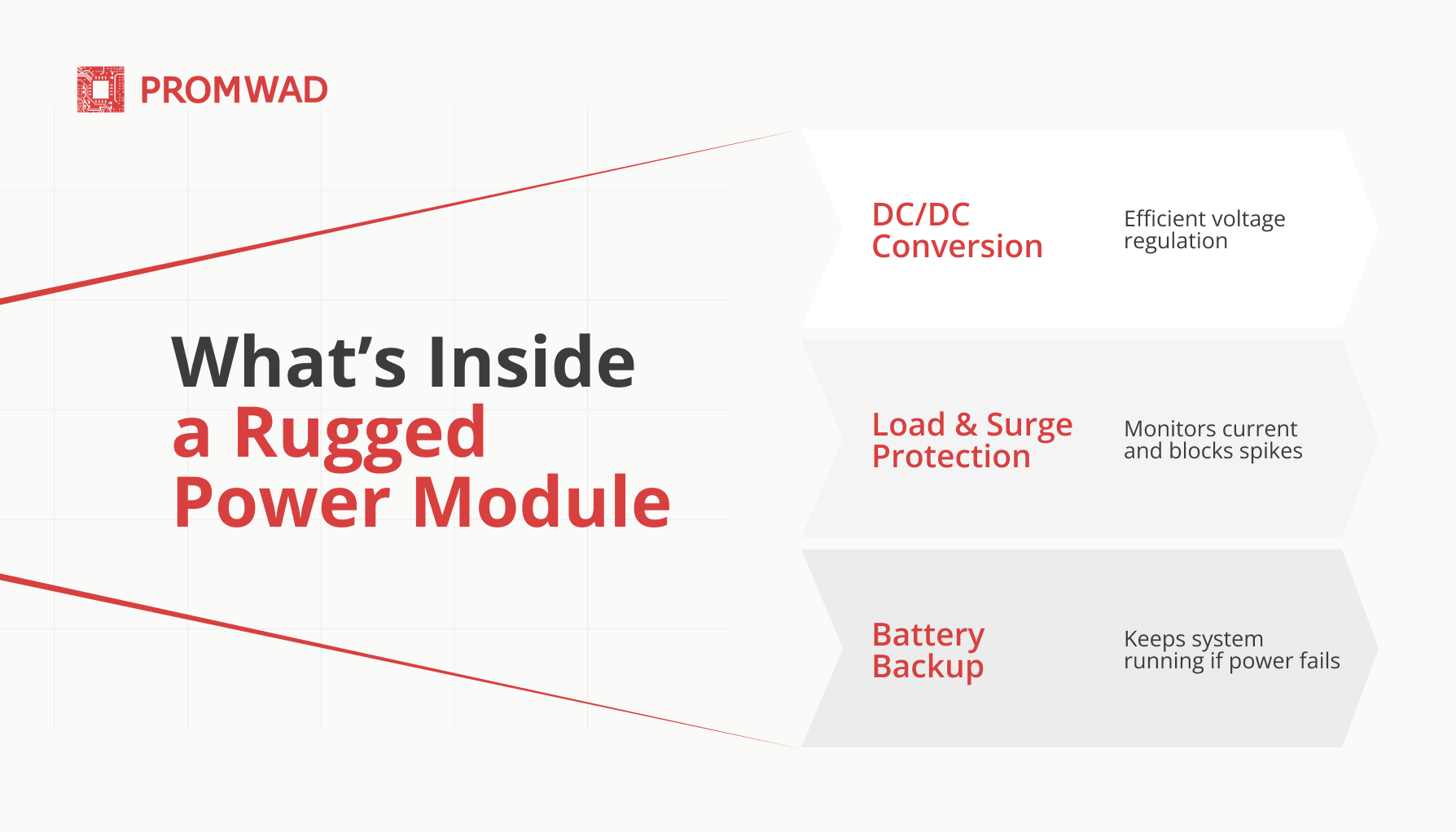

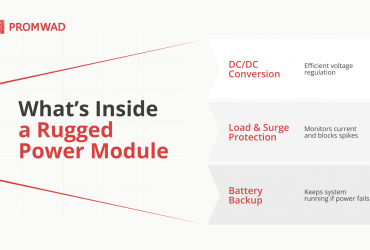

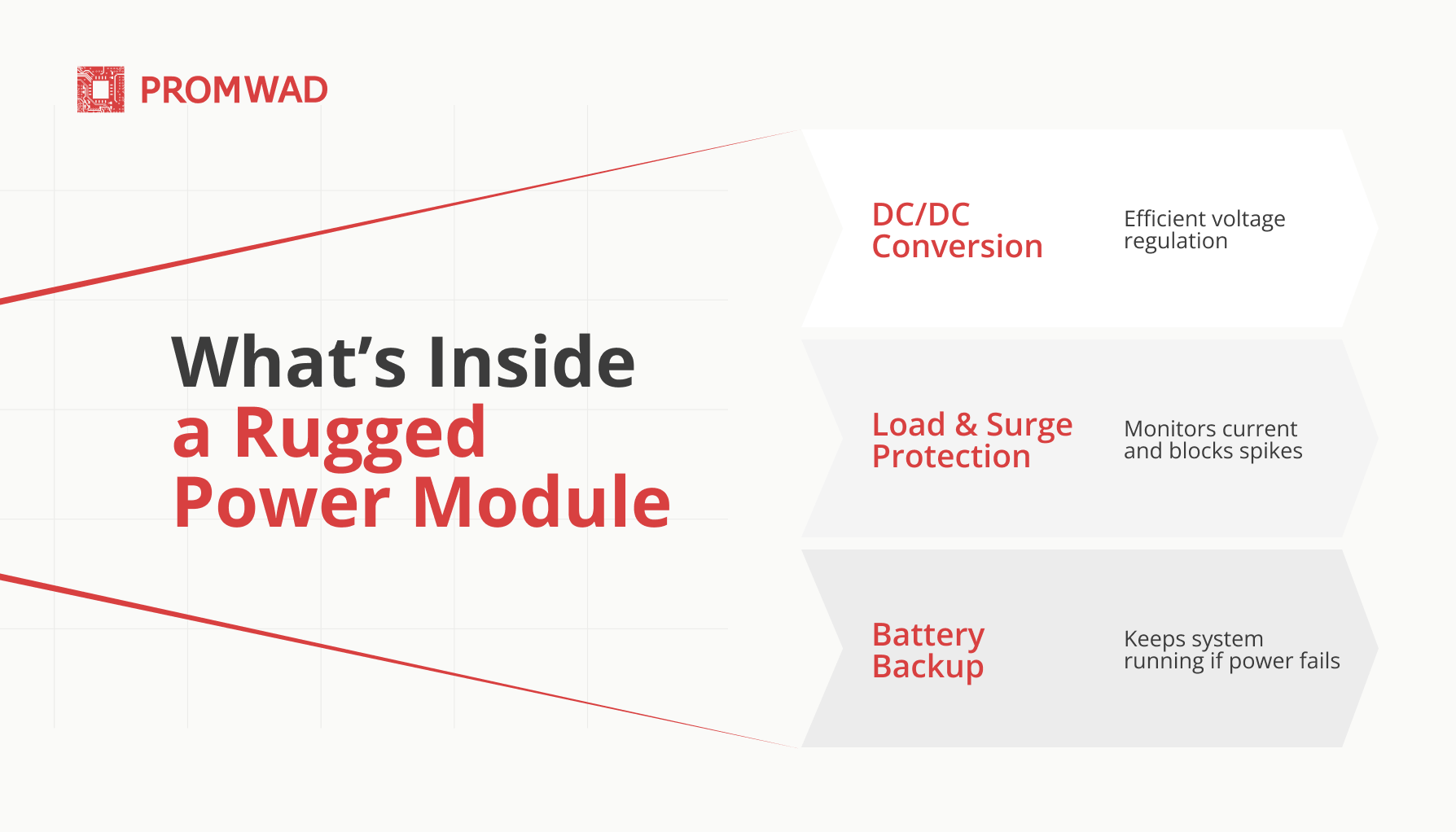

Power & Switching Units

A robust power system ensures safe and reliable lift operation even under unstable electrical conditions. We design modules that handle switching, energy buffering, and protection.

We design rugged power modules for tail lifts, drawing on our experience with off-road and industrial vehicles to ensure reliable performance in harsh electrical conditions.

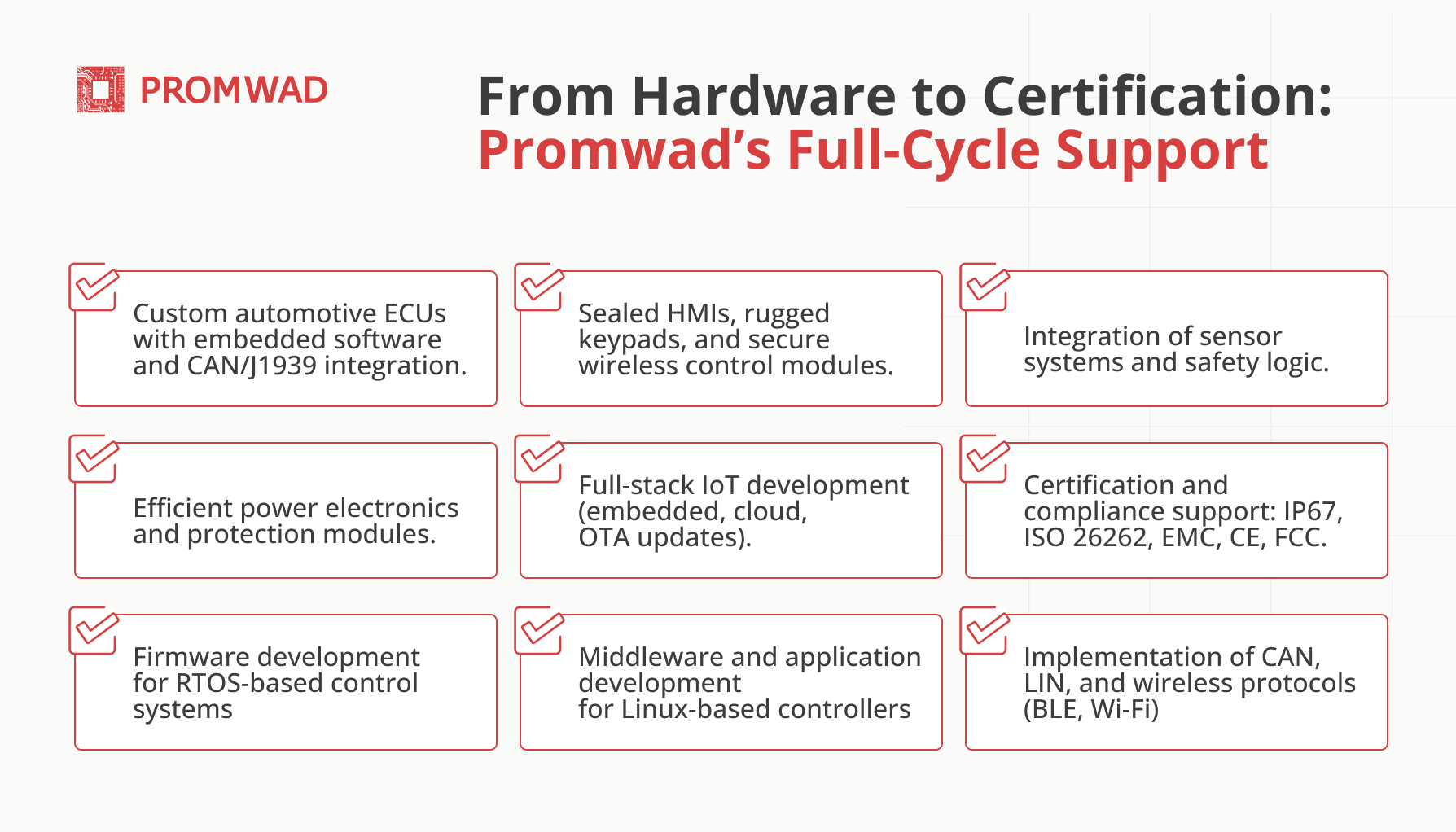

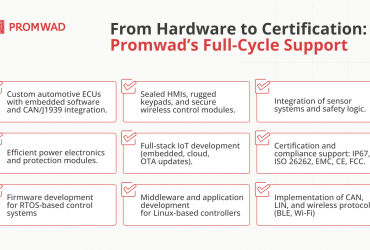

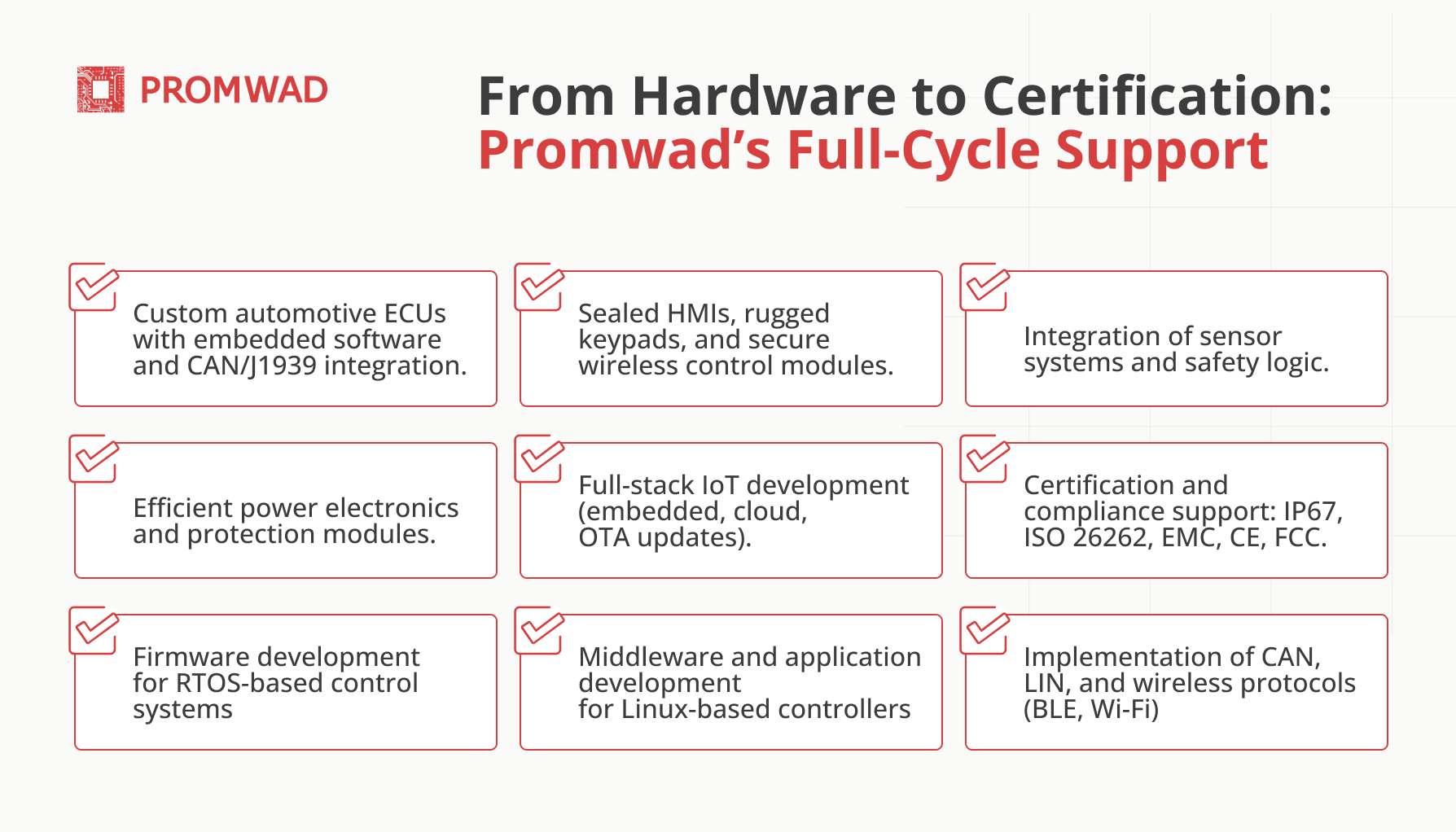

Full-Cycle Engineering Support from Promwad

Promwad provides comprehensive engineering services tailored to your product strategy and market goals:

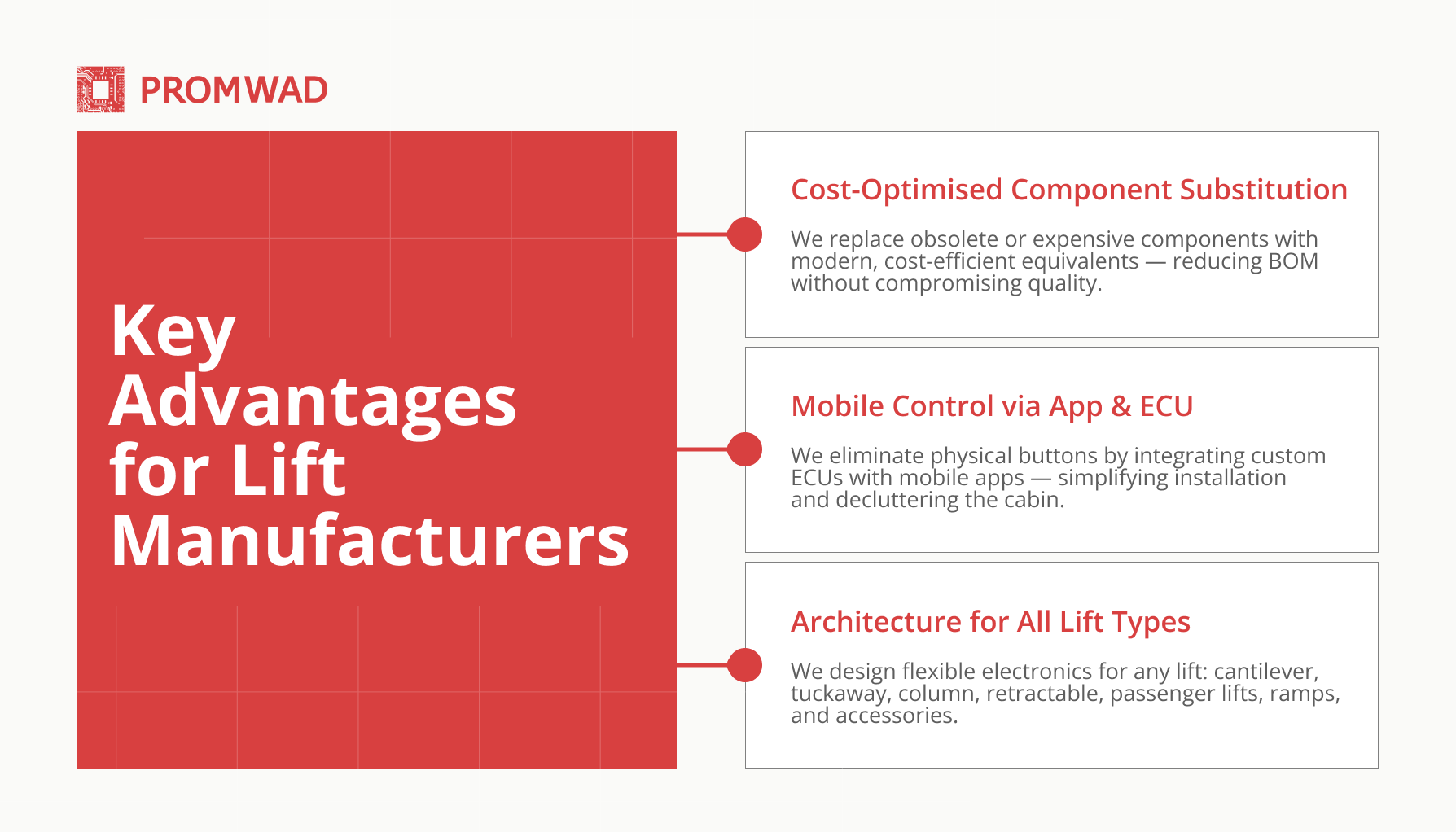

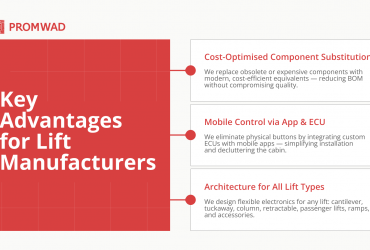

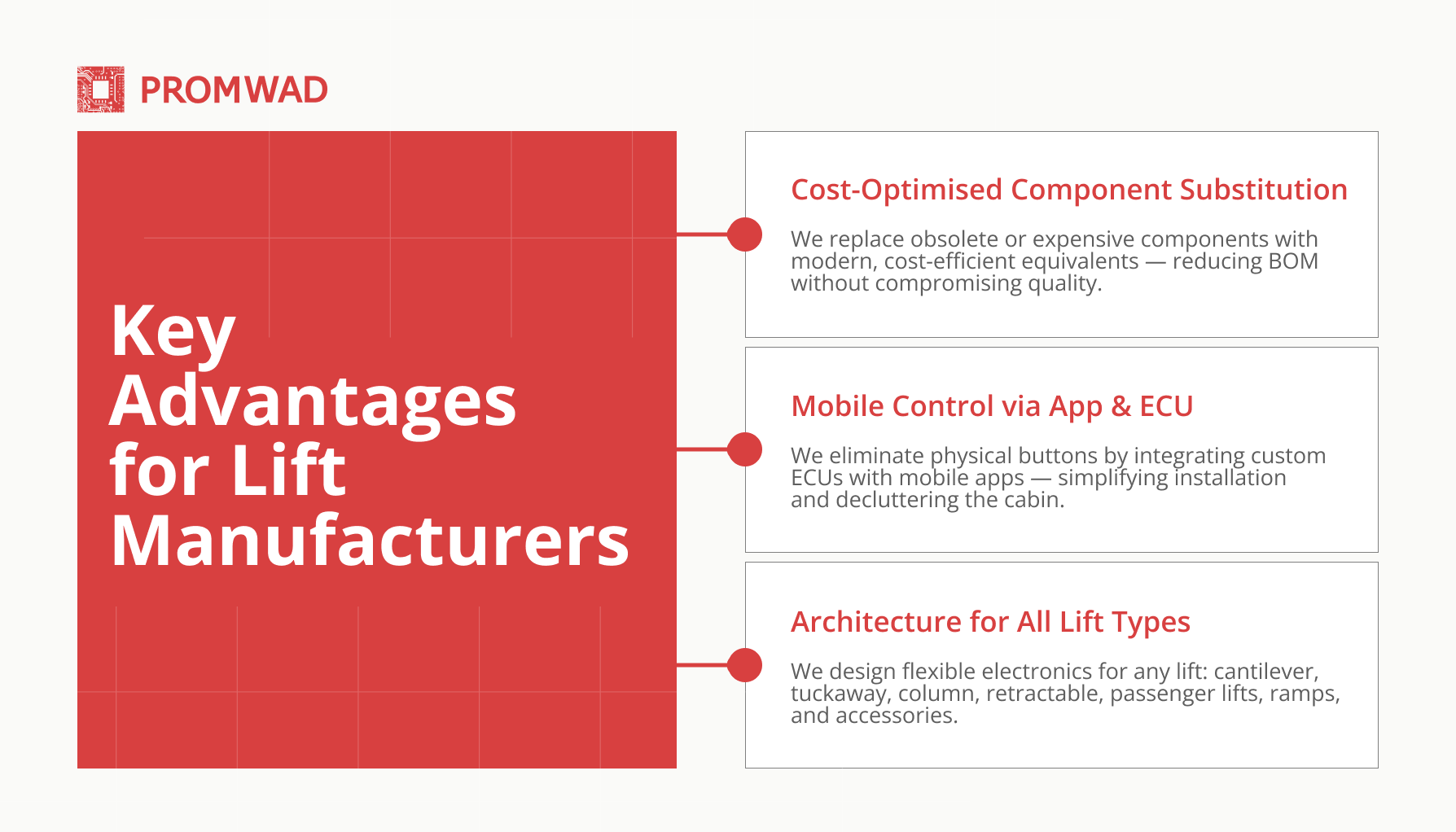

Tailored Value for OEMs

We support both new product development and the modernization of existing systems. Whether you're upgrading outdated electronics or launching a new smart lift, we adapt to your business goals.

Looking to modernize your tail lift controls?

We’re ready to bring your system to life!