Enclosures Design of Radiation Control and Detection Instruments

Project in Nutshell: We designed enclosures for a new product line from one of the leading manufacturers of radiation detection and control equipment, solving three other problems: protection against supply chain disruptions, the ability to use sensors from two different suppliers, and to charge from different types of batteries.

Client & Challenge

Our client's solutions are used in nuclear power plants, border guards, emergency response and other areas where radiation monitoring is crucial.

Previously, we updated a case of a professional dosimeter for this client, and in the new project, we joined the development of a series of radiation detectors: spectroscopic personal radiation detector (SPRD) and radioisotope identification device (RIID).

Solution

The Promwad team started conceptualising enclosures for two devices:

- SPRD is a wearable tool for constantly monitoring radiation levels in the environment.

- RIID is a device that identifies different types of radioactive materials and their places of origin.

The project was arranged in such a way that our client focused on electronics development while Promwad concentrated on design and construction. For this purpose, we formed a team of two designers, an industrial designer and a project manager.

SPRD: enclosure and mechanical design

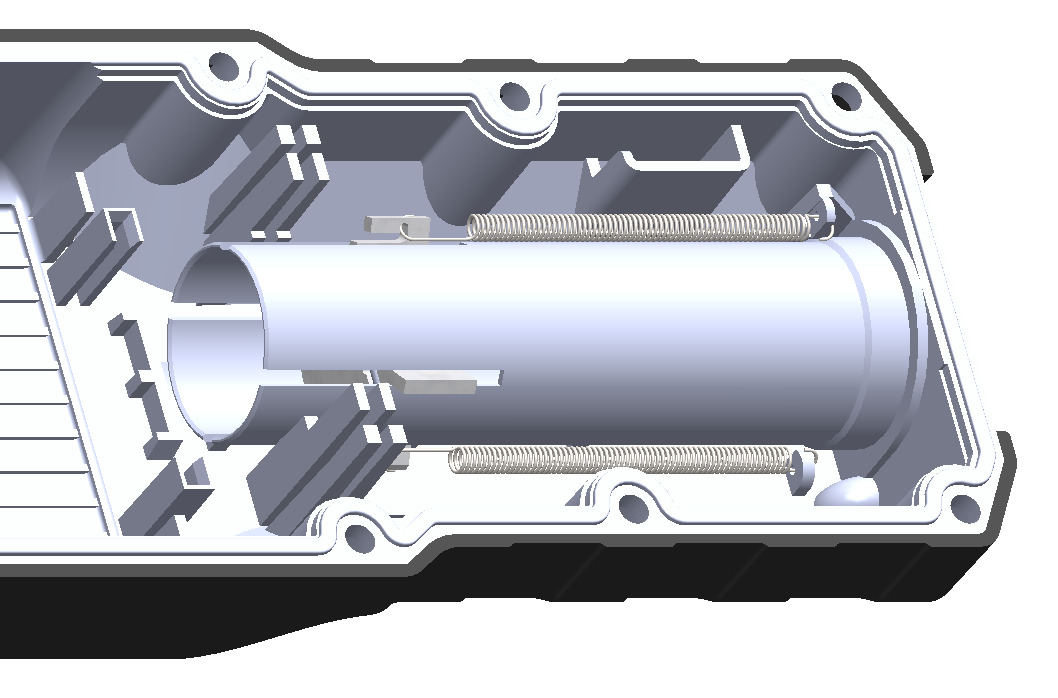

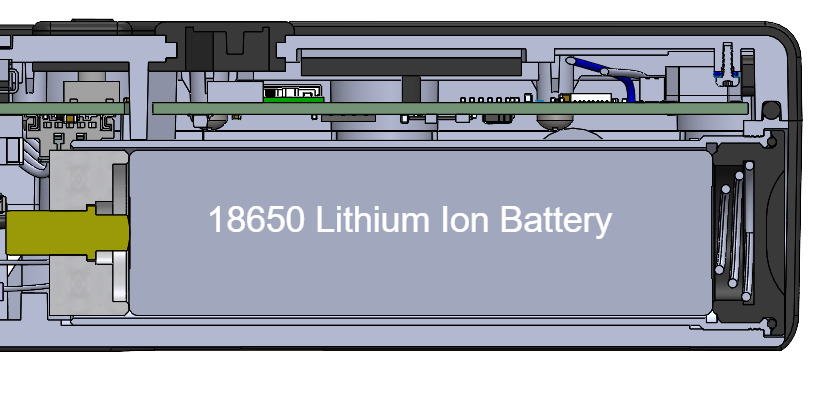

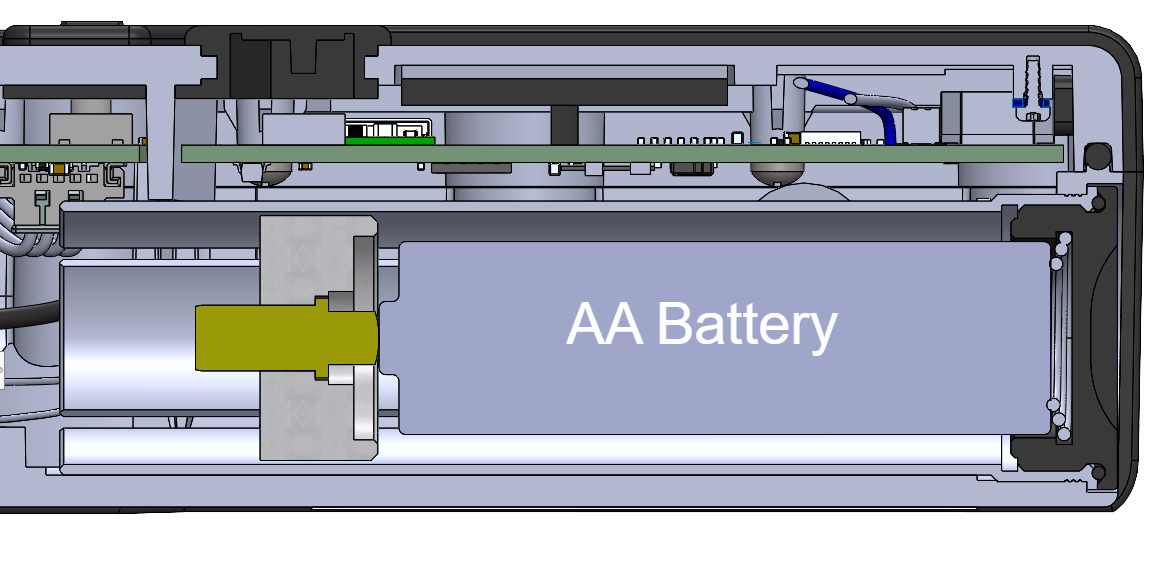

When designing the enclosure, we included the possibility of operating from two types of batteries with different sizes:

- the 18650 battery — 18 x 65 mm;

- the AA battery — 14.5 x 50.5 mm.

Implementation of a battery compartment in SPRD for two types of batteries with different sizes

We came up with a solution where the battery compartment securely holds both types of batteries without increasing the device's overall size. To do this, we used a spring-loaded sliding contact that changes the interior space of the compartment for each battery type:

The battery compartment is also designed with a pogo pin, a spring-loaded pin for reliable electrical contact in case of minor changes in battery size or location.

The batteries are secured in the compartment with a screw cap with a 1.77 mm pass so that it can be opened or closed with a 20 US cent coin.

The Promwad designers also solved the problem of the battery pack's stability. After the first iteration, it became clear that the battery compartment was shaky and could be damaged if the device was dropped. We added support elements to fix the battery and ensure smooth device operation.

3D model of the designed SPRD

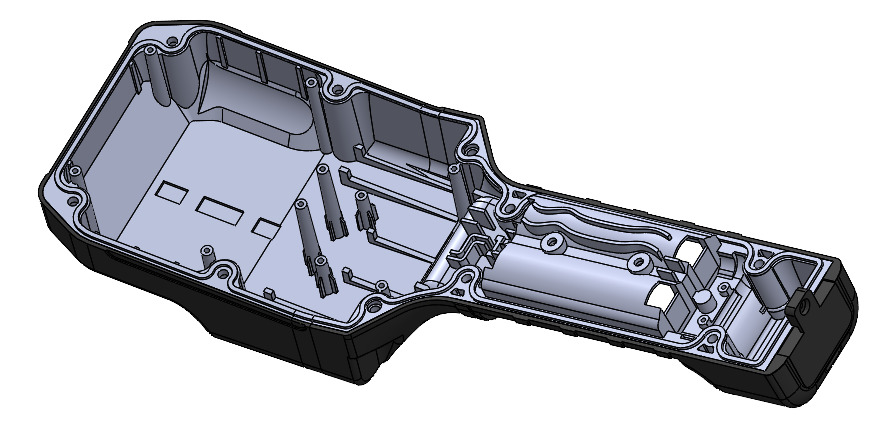

RIID: enclosure and mechanical design

The second device the Promwad team worked on was an RIID that determined the type and origin of radioactive materials.

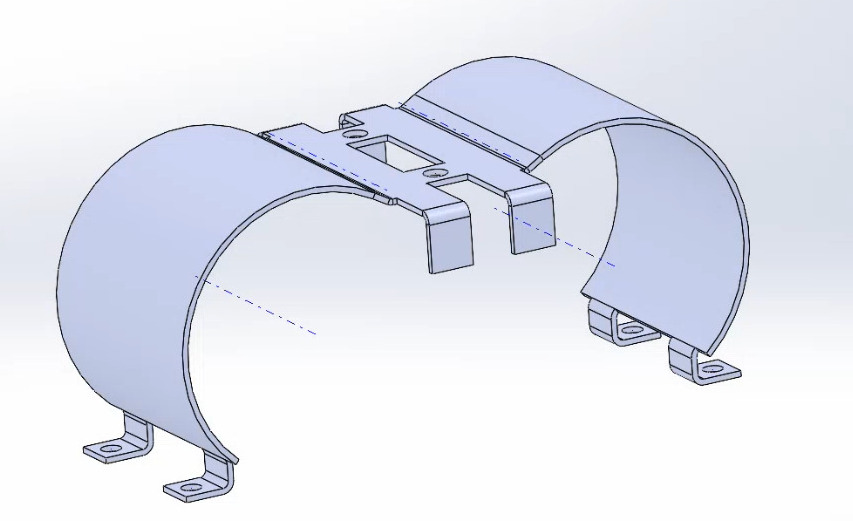

When designing the RIID enclosure, we considered that one of the sensors could be cylindrical or rectangular. Since both shapes fulfil the same function, the project team designed an adaptable enclosure that allows for easy sensor replacement.

The bottom of the enclosure was designed to hold the interchangeable set of cylindrical sensors securely. Special cut-outs ensured their stability and prevented them from moving inside the enclosure.

Lower part of the RIID enclosure with undercuts for stability of cylindrical sensors

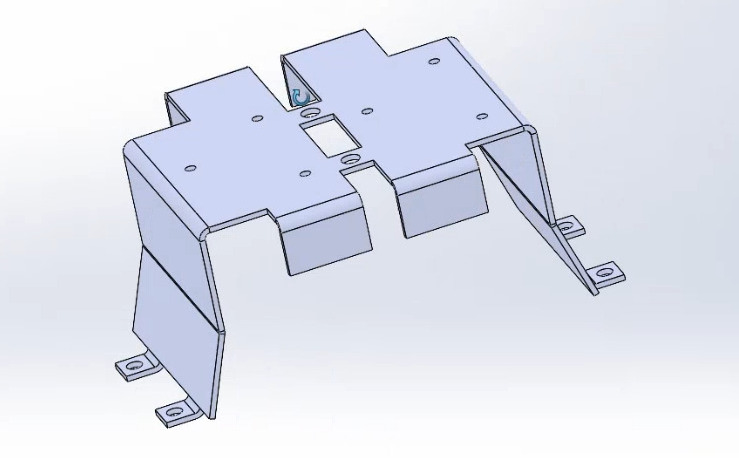

Both types of sensors — cylindrical and rectangular ones — are mounted with special brackets:

Mounting bracket for cylindrical RIID sensors

Mounting bracket for rectangular RIID sensors

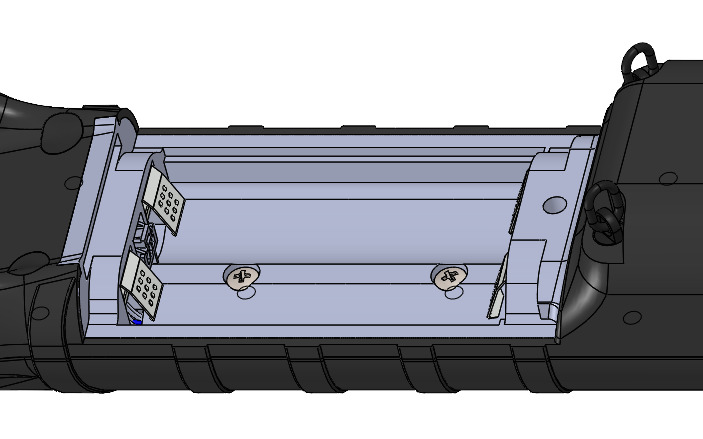

The RIID is powered by two types of batteries, so we designed the battery compartment to be able to charge from:

- two 18650 cylindrical batteries connected using traditional contacts;

- three AAA batteries.

Implementation of a battery compartment in the RIID for 18650 and AAA batteries

To use the 9-volt battery as an alternative power source, we installed an additional connector and adjusted the battery compartment to hold both types of batteries securely.

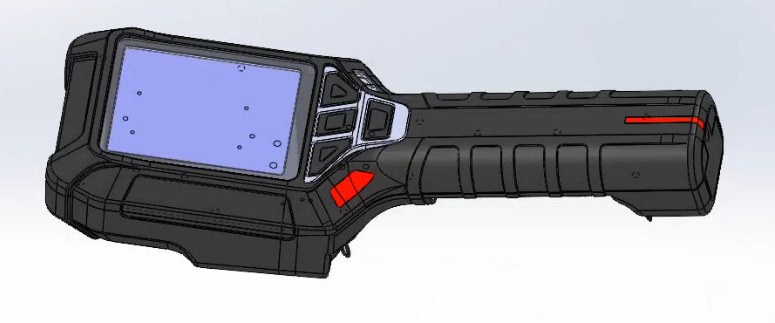

3D model of the designed RIID

We have placed three indicator lights on the RIID device: two on the front of the enclosure and one on its handle, where it can be seen from above when the device is hanging on a belt or lanyard.

Location of indicator lights on the RIID device

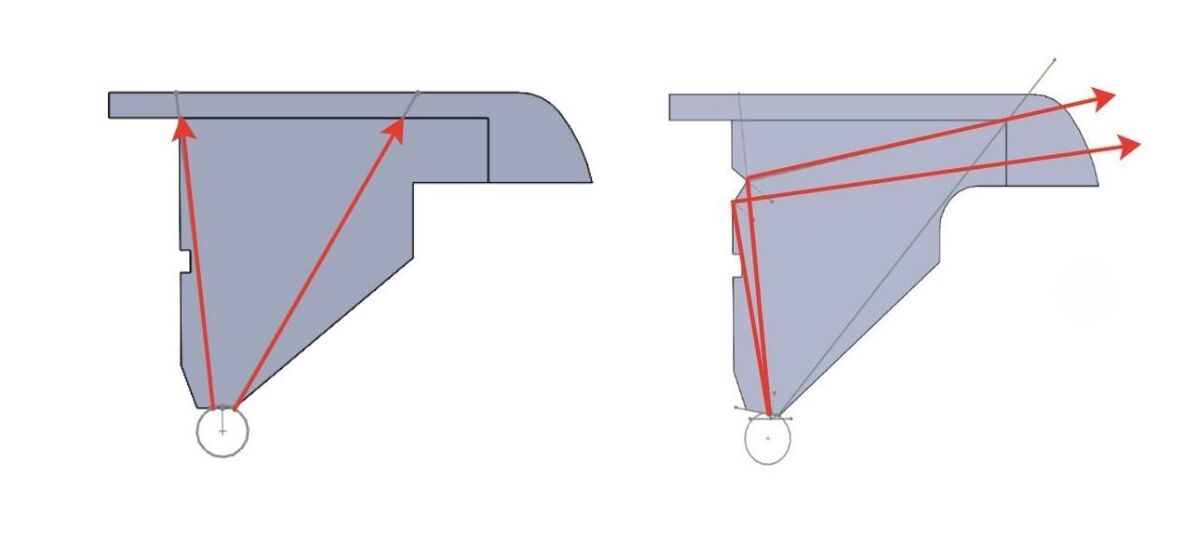

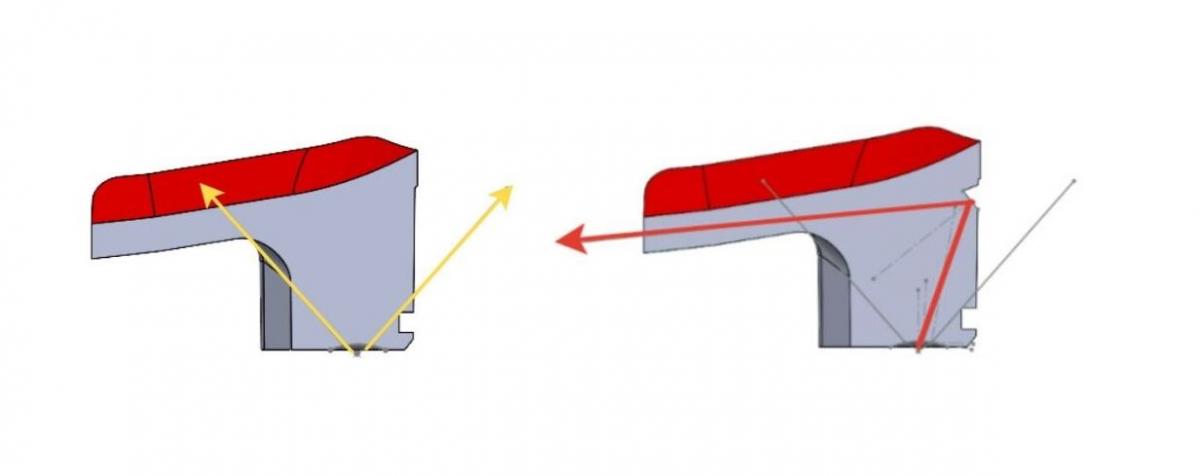

After testing the first sample, our industrial designers found that the indicator light on the handle was not hitting the right spot, and the light beam in the front panel was not distributed across the entire surface. To solve this problem, we made cutouts in the light guide and created additional planes that helped reflect the light beams to the correct points:

Trajectory of light rays before and after adding a new plane for reflection in the indicator on the device handle

Trajectory of light rays before and after adding a new plane for reflection on the "front" light indicator

The prototypes of the device enclosures were made by 3D milling, while the batch of finished enclosures will be produced by injection moulding. This involves the creation of a solid plastic base and adding a rubberised overmoulding layer to improve grip and protect the device in the event of a fall. This combination of materials will ensure the durability and usability of the devices.

Business Value

Our client has received debugged prototypes and design documentation for their new range of SPRDs and RIIDs. Both are lightweight and compact, IP67 compliant for dust and water resistance and can withstand chemical disinfection. The devices' design makes them easy to assemble and repair, and access to the battery compartment is possible without special tools.

These adaptable enclosures allow for easy integration of different sensor shapes and battery types, allowing our client to upgrade or modify the products as new components become available. This flexibility will also protect the client from supply chain disruptions and extend the life of their products.

More of What We Do for Enclosure Design

- Mechanical Design of Enclosures: our full range of mechanical system design services, including hardware enclosures and electronics enclosures.

- Smart Wireless Thermostats: a case study of turnkey design, including unified hardware and software development.

- Sealing Enclosures for Electronic Devices: our review of different ways of sealing electronic devices, backed by successful case studies of completed projects.