AI + IoT in Industrial Automation: Key Integration Challenges and Engineering Solutions

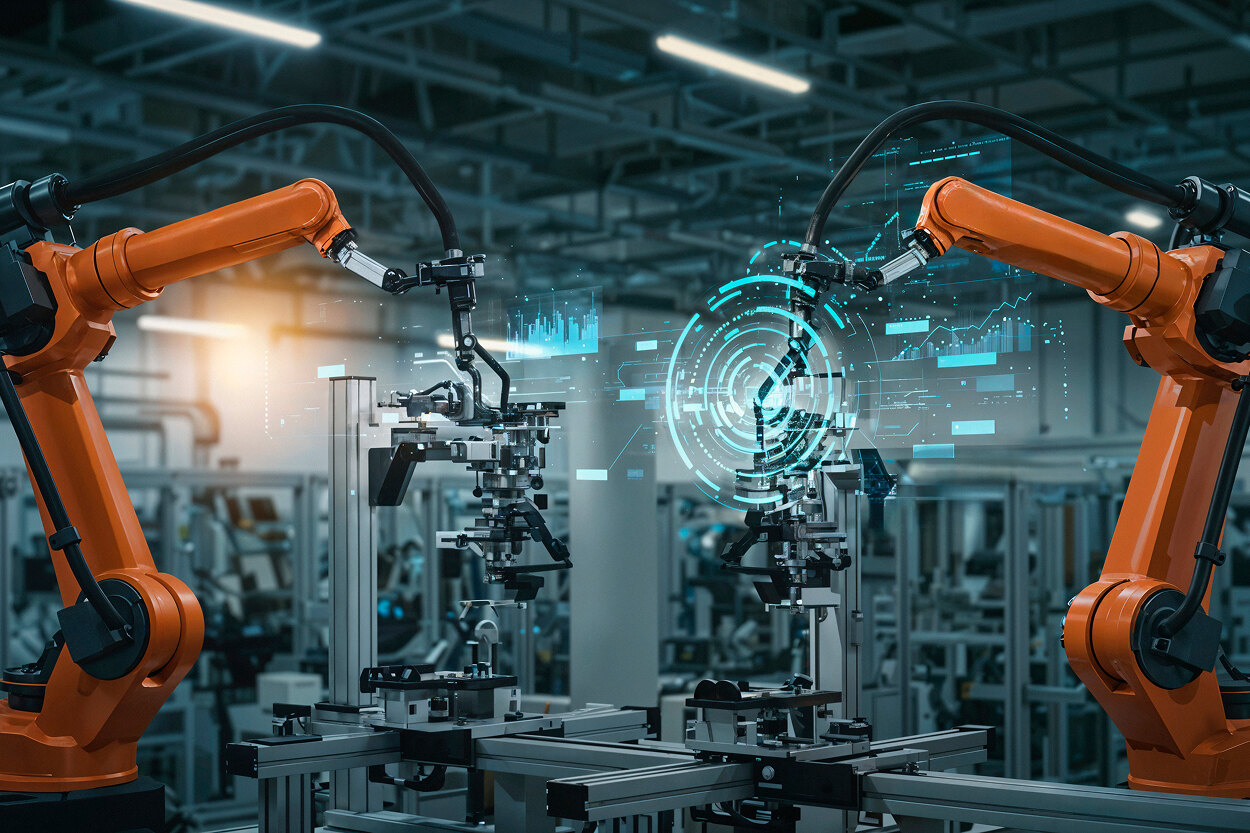

Industrial automation is undergoing a radical transformation thanks to the convergence of Artificial Intelligence (AI) and the Internet of Things (IoT). This integration — often referred to as the AIoT paradigm — brings unprecedented efficiency, predictive capabilities, and autonomy to manufacturing environments.

But merging these technologies is not a plug-and-play process. Engineers face numerous integration challenges related to connectivity, data processing, scalability, and system reliability. This article explores the technical aspects of integrating AI and IoT in real-world industrial automation systems — and how to overcome common roadblocks with solid engineering solutions.

What Is AIoT and Why It Matters in Industrial Automation?

AIoT refers to the fusion of artificial intelligence with IoT networks. In industrial settings, it typically includes:

- Edge or cloud-based AI models that analyze real-time data from industrial assets

- Sensors, actuators, and controllers connected via industrial protocols (e.g., OPC UA, Modbus, CANopen)

- Autonomous decision-making for process optimization, quality control, and predictive maintenance

The result? Smart factories that can reduce downtime, improve productivity, detect anomalies in real time, and support mass customization.

Key Technical Challenges in AIoT Integration

1. Data Interoperability Across Devices and Protocols

Industrial environments use a wide range of communication standards and legacy equipment. Connecting these diverse systems and enabling them to communicate effectively is a major hurdle.

Solution: Engineers must implement protocol converters, OPC UA wrappers, and unified data models (like Asset Administration Shells in Industry 4.0) to harmonize data across heterogeneous devices.

2. Real-Time Processing and Latency Constraints

AI algorithms require computational power and time — both limited in edge devices. Meanwhile, manufacturing systems demand sub-second reaction times.

Solution: Use of lightweight AI models, pruning, quantization, and deployment via inference accelerators (e.g., Nvidia Jetson, Coral TPU, or FPGA-based AI) can meet real-time constraints.

3. Edge vs. Cloud AI Deployment

Choosing between edge and cloud deployment impacts latency, data privacy, and cost.

Solution: A hybrid approach is often optimal. Time-sensitive tasks run on edge nodes; complex analytics and model training occur in the cloud. Engineers must design architectures that support seamless data flow and model synchronization.

4. Power and Thermal Constraints in Industrial Hardware

AI workloads demand significant power. In environments like motor controllers or sensor nodes, thermal limitations can degrade performance.

Solution: Custom embedded hardware with power-efficient chips (e.g., NXP i.MX, STM32, or RISC-V SoCs), plus dynamic workload management, can mitigate these constraints.

5. Ensuring Cybersecurity of AIoT Systems

Each added sensor or controller increases the attack surface. AI models themselves can be targets for adversarial attacks.

Solution: Employ secure boot, hardware-based encryption, OTA update security, and anomaly detection powered by AI to enhance cybersecurity.

Long-Tail User Questions and Answers

What are the best practices for integrating AI with legacy PLC systems?

To connect AI algorithms with traditional PLCs, use OPC UA gateways, modbus-to-MQTT bridges, or digital twins that mirror PLC behavior. Data can be extracted, normalized, and used to train edge AI models without interfering with existing logic.

How can manufacturers ensure real-time AI decisions on low-power embedded hardware?

Use TinyML techniques, including model compression and inference optimization. Pair this with specialized hardware (e.g., low-power AI chips) and real-time operating systems (RTOS) to reduce response latency.

Which industries benefit most from AIoT-based automation?

Sectors like automotive, food and beverage, semiconductor, pharmaceuticals, and heavy machinery benefit from AIoT, thanks to improved process control, quality assurance, and predictive maintenance.

Can AI help reduce machine downtime in predictive maintenance?

Yes. AI models trained on historical sensor data can detect early signs of failure, allowing planned maintenance before breakdowns occur. This improves asset availability and reduces maintenance costs.

Engineering Strategies for Successful AIoT Deployment

Develop a Modular and Scalable Architecture

Separate sensing, computing, and communication layers. Use microservices to deploy AI capabilities that can be independently updated and scaled.

Prioritize Data Quality from the Start

Use calibrated sensors, proper sampling rates, and timestamp synchronization to feed reliable data into AI systems.

Validate AI Models in Real-World Scenarios

Simulation is not enough. Use hardware-in-the-loop (HIL) setups and shadow modes to test AI behavior in live systems before full deployment.

Enable Continuous Model Updates

AI models degrade over time (data drift). Implement MLOps pipelines to retrain and redeploy updated models automatically.

Embrace Standards and Open Architectures

Adopt standards like MQTT, OPC UA, IEEE 1451, and open-source stacks to avoid vendor lock-in and simplify integration.

Final Thoughts

AI + IoT holds the key to the next generation of industrial automation. However, delivering production-grade AIoT systems requires a deep understanding of hardware constraints, embedded software, system integration, and security.

At Promwad, we support clients across industries with embedded engineering expertise, from edge hardware and firmware to AI optimization and connectivity. Our team ensures that your AIoT-enabled products perform reliably in the field — and scale with your needs.

Let’s explore how we can accelerate your AIoT development.

Our Case Studies