How Embedded Systems Enable Compliance: From Cybersecurity Standards to Green Regulations

Getting Started: Why Compliance Begins in the Embedded Stack

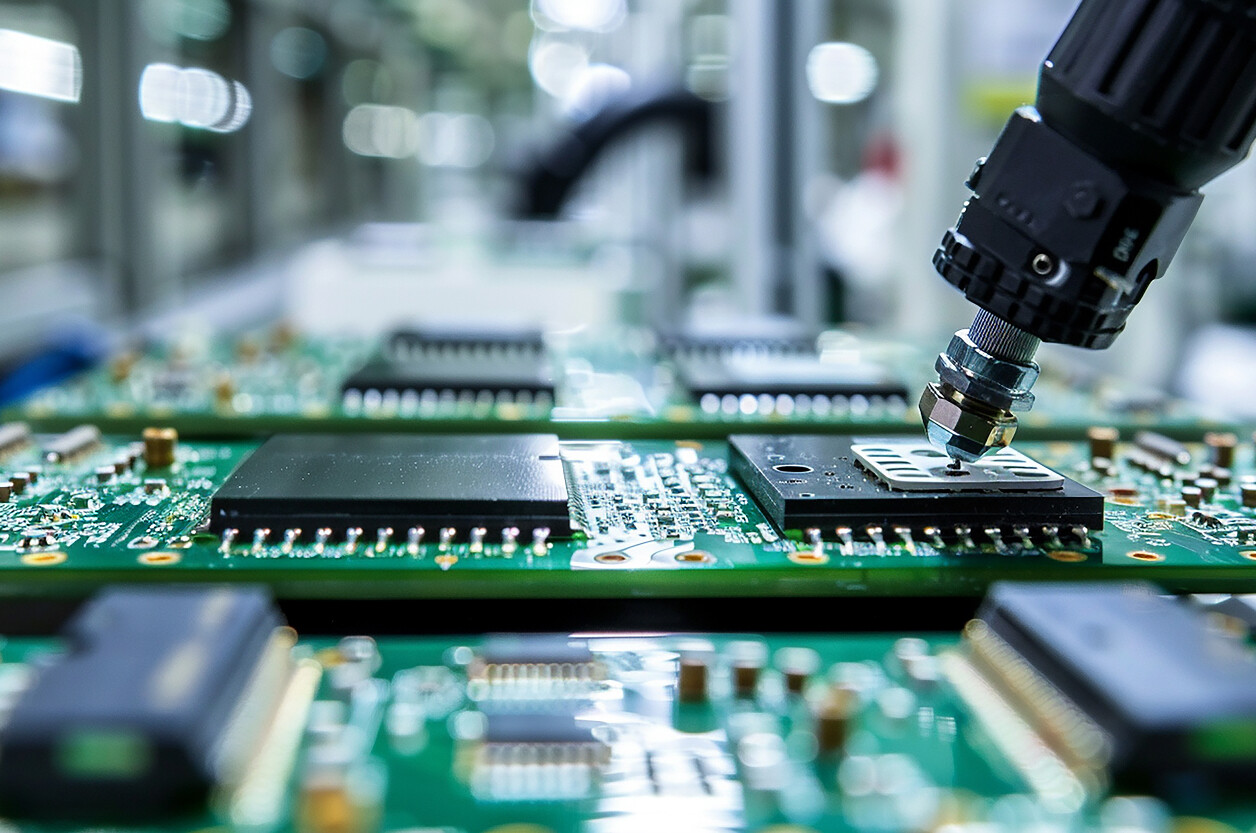

As regulatory demands increase across industries — from industrial automation and automotive to consumer electronics and medtech — embedded systems are emerging as the first line of defense for compliance.

From cybersecurity baselines to environmental data traceability, your device's microcontroller, firmware, and interfaces now play a critical role in satisfying audits, certifications, and legal requirements.

In this article, we explore how embedded systems support modern compliance initiatives, including:

- Cybersecurity frameworks like IEC 62443, ISO 21434, and ETSI EN 303 645

- Safety standards like ISO 26262 and IEC 60601

- Green regulations like CSRD and Digital Product Passports (DPP)

1. Cybersecurity Compliance Begins at the Firmware Level

Key standards addressed:

IEC 62443 (Industrial cybersecurity)

ISO/SAE 21434 (Automotive)

ETSI EN 303 645 (Consumer IoT)

Embedded system responsibilities:

- Secure boot and firmware integrity

- Runtime isolation between functions

- Secure storage and update mechanisms (OTA)

- Logging and traceability of security-relevant events

Promwad Insight: We implement secure bootloaders and encrypted OTA pipelines on platforms like STM32, NXP i.MX, and Nordic nRF to help OEMs achieve PSA Certified and SESIP alignment.

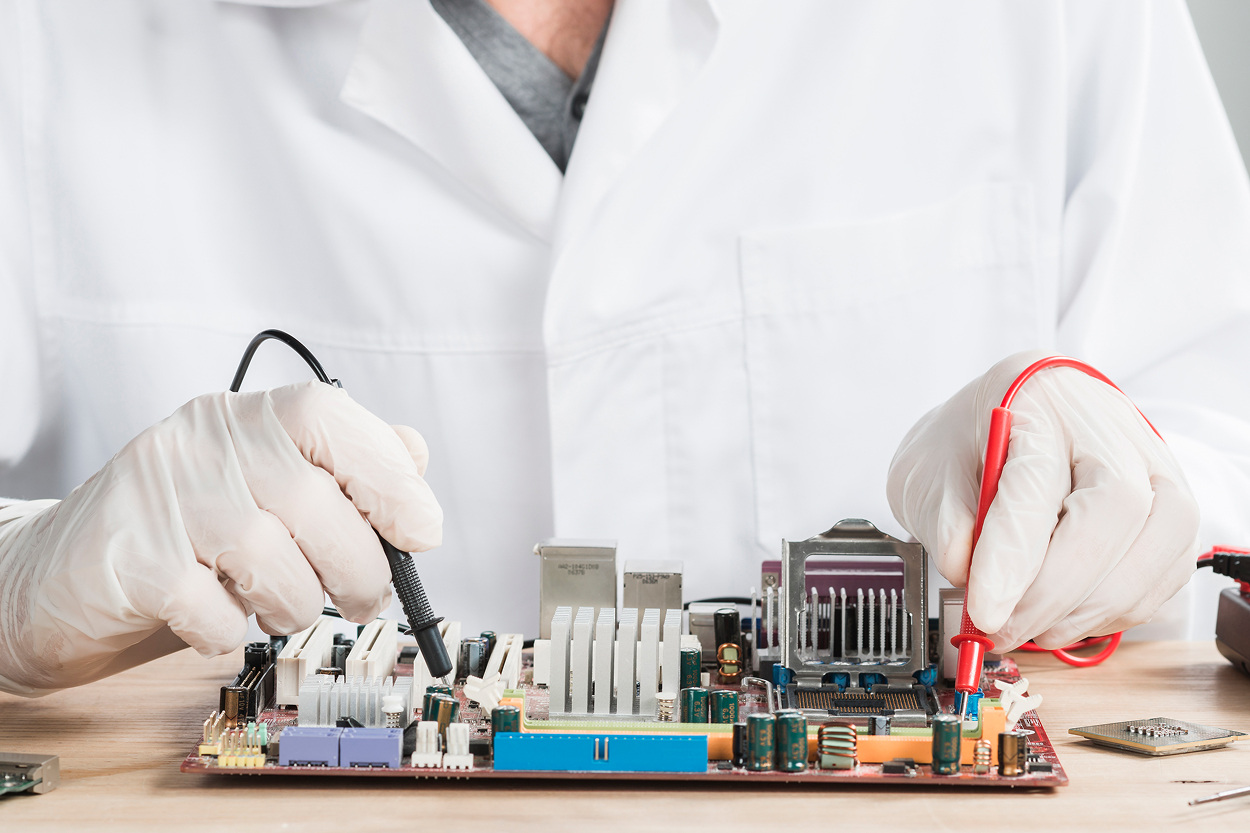

2. Functional Safety Support with Embedded Architecture

Key safety standards:

ISO 26262 (Road vehicles)

IEC 61508 (General industrial safety)

IEC 60601 (Medical electrical equipment)

Embedded system contributions:

- Watchdog timers, redundancy checks, and self-diagnostics

- Memory protection units (MPU/MMU)

- ASIL decomposition support and safe-state fallback logic

Use case: An automotive supplier achieved ASIL B readiness by combining QNX RTOS with redundant ADC signal validation in its ECU firmware.

3. Traceability for Green Regulations and DPP Readiness

Regulatory context:

Digital Product Passport (EU)

Corporate Sustainability Reporting Directive (CSRD)

Embedded system requirements:

- Lifecycle and usage data capture (cycles, temperature, energy use)

- Serial-level traceability for part origin and recyclability

- Secure storage of compliance metadata (via TPM or MCU flash)

Example: A consumer electronics company logs battery cycle count and energy efficiency telemetry locally, which is exported as part of its DPP file structure during factory testing.

4. OTA Infrastructure as a Regulatory Enabler

With connected devices, regulations increasingly require:

- Ongoing patching capabilities

- Transparent user consent for updates

- Logging of software version history

Embedded OTA stack elements:

- Version-controlled bootloaders

- Differential updates with encryption

- Update verification via cryptographic signatures

Result: Reduced recall risk, improved auditability, and alignment with GDPR and NIS2 directives.

Summary Table: Compliance Domains and Embedded System Roles

| Regulation/Standard | Industry Focus | Embedded Responsibilities |

| IEC 62443 / ISO 21434 | Industrial, Auto | Secure boot, access control, firmware signing |

| ISO 26262 / IEC 60601 | Automotive, Medical | Self-checks, safe states, signal integrity |

| ETSI EN 303 645 | Consumer IoT | Password enforcement, remote update restrictions |

| Digital Product Passport | All (EU) | Usage logs, recyclability metadata, part traceability |

| CSRD / ESG Reporting | Enterprise-wide | Energy consumption monitoring, carbon data capture |

Real-World Case Study: Embedded Compliance in an EV Charging Station

A European cleantech company partnered with Promwad to launch a network of smart EV charging stations across the DACH region. The hardware needed to comply with:

- IEC 62443 (industrial cybersecurity)

- ISO 15118 (V2G communication)

- EU Digital Product Passport requirements (environmental footprint and recyclability)

Embedded strategy implemented:

- Developed a secure OTA system with FOTA and SOTA support based on encrypted MQTT

- Implemented a dual-partition firmware system with rollback and audit logging

- Embedded a secure element for storing charging history, part provenance, and carbon data

- Created a DPP export mechanism for factory end-of-line upload

Results:

- First-pass certification with TÜV and ISO auditors

- Full traceability of energy usage, firmware version, and device lifecycle

- Alignment with upcoming EU EV infrastructure regulations for recyclability and software transparency

Final Thoughts: Compliance Starts Where Your Code Does

Today’s regulatory landscape puts embedded systems at the center of compliance — not just as technical enablers, but as auditable, visible parts of the product.

With the right firmware architecture, hardware platform, and security protocols, OEMs can meet regulatory demands with confidence — and create a stronger, longer-lasting relationship with customers and partners.

At Promwad, we help clients embed compliance from day one — whether through OTA design, traceability frameworks, secure boot strategies, or DPP readiness planning. Let’s build not just smart devices — but responsible ones.

Our Case Studies in Electronics Manufacturing