Client

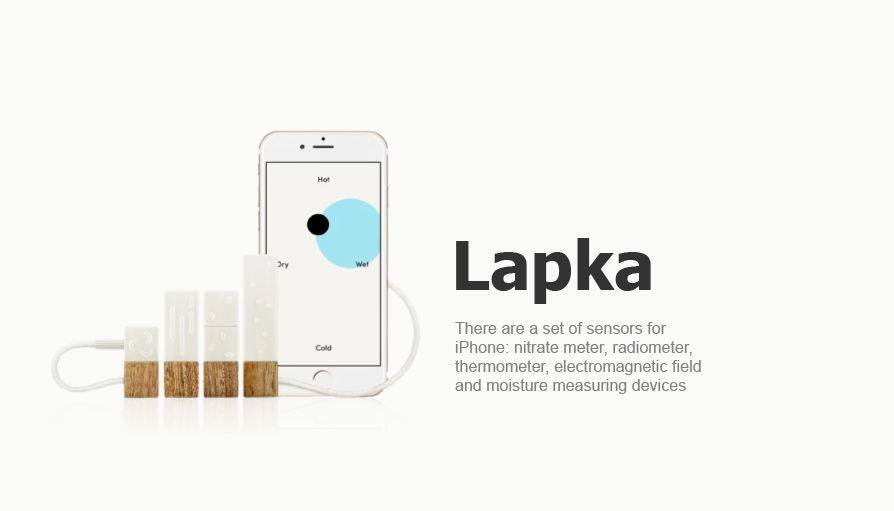

Lapka is the design and concept developer of the Lapka device (2012), a miniature sensor that connects to a phone and measures, collects, and analyzes the content of the environment.

Pictures used here are taken from join-real.com

Objective

Develop and manufacture initial batch of Lapka devices based on the design and primary technical requirements of the client.

Lapka product is a set of four sensors that connect to a phone through audio interface:

- Radiometer

- Electromagnetic field sensor

- Fruit and vegetable nitrate sensor

- Humidity sensor

Each sensor represents a wooden block with an audio cable outlet. Its design and proportions are built onto a cube with 19mm edge.

The following tasks were highlighted based on the client’s primary requirements:

Task 1. Choose materials for the body of the device using the following parameters:

Plastic

The main requirement for the plastic is deep white matte color. Other criteria include density of the material, hardness, and tactile qualities.

Wood

The main requirements include hard wood, preferably polished only, without coating, in dark color.

The final choice for the specific type of plastic and wood had to be performed at the stage of prototype manufacturing, based on the samples provided.

Metal

This material is used for the production of the nitrate sensor probe. The main criteria for the metal choice include resistance to the aggressive media (vegetable and fruit juices) that will be in contact with the probe; attachment of the removable part of the device to the body without external fasteners is required.

Task 2. Parts design.

During the design process, it is necessary to study the following questions:

- Coordinate production of the metallic and plastic parts with the technologists

- Select optimal attachment of the board in the body

- Draw the schemes for the nitrate sensor’s metallic part (base with the probe) based on the manufacturing technology and coordinate them with the production and developers

- Choose the best option for the location of the plastic socket in the wooden part (reliable attachment, designed for manufacturing)

- Revise the labeling technology with the producer of mechanical parts

- Study the audio jack, its installation onto the board and assembly into the body. The main requirement for the jack besides security is its appearance in the assembled product, i.e. it should not have the standard black ring from the connector

Task 3. Produce the prototypes.

They have to be made using diverse materials and closely match the serial product

Task 4. Manufacture equipment for mass production.

For serial production, it is necessary to manufacture a set of molds for casting plastic details, equipment for production of the metal probe for the nitrate sensor, as well as the equipment for wooden parts production.

Task 5. Produce an initial batch of the body sets for all sensor devices

Solution

1. Materials selection

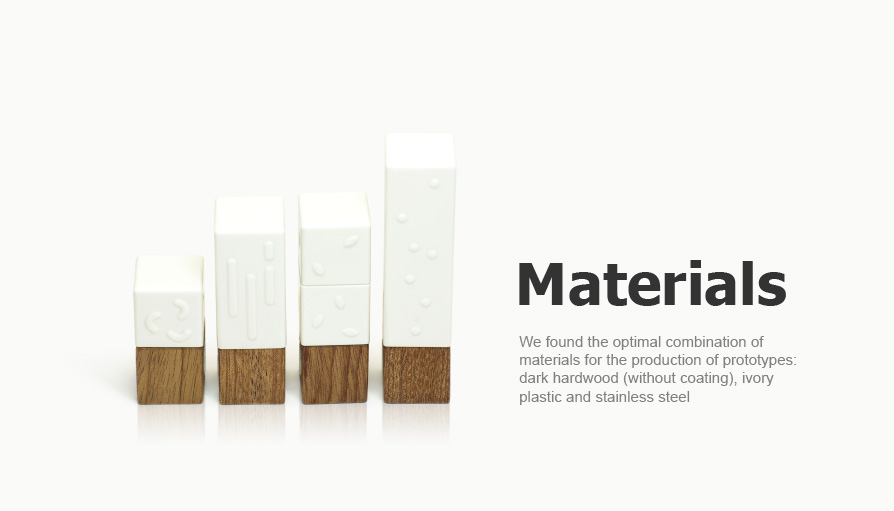

Based on the client's requirements and production technology, three options of plastics were proposed that had required density, strength, rates of absorption/refraction, and tactile qualities. These materials were chosen for the subsequent production of prototypes.

To choose material for the wooden parts of the device, samples of required size from nine different types of wood were produced and presented to the client. Monitoring and selection of wood-processing factories was conducted. At the stage of the samples evaluation, three types of wood were chosen and subsequently used in the prototype production.

Stainless steel was chosen for the production of the probe. While studying the design of the nitrate sensor, it was decided to use two different grades of steel, for the base of the probe and for its working part, since it is necessary to detach the sensor for measuring and then reliably attach it without additional fasteners.

To provide necessary function, different grades of stainless steel were used. They include grades with pronounced magnetic qualities for the base and permanent ring magnet with 4 kg pull force built into the case of the device for secure attachment of the base, as well as a non-magnetic grade of stainless steel for the probe. This choice allowed preventing interaction between the probe and the magnet when the device is in the “transport” mode.

2. Design development

At this stage, 3D models and design documentation for all parts of the product were developed. In addition, secure attachment of the printed circuit boards inside the plastic case, as well as molded slopes based on the design requirements were planned.

Close attention was paid to the tightness of the probe attachment to the nitrate sensor to avoid diffusion of aggressive liquids into the device. Highly fluid plastic with strong metal adhesion was used to provide probe hermeticity. The color of the insulating plastic matches the exact color of the case. In order to avoid faulty attachment of the nitrate sensor’s probe to the standard audio jack, the size of the probe was made nonstandard.

In the process of the project implementation, it was decided to produce individual audio jack built inside the case. The necessity for the separate port was dictated by the demanding appearance of the device, i.e. absence of any interconnected surfaces and visible gaps on the body of the device. At the same time, technology of the device assembly was simplified.

3. Design development

At this stage, three sets of prototypes were produced using pre-selected materials.

Analysis of the prototypes introduced modifications in the design of the plastic cases, such as removal of external molded slopes and corrections in labeling.

4. Equipment production

At this stage, equipment sets were made for the subsequent serial production of the parts sets. Reference samples of the parts were made and confirmed with the client using this equipment.

5. Initial batch production

Initial batch of the sensors’ parts sets was produced. Acceptance criteria of all the product components were formulated and quality control was conducted. Results of the initial batch production allowed to adjust the technology process for optimization of product assembly and operation, as well as increased yield of quality devices.

As a result of this work, full design documentation package optimized for serial production and equipment set for subsequent manufacturing were produced, while one batch of products was sent for trial.

Advantages

- Use of contemporary design, organic materials (wood), as well as high-quality ivory-like matte plastic allowed creating aesthetically attractive device that stands out in comparison to other sensors

- All materials were checked on prototypes, where client could assess such parameters as color, weight, and tactile qualities in practice

- Generated design documentation for the set of sensors was optimized for mass production