Power Electronics: Europe's Path to Energy Independence Through Innovation

There is no doubt that investing in research and development is the only way to build competitive power electronics components in the future.

Europe's reliance on rare earth metals threatens its energy security and technological sovereignty. As global supply chains weaken, the solution isn't just securing materials — it's reinventing how we use them through advanced power electronics.

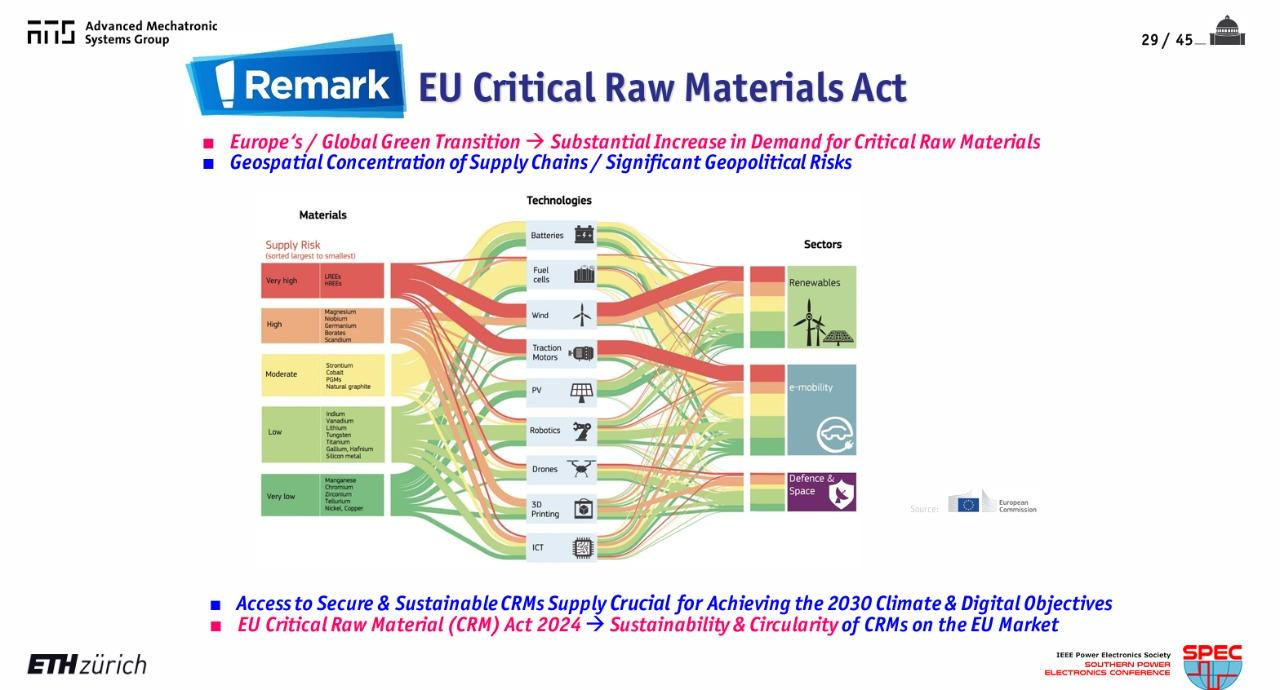

Overview of the EU Critical Raw Materials Act

Source: European Commission, presented by the Advanced Mechatronic Systems Group, ETH Zürich at the IEEE Southern Power Electronics Conference (SPEC).

Europe's renewable energy, electric mobility, and defense industries are highly dependent on critical raw materials, many of which face supply chain risks. The EU's CRM Act aims to secure, diversify, and ensure the circular use of these materials to meet climate and technological objectives.

The EU Critical Raw Materials (CRM) Act 2024 is a legislative initiative aimed at ensuring the European Union’s secure, sustainable, and resilient supply of critical raw materials essential for the green and digital transitions.

The Act sets targets for domestic extraction, processing, and recycling of key materials like lithium, rare earths, and cobalt, while also promoting strategic partnerships with third countries. It emphasises reducing dependency on a few suppliers, strengthening circularity, and streamlining permitting for CRM projects within the EU to support clean energy, mobility, and digital industries.

Power Energy Challenges and Solutions

The shift to sustainable energy and electric mobility is accelerating, but behind the scenes, there's a silent struggle. Technologies like DC-DC converters, AC-AC converters, battery management systems (BMS), and battery charging stations (BCS) rely heavily on rare earth metals.

From converters and inverters that manage energy flow to BMS – rare earths are embedded in every layer. The problem? Most of these materials come from a handful of countries, creating a fragile supply chain that could break under global pressure.

At the same time, different areas of green energy have their own special challenges and solutions.

Wind power challenges

1. Grid instability caused by wind power variability

The variable nature of wind energy generation introduces frequency and voltage fluctuations that can compromise grid stability. To mitigate these effects, modern wind turbines employ advanced power electronics, including:

- Grid-forming inverters with synthetic inertia capabilities.

- Adaptive converters using SiC/GaN semiconductors for faster response.

- Predictive control algorithms (e.g., model predictive control) for real-time adjustment.

These solutions enable seamless low-voltage ride-through (LVRT) compliance, dynamic reactive power support (IEEE 1547-2018), and 98%+ power conversion efficiency even during ramping.

2. Energy storage limitations

While energy storage systems (ESS) are critical for mitigating wind power intermittency, their effectiveness is constrained by capacity limitations (typical 4–8h duration for grid-scale batteries) and round-trip efficiency (70–90% for Li-ion, 40–70% for hydrogen storage).

Advanced power electronics address these challenges through:

- Adaptive battery management systems (BMS) with model-predictive control.

- Grid-tied hybrid inverters (SiC-based, >98% efficiency) for seamless PHS/CAES integration.

- Dynamic power allocation algorithms that optimise state-of-charge (SOC) balancing, degradation-aware dispatch and ancillary service coordination.

3. Integration with existing power grids requiring advanced control systems

The interconnection of wind power plants with traditional power networks introduces complex stability and control challenges due to variable power injection patterns, reduced system inertia and dynamic voltage/reactive power interactions.

Modern solutions leverage advanced power electronic systems:

- Wide-bandgap converters (3.3kV SiC MOSFET-based STATCOMs and GaN HEMT inverters).

- Grid-support technologies (adaptive PLL architectures, DSP-controlled voltage regulators, real-time PMU-based monitoring).

- System-level controls (model-predictive current controllers and inertia emulation through synthetic governor response).

These solutions provide sub-cycle fault response (<16ms), 0.95–1.05 pu voltage maintenance and IEEE 1547-2018 compliant fault ride-through.

| Technology | MOSFET | IGBT | SiC (Silicon Carbide) | GaN (Gallium Nitride) |

| Structure | Metal-Oxide-Semiconductor Field-Effect Transistor | Insulated Gate Bipolar Transistor | Wide-bandgap MOSFET | Wide-bandgap HEMT (High Electron Mobility Transistor) |

| Best For | High-frequency switching (kHz range) | High-voltage/power applications (600V-6.6kV) | High-voltage, high-temperature (600V-10kV) | Ultra-high frequency (MHz range) |

| Switching Speed | Fast (ns) | Moderate (μs) | Very Fast (ns) | Extremely Fast (sub-ns) |

| Voltage Range | <250V | 600V-6.6kV | 600V-10kV+ | <650V |

| Efficiency | Good at low voltages | Good at high power | Excellent at high voltages | Best at high frequencies |

| Thermal Performance | Moderate | Good | Excellent (operates to 200°C+) | Good (but sensitive to heat) |

| Cost | Lowest | Moderate | High | Highest |

| Key Applications | SMPS, DC-DC converters | Motor drives, inverters | EV chargers, solar inverters | RF, fast chargers, 5G |

Power transistor technologies comparison

Promwad’s Role: Turning Challenges into Opportunities

We cannot solve the world’s resource problems. We’re here to build the technology that makes those problems irrelevant. Our expertise lies in developing high-efficiency converters and inverters, power electronics, solar, wind, drones, and industrial automation.

At Promwad, we offer end-to-end power electronics design services for low-, medium-, and high-voltage applications, using the latest in MOSFET, IGBT, SiC, and GaN transistor technologies. We support projects from initial concept through to production for industrial automation, power engineering or building automation.

Our expertise covers the development of motor controls, converters, inverters, power supply units, energy storage systems, and battery management systems, along with wireless power transfer, HVDC transmission, and smart power distribution systems.

To ensure optimal performance, we integrate capabilities such as DSP and firmware development, FPGA design, PCB simulation, thermal and mechanical analysis, and comprehensive EMC testing. Here is how we can help:

DSP and firmware development

With deep expertise in digital signal processing applications, our engineering team develops optimised firmware for power conversion systems. We adjust control parameters - from switching timing to modulation schemes - to deliver superior performance and reliability for your power electronics designs.

FPGA design

Our expertise lies in developing advanced control systems for power electronics, implementing precision PWM generation, closed-loop control algorithms, and accurate voltage/current regulation. We integrate hardware-based fault detection circuits with sub-microsecond response times, providing robust protection against overcurrent, overvoltage, and thermal runaway conditions.

PCB design simulation

We employ industry-standard EDA tools including Altium Designer and Siemens PADS Professional for PCB design and simulation. Our layouts incorporate controlled impedance traces, optimised thermal via arrays, and strategic power domain partitioning to achieve optimal power integrity and thermal performance.

Thermal simulation

We perform comprehensive thermal analysis using advanced power electronics simulation tools, evaluating heat transfer mechanisms including conductive, convective, and radiative pathways.

Our thermal optimisation process encompasses heatsink geometry refinement, strategic component positioning, and airflow management to guarantee stable performance across diverse operating conditions and ambient temperature ranges.

Topologies we support

Basic Converters

| Advanced Systems

|

Intermediate Converters

| Special Techniques

|

Schematic design simulation

We leverage industry-standard simulation platforms including SPICE and PLECS to rigorously analyse power electronic circuits. Our simulation capabilities enable comprehensive validation of critical operational parameters - from voltage/current characteristics and dynamic responses to component stress analysis - ensuring optimised performance and reliability.

Thermal, mechanical, and EMC testing

We conduct rigorous product validation through thermal cycling, vibration analysis, and EMC testing using IEC 61800-3 and EN 61000-compliant equipment. Our testing procedures verify both regulatory compliance and operational reliability under extreme environmental conditions.

Explore the most popular power electronics solutions from Promwad

Energy Storage Systems (ESS)

Energy storage systems play a crucial role in balancing renewable energy generation and grid demand. They include lithium-ion batteries, flow batteries, pumped hydro storage (PHS), and supercapacitors, providing backup power, frequency regulation, and peak shaving. Advanced ESS integrates with smart grids and hybrid renewable systems for optimal energy management.

Converters

Converters transform electrical energy between different voltage levels and forms (DC-DC). They are essential in renewable energy systems, electric vehicles (EVs), and industrial applications. Modern converters use SiC/GaN semiconductors for higher efficiency, compact designs, and better thermal performance.

Inverters

Inverters convert DC power (from solar panels, batteries, or fuel cells) into grid-compatible AC power. Grid-tied inverters ensure synchronisation with utility networks, while off-grid inverters support standalone systems. Advanced models feature MPPT tracking, reactive power control, and black-start capability.

Rectifiers

Rectifiers convert AC to DC, widely used in power supplies, EV chargers, and industrial equipment. High-efficiency active PFC (Power Factor Correction) rectifiers minimise harmonic distortion and improve grid stability.

Case Studies

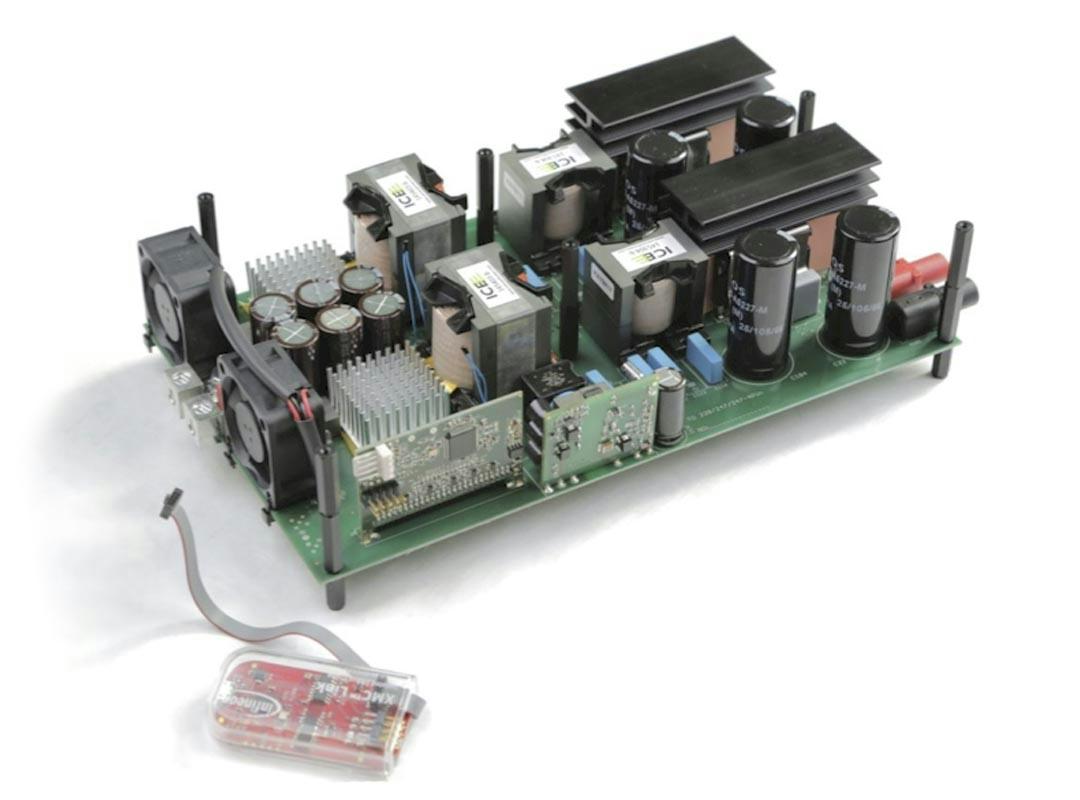

4kW dual-phase LLC

We've engineered a high-performance power board (dual-phase LLC) for our Canadian client, integrating high-voltage and low-voltage power MOSFETs.

Key features:

- Dynamic control

- Efficiency controller

- The TMS320 family of digital signal processors

- Peak efficiency >98.3%

- Flat efficiency plot from 10% to 100% load

- Output voltage min/max 44 V/58 V

- Complete digital control for dual-phase LLC: phase shedding, current sharing, etc.

- Diagnosis and prevention of LLC capacitive mode and MOSFET body diode hard commutation

- User interface for parameters setting and monitoring

- PI/PID controller

- Balancer function

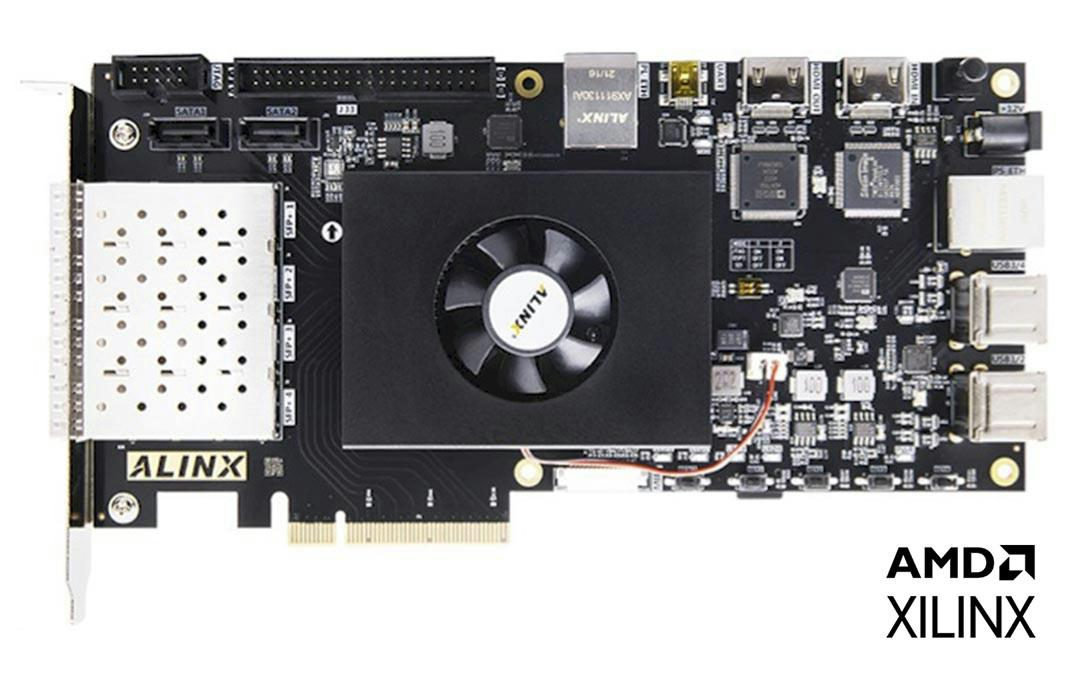

MMC converter

As a power electronics company, we participated in the development of algorithms for modular multi-level converter (MMC) for high-voltage direct current (HVDC) transmission.

Key features:

- Full-bridge submodules

- DSP/FPGA

- Real-time synchronisation protocol with SFP

- DC fault detection (valve overcurrent, DC pole undervoltage / voltage differential / overcurrent, and DC current differential)

- Synchronisation via IEEE1588 with limited accuracy

- Synchronisation accuracy is ±2-4 ns, ultra-fast communication

Why Invest in Power Electronics? Because the Alternative Is Obsolescence

Today companies that fail to invest in technology become irrelevant. Here’s why smart businesses are doubling down on power electronics:

- Efficiency equals profit. Advanced converters and inverters slash energy waste, cutting costs while reducing environmental impact.

- Less reliance, more resilience. Boosting efficiency means using fewer rare earth materials, protecting your supply chain from global disruptions.

- Own your tech, own your future. Investments in R&D keep critical technologies in-house and safeguardes your business from external risks.

Europe’s Path Forward: Compete with Innovation, Not Resources

If Europe wants to stay competitive, it must invest in its own technological ecosystem. This means building world-class BMS, refining power converters, and creating next-gen inverter technologies. Without this focus, Europe risks trading one dependency (rare earths) for another: foreign tech solutions and outsourced R&D.

But it doesn’t have to be that way.

While other regions control raw materials, Europe can dominate through engineering excellence. By investing in power electronics, we can secure a future defined by innovation, sustainability, and self-reliance.

Switzerland is a leader in power electronics not because of resource wealth – they lead because they invest heavily in R&D. Swiss technical universities like ETH Zurich and EPFL Lausanne play a crucial role in semiconductor research and producing talented graduates for the industry. As a hotbed of innovation, they are consistently pushing the boundaries of what’s possible with advanced power electronics.

Promwad’s state-of-the-art power electronics solutions are designed to meet today’s toughest challenges and tomorrow’s biggest opportunities.

Let’s build that future together!