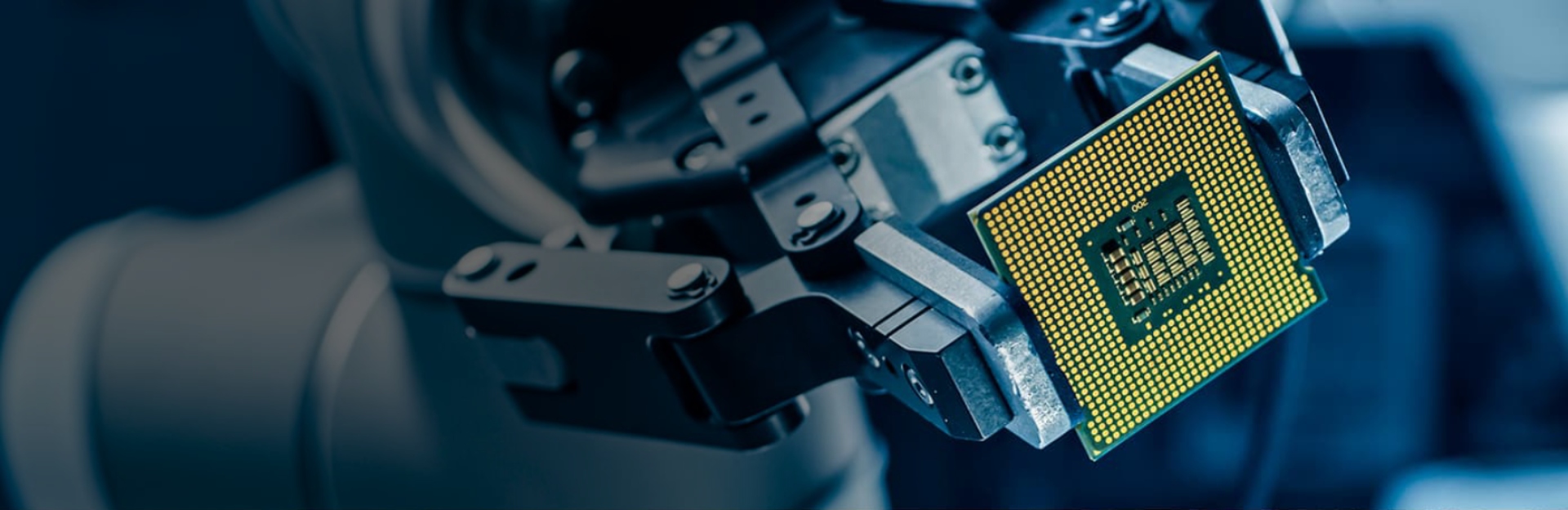

Electronics

Manufacturing

EMS: Electronics Manufacturing Services

Custom electronic manufacturing services at Promwad is your opportunity to launch electronic production at proven facilities in Europe, China, and Southeast Asia – we choose the best options in terms of budget and technology, timing control, and quality.

Our experts implement all turnkey contract manufacturing stages: development of printed circuit boards and samples, production of enclosures, installation and assembly of devices, testing, and certification preparation.

Turnkey Manufacturing in China and SEA

Problem

Suppose a company hasn't conducted a foreign economic activity with China or does it rarely. In that case, it will spend extra thousands of dollars and additional time each month to build electronic manufacturing processes from scratch.

Benefits

2,000-3,000$ monthly savings because the company doesn't have to employ a specialist in foreign economic activity with experience in the market, logistics, and specialists in cross-communication and process organisation.

Our solution

Delivery

Delivery

We organise the delivery of your batch from China and SEA, relying on our knowledge of law and logistics experience in these regions

Contacts

Contacts

We commit ourselves to communication and take responsibility for deadlines and quality

Savings

Savings

We provide full service and guarantee the result at an affordable price

Analysis

Analysis

Constant market analysis and audit of our current and new suppliers

Our Product Launch Expertise

Problem

If a company tries to launch its production, it will take a lot of time to establish and control processes, while a lack of competencies will cause defects in 7-8 % of cases. When trying to parallelise tasks by hiring several suppliers, project deadlines and budgets will increase.

Benefits

We know how to organise work to decrease time-to-market to at least 10-12%, labour costs — to 17%, and reject rate — to 1-2%.

Our solution

Pro level

Pro level

Adapted communication between experienced developers and production support managers

One-stop

One-stop

Projects in mechanical and industrial design with subsequent production

In time

In time

We are not interested in a deadline extension due to direct losses and customer dissatisfaction

Result-focused

Result-focused

We correct mistakes at every stage without delay

Our Competencies

We are ready to take responsibility for the entire turnkey process, through our electronic design and manufacturing services:

Trusted site

Selection of optimal sites for production launch

Planning

Setting of terms, creating supply chains

Enclosure

Production of fixtures and moulds for enclosures and delivery of enclosures in batches

Packaging

Development and production of brand packaging for electronic devices

Quality

Quality control and preparation for certification testing

All-inclusive

Mounting, assembly, packaging, and repairs at the production site

As a result of our electronic contract manufacturing services, you get a batch of commercial off-the-shelf products, starting from 1,000 pieces, produced at the agreed price and quality specifications.

Advantages of Our Services

Whether developing a new enclosure design or an electronic device, our team always conducts production capacity analysis for customers with their own capacity and those planning to outsource.

As an electronic manufacturing services (EMS) company, we have established contacts with contract manufacturers who have already passed our certification. Our qualified technical support of your projects on the development and production of serial products allows you to minimise risks and final costs.

"To launch mass production, it is necessary to adapt design documentation, launch the installation batch, and only then pass a phased increase in output. As a result, the customer receives the projected price of the finished product and the ability to control the process".

— Ivan Kuten, Co-owner & Tech Expert at Promwad

Our Case Studies in Electronic Manufacturing

Do you need a quote for your electronic manufacturing solution?

Please, drop us a line. We will contact you today or next business day. All submitted information will be kept confidential.