Custom vs Off-the-Shelf Hardware: How to Choose for Your Industry

Introduction: One Size Doesn’t Fit All

When designing a new embedded system — whether it's an IoT device, industrial controller, or smart sensor — one of the most strategic decisions is whether to build custom hardware or use off-the-shelf (OTS) components like commercial SoMs, dev boards, or standard modules.

The right answer depends on your industry, product goals, lifecycle, and budget. In this article, we’ll break down the pros and cons of each approach, and help you choose the right strategy based on your application.

1. Off-the-Shelf Hardware: Speed and Simplicity

OTS hardware includes:

- Evaluation boards and reference designs

- Commercial SoMs (e.g., Raspberry Pi CM4, Jetson Nano, ESP32 modules)

- Pre-certified communication modules (BLE, Wi-Fi, LoRa, LTE)

Advantages:

- Fast prototyping and reduced time-to-market

- Certified wireless stack and regulatory compliance (CE, FCC)

- Lower upfront engineering cost

Trade-offs:

- Limited customization (e.g., ports, interfaces, power budget)

- Higher per-unit cost at scale

- Supply chain dependency and lifecycle uncertainty

OTS is ideal for MVPs, short production runs, and early-stage market validation.

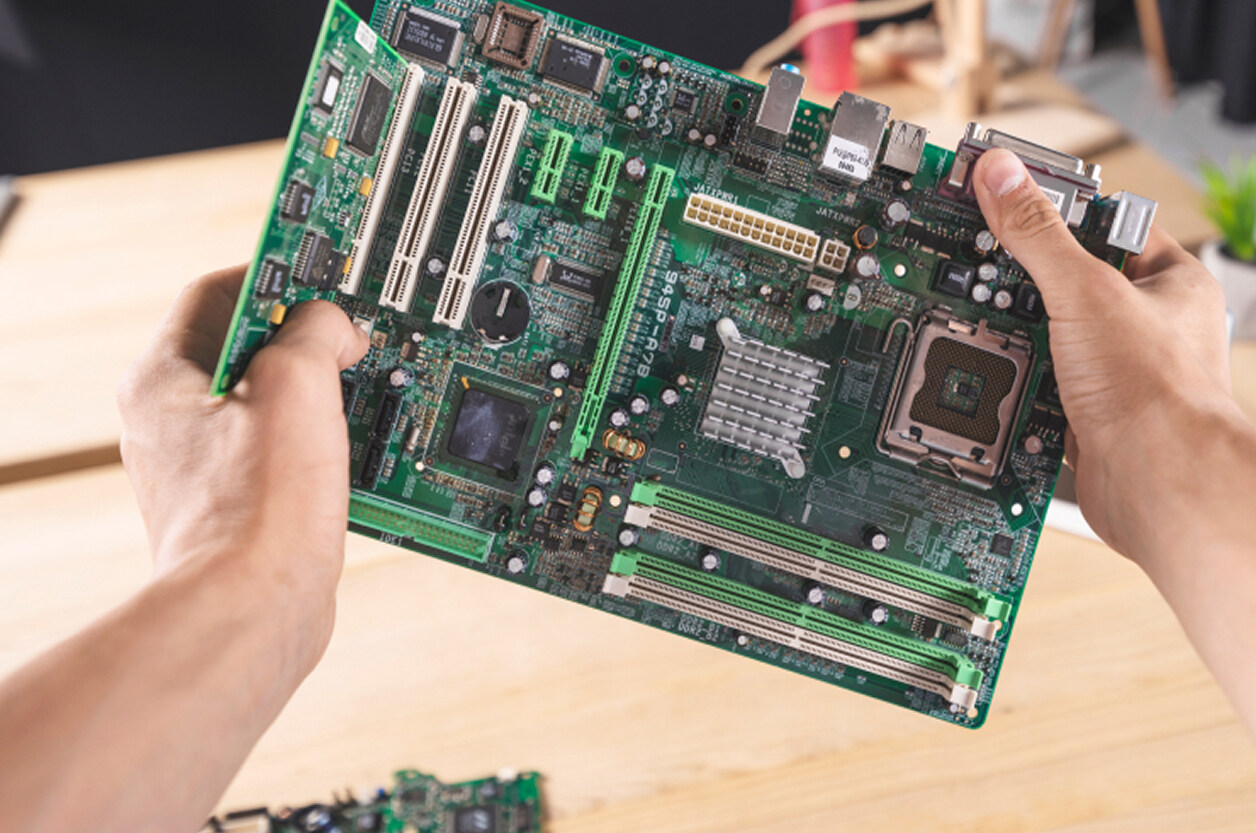

2. Custom Hardware: Control, Optimization, and Differentiation

Custom hardware involves designing your own:

- PCB with selected MCU/SoC and peripherals

- Mechanical enclosure and power system

- Interfaces, sensors, and connectors

Advantages:

- Fully optimized for size, cost, performance, and power

- Freedom to meet unique mechanical or thermal constraints

- Enables deep integration with firmware and test strategy

Challenges:

- Higher NRE (non-recurring engineering) cost

- Longer development and certification cycles

- Requires experienced hardware and DFM/EMC expertise

Custom hardware is the way to go for high-volume products, long-term platforms, or specialized use cases.

3. Industry-Specific Considerations

| Industry | OTS Hardware is Good For | Custom Hardware Recommended For |

| Consumer Electronics | Fast MVPs, smart home, wearable prototyping | Brand-specific wearables, custom UX or form factors |

| Industrial Automation | Gateway trials, protocol evaluation | Harsh environment, DIN-rail mounting, TSN support |

| Medical Devices | Feasibility studies, non-clinical tools | ISO 13485-ready systems, secure boot, traceability |

| Automotive | Concept demos, aftermarket solutions | Functional safety (ISO 26262), ASIL integration |

| Telecom & Networking | Software testing, lab evaluation | High-speed routing, optimized thermal and EMI design |

4. Hybrid Approach: The Best of Both Worlds

Many successful projects use a hybrid model:

- Start with an OTS module (e.g., SoM or SBC) for MVPs

- Switch to a custom carrier board + SoM when scaling

- Final phase: fully integrated custom PCB when mature

This model allows:

- Faster early validation

- Flexibility to pivot product features

- Cost optimization before full NPI (New Product Introduction)

Promwad often supports this migration path — combining fast time-to-market with scalable design evolution.

5. Cost & Timeline Comparison

| Parameter | Off-the-Shelf Solution | Custom Hardware Design |

| Time-to-market | 2–4 weeks | 3–6 months |

| NRE cost | Low | Medium to High |

| Per-unit cost (high vol.) | High | Lower |

| Certification effort | Minimal (pre-certified) | High (custom testing required) |

| Supply chain flexibility | Low | High |

6. Case Study: Migrating from Off-the-Shelf to Custom Design

A European medtech startup began with an off-the-shelf Wi-Fi-enabled sensor platform for air quality monitoring in hospitals. After successful pilot deployments in 10 clinics, they faced limitations:

Challenges:

- Module availability issues and long lead times

- Excessive power consumption for battery-based operation

- Limited options to integrate with hospital IT infrastructure

Promwad’s solution:

- Designed a custom PCB using an energy-efficient MCU and dedicated analog front-end

- Integrated a secure BLE + Wi-Fi combo chip for healthcare IT compliance

- Optimized power management for 6-month battery life

Results:

- 45% reduction in per-unit cost at 5,000-unit scale

- 2x longer runtime compared to off-the-shelf version

- Smooth CE and MDR pre-certification path due to tailored design

Final Thoughts: Match Strategy to Your Product Lifecycle

Your choice isn’t just technical — it’s strategic. Startups may begin with off-the-shelf to validate ideas, while mature companies move to custom to optimize for performance, cost, and brand.

Promwad supports tech companies across both paths — from early prototyping with commercial SoMs to turnkey custom design for mass production.

Let’s define the right hardware strategy for your industry and product roadmap.

Our Case Studies in Hardware Design