The Future of Open Hardware Platforms in Regulated Industries

Introduction: Open Hardware Meets Compliance

Open hardware platforms like Raspberry Pi, BeagleBone, and RISC-V development boards have fueled rapid innovation in consumer, education, and industrial prototyping. But can these platforms find a permanent home in regulated industries such as automotive, medical devices, or energy?

This article explores the evolving role of open hardware in regulated domains — the opportunities, limitations, and how companies can balance innovation with compliance.

1. What Are Open Hardware Platforms?

Open hardware platforms provide:

- Public access to schematics, layout files, and BOMs

- Open-source bootloaders and BSPs

- Community support and rapid prototyping tools

They offer faster product validation and lower initial investment — ideal for startups and R&D teams. But this transparency also introduces challenges in certification, traceability, and long-term reliability.

2. Regulated Industries: Requirements at a Glance

| Industry | Key Regulations | Critical Hardware Demands |

| Automotive | ISO 26262, ASPICE, UNECE R155/R156 | Functional safety, secure OTA, AEC-Q100 |

| Medical Devices | IEC 60601, ISO 13485, MDR, FDA 21 CFR Part 820 | Traceability, secure boot, long lifecycle support |

| Energy & Utilities | IEC 61850, IEC 62443, NERC-CIP | Cybersecurity, interoperability, robust enclosures |

3. Opportunities for Open Hardware

a. Rapid Prototyping & Feasibility Studies

- Evaluate software features and sensors without committing to final hardware

- Low-cost validation for business cases and UX workflows

b. Pre-Compliance Testing

- Use open hardware to simulate real hardware behavior during EMI, ESD, and software security testing

c. Educational and Workforce Enablement

- Align team knowledge and test environments with mainstream open ecosystems (Linux, Yocto, U-Boot)

4. Challenges and Limitations

a. Lack of Lifecycle Guarantees

- Community boards often have short lifespans and limited vendor support

b. Traceability and Component Certs

- Difficult to validate full chain-of-custody for safety-critical certification

c. Performance and Environmental Limits

- Off-the-shelf open boards may not meet temperature, EMC, or ruggedization specs

d. IP and Cybersecurity Risks

- Openness may expose attack surfaces or conflict with company IP protection policies

5. Best Practices for Adopting Open Hardware in Regulated Projects

- Use open platforms during R&D, but transition to custom or industrial-grade boards for NPI

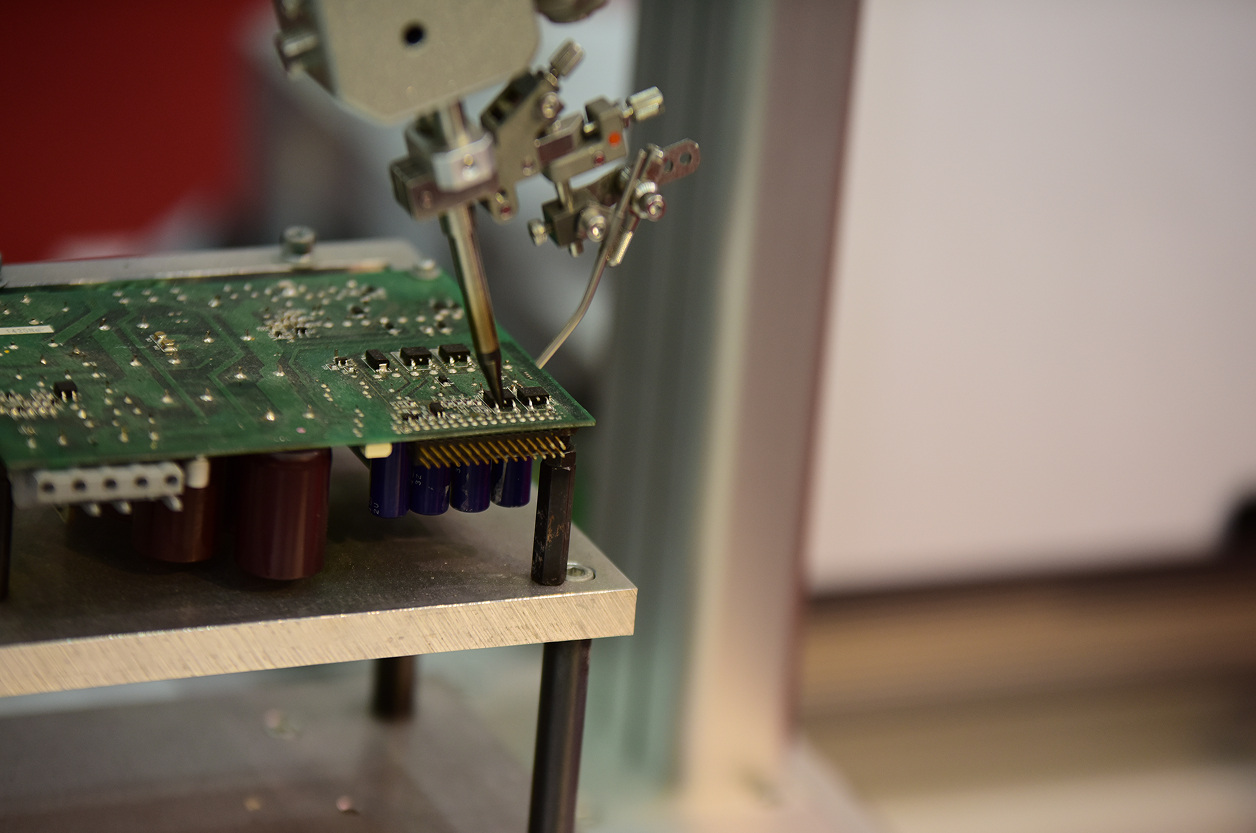

- Collaborate with EMS and design firms to create certifiable custom hardware based on open architecture

- Validate third-party SoMs and SBCs with documented supply chain, lifecycle plan, and test data

- Build firmware abstraction layers to allow reuse across hardware generations

Promwad supports clients in medical, automotive, and energy sectors by adapting open hardware prototypes into robust, compliant designs.

6. Looking Ahead: Can Open Hardware Go Certified?

Emerging trends suggest growing alignment:

- Vendors offering long-life open SoMs with support for IEC and ISO compliance

- Hybrid models combining open schematics with closed, certified production variants

- Government and academic projects pushing for transparent hardware platforms in critical infrastructure

There is no one-size-fits-all, but open hardware can become part of a compliant roadmap — with the right engineering strategy.

7. Case Study: Migrating from Raspberry Pi to Certified Industrial Platform

A European medical device startup developed its first prototype of a portable respiratory monitoring system using a Raspberry Pi 4 for rapid prototyping.

Problem:

- The board lacked IEC 60601 compliance

- No guaranteed lifecycle or traceability of components

- EMI test failures due to unshielded interfaces

Solution by Promwad:

- Designed a custom carrier board around a pre-certified industrial SoM based on NXP i.MX8M Mini

- Implemented secure boot, traceable component sourcing, and medical-grade power management

- Supported client through CE/MDR documentation and EMC test preparation

Outcome:

- Achieved full MDR pre-approval within 9 months

- Extended production planning for 7+ years with reliable SoM support

- Enabled OTA firmware upgrades with secure lifecycle hooks

This case shows how open hardware can help accelerate early-stage development — but successful scaling requires engineering for compliance and long-term support.

Final Thoughts: From Openness to Reliability

Open hardware is a powerful innovation tool — but integrating it into regulated industries demands strategy, customization, and a deep understanding of compliance frameworks.

Promwad helps clients bridge the gap between fast prototyping and compliant mass production — turning open ideas into certified, scalable hardware platforms.

Let’s transform your open hardware prototype into a market-ready solution.

Our Case Studies in Hardware Design