Promwad Introduces MTP Integration for Industrial Automation Solutions

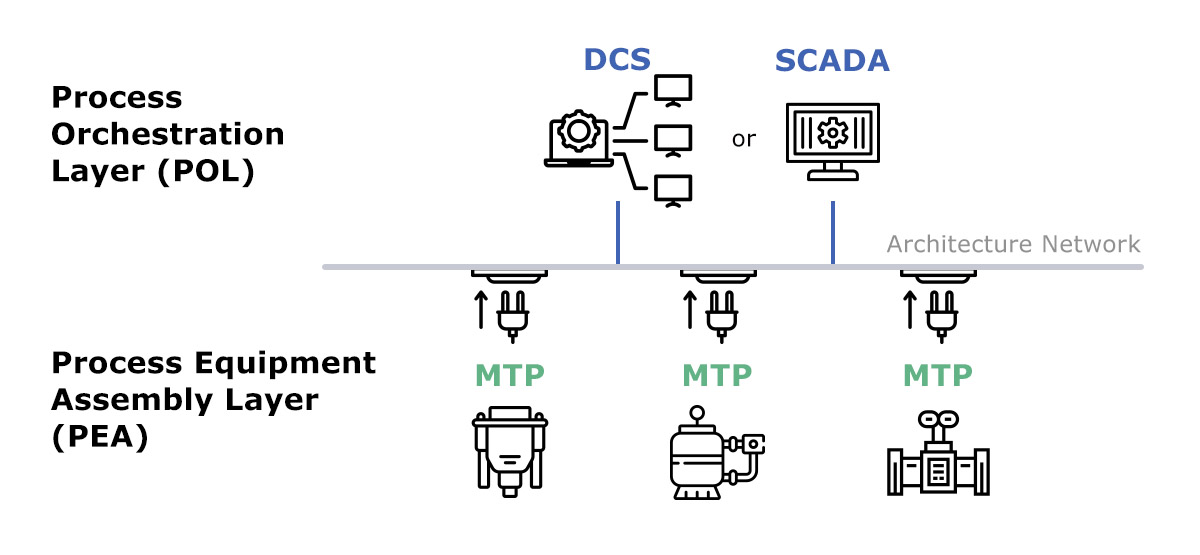

Modular equipment concepts are becoming increasingly common in the automation industry; it simplifies production but makes the entire system more complex, requiring PLCs from different vendors and causing compatibility issues. The response to this challenge is the Module Type Package (МТP) standard that we want to implement in our clients' projects.

Our engineering unit, focused on industrial automation systems, considers the MTP approach the key to modular automation. It creates the framework of interoperability between modules and orchestration systems in industrial automation. Adhering to this standard allows any module to plug into any automation system.

PI was chosen to host MTP technology by key organisations in industrial automation, NAMUR and ZVEI. NAMUR is an international association for automation technology for process industries, and ZVEI is the German association of electrical and electronics manufacturers.

As a member of PI Group, we are ready to help our clients take advantage of the MTP benefits in industrial automation projects. Our engineers will be ready to implement support for this standard as well as dozens of industrial system manufacturers, plant operators and industry associations: ABB, Emerson, Honeywell, Shneider Electric, Siemens, Yokogawa, and many others.

MTP system architecture

The MTP file is at the core of the standard, which acts as an interface to the process equipment assembly (PEA). This file includes all the basic information needed to configure communications, labels, services, and HMIs, allowing the PEA to be monitored and managed. Using the internationally standardised XML data format for automation AML (automation markup language), the MTP files define each component of the equipment.

“With MTP, we can offer our clients a new high level of communication in industrial automation projects. This framework allows us to integrate disparate systems, optimise workflows and achieve high standards of efficiency and productivity,”

said Roman Shuliankou, Head of Industrial Automation Unit at Promwad Electronics Design House.

Here are some examples of industrial automation projects where MTP can be used:

Production line monitoring and control. MTP helps to connect and communicate between the various sensors, actuators and control systems on a production line. It allows real-time monitoring of equipment status, production rates and quality control parameters. Operators can remotely adjust settings, diagnose problems and optimise processes to maximise efficiency and minimise downtime.

Inventory management and logistics. In a warehouse or distribution centre, MTP will facilitate communication between inventory management systems, automated storage and retrieval systems and automated guided vehicles or conveyors. Users monitor stock levels accurately, automate replenishment processes and route goods efficiently.

Energy management. Through integrating smart meters, different devices and building management systems, MTP enables real-time monitoring and control of energy consumption in different production processes and equipment.

Predictive maintenance. MTP can be integrated with predictive maintenance systems to monitor the condition of machinery and equipment. By collecting and analysing data from sensors measuring parameters such as temperature, vibration and lubrication status, MTP enables early detection of potential problems and proactive maintenance activities.

Quality assurance and traceability. In food or pharmaceutical manufacturing, MTP assists in tracking and recording critical process parameters, production metrics and batch information throughout the production process. Manufacturers get visibility and traceability, promoting regulatory compliance and ensuring product quality and safety.

PI is constantly improving the technology, and working groups are currently updating specifications on modelling, HMI integration, and process control.

Ready to discuss the possibility of integrating MTP into your projects? Let's delve into the details!