SRCI with PROFINET: Adopting Cross-Vendor Standard Interface for Robots & PLCs

If you want to control industrial robots with PLCs from different manufacturers, then SRCI can do the job. This Standard Robot Command Interface within the PROFINET standard provides fast and efficient operation. Now, our clients can implement SRCI into their robotics systems with our engineering support.

SRCI standardises the interface for robotic operations, simplifying the work for PLC specialists in robotics. It acts as a single software compatible with different PLC brands and maintains a universal library for various robots. Let's explore what SRCI is, its application areas, and its benefits.

Table of contents

1. What is SRCI

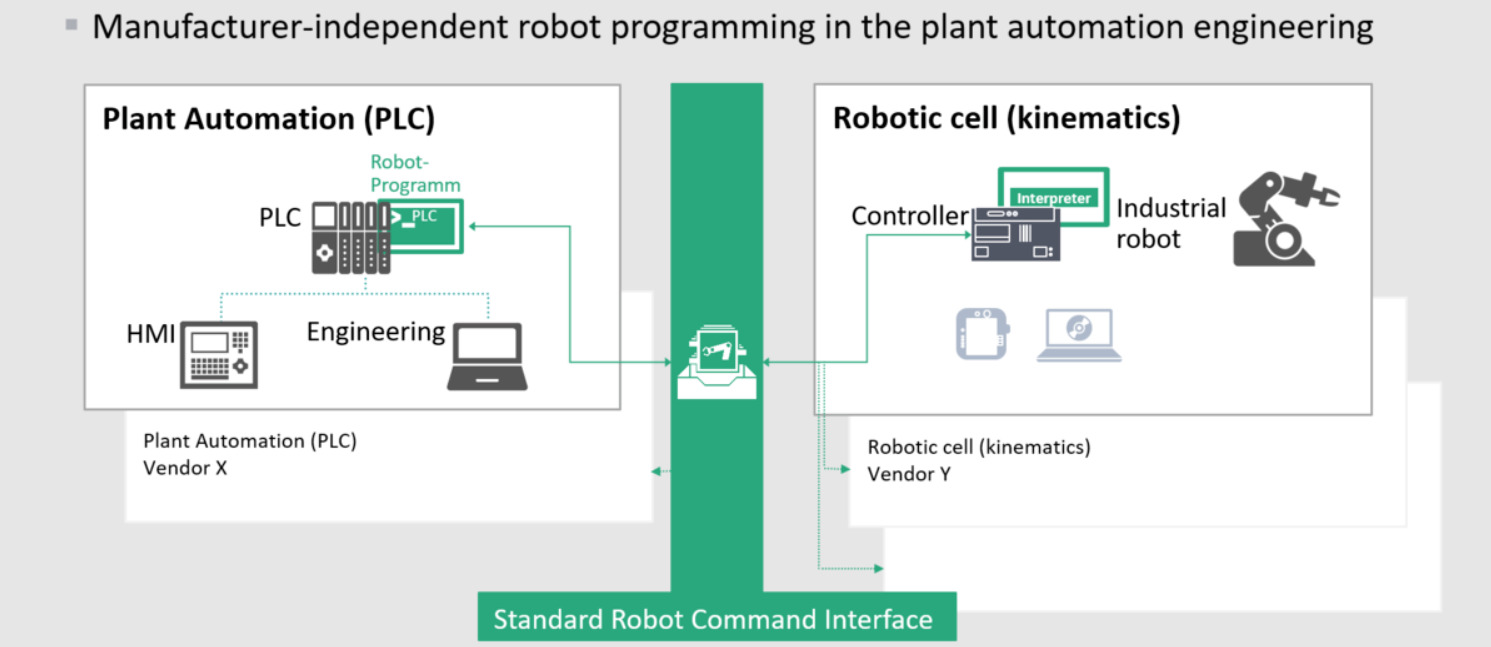

The SRCI interface standardises communication between robots and programmable logic controllers (PLCs) with the goal to make robotics for industrial applications easier to operate. It levels out the differences between robot systems from different manufacturers, making them compatible.

SRCI is part of PROFINET applications designed for greater openness, compatibility, and interchangeability of devices from different manufacturers and industries. SRCI via PROFINET enables fast robot programming in a PLC engineering environment by allowing users to design a complete machine program, including robots, and then integrate the program and robot operation into the PLC.

This interface is gaining widespread adoption among major market players. Siemens, for example, offers the SIMATIC Robot Integrator program, which allows for the quick and easy integration of robots from various manufacturers into the machine structure via the TIA Portal.

2. SRCI benefits for business

In industrial automation, SRCI offers many benefits designed to improve the efficiency of robotic operations. Here are the primary advantages:

- Standardisation across platforms

SRCI supports uniformity of robot control commands across platforms and manufacturers that makes easier the integration of robots from different manufacturers into a single framework.

Manufacturer-independent robot programming in plant automation engineering. Source: profibus.com

- Increased flexibility and interoperability

The Standard Robot Command Interface facilitates the reprogramming or integration of robots into new systems, increasing their adaptability to changes in production demands or system upgrades.

- Reduced development and integration time

Using a standard command interface, SRCI reduces the time and resources required to develop and integrate robotic systems, reducing project costs and accelerating the deployment of new automation solutions.

- Simplified training and maintenance

The standardisation SRCI means that engineers and technicians need to know only one interface rather than multiple systems for different robots.

- Enhanced compatibility and future-proofing

SRCI ensures that robotic systems are compatible with forthcoming technologies and standards. This compatibility enables businesses to remain competitive without frequent overhauls or extensive modifications to their systems.

- Improved efficiency

SRCI enhances the optimisation of robotic operations to help reduce task duration and minimise errors.

3. SRCI application areas

The SRCI offers a wide range of applications in industrial automation, which can be useful across different fields.

Here are some of the main application areas for SRCI:

- manufacturing automation,

- automotive industry,

- electronics assembly,

- pharmaceuticals and healthcare,

- food and beverage industry,

- warehouse and logistics,

- agriculture,

- research and development.

4. For engineers: how SRCI works

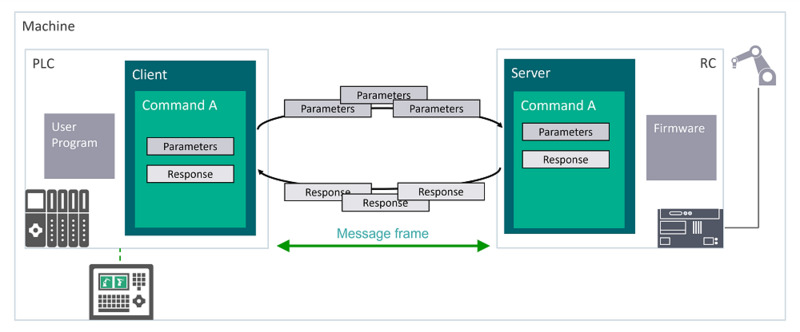

The interface between a PLC and a robot controller (RC) operates on a client-server model that uses remote procedure call mechanisms. In this setup, the PLC, functioning as the client, sends command messages and parameters to the RC, which acts as the server. The RC, in response, sends back messages specific to each command. Arguments and responses can vary depending on the command.

Standard Robot Command Interface's operating chart. Source: profinet.com

The client's role in SRCI-based systems is to issue commands to the server, receive responses, update these commands, and forward the revised list of arguments to the server. In turn, the server informs the client about the command execution, indicating whether it is busy, active, or completed.

PROFINET facilitates communication between the PLC and the RC, where the RC functions as an IO device, and the PLC serves as an IO controller.

***

SRCI is a step forward in industrial automation that benefits PLC manufacturers, robot suppliers and end-users at the same time. By standardising robot control commands, SRCI simplifies the integration of different robotic systems and makes them adaptable to changing business and technology needs.

As a member of the PI group, Promwad is ready to leverage all the capabilities of SRCI, ensuring that all the advantages of this interface will integrate into your project.

Do you want to implement the Standard Robot Command Interface into your industrial automation system? Contact us, we will offer the best engineering solution for your specific application!