Promwad Is Ready to Support IEC/IEEE 60802 TSN Joint Profile for Industrial Automation (TSN-IA)

The Promwad engineering team is ready to develop software and design hardware for device manufacturers supporting the new IEC/IEEE 60802 Time Sensitive Networking for industrial automation. The work on TSN-IA is ongoing; the next working group session is scheduled for January 2023. And in the meantime, we are ready to share with you the features and benefits of this new profile.

IEC/IEEE 60802 is a new standard that defines time-sensitive networking profiles for industrial automation. The TSN-IA profiles will describe configurations, protocols, features, options, defaults, and procedures of end stations, bridges, and LANs for industrial automation networks.

What TSN-IA is used for

Data transmission over Ethernet can be delayed or fragmented. The receiving device assembles a single file from disparate parts of an array of data that may not arrive in the correct order. It is not a critical problem in some industries. Still, industrial automation is an area where even minor delays in data transmission (a few hundredths of a second) can cause systems to fail.

Time-Sensitive Networking (TSN), a list of standards for various industries responsible for real-time data transmission, solves this problem. And the TSN-IA profile is being developed specifically for industrial automation (IA).

IEC/IEEE 60802 TSN Joint Profile is a common standard for layer 2 of the OSI model, describing communication with PLCs and other equipment.

Several industry-leading companies are developing the standard: Schneider Electric, Siemens, B&R, Beckhoff, Ericsson, Rockwell Automation, Nokia, ABB, and Bosch Rexroth.

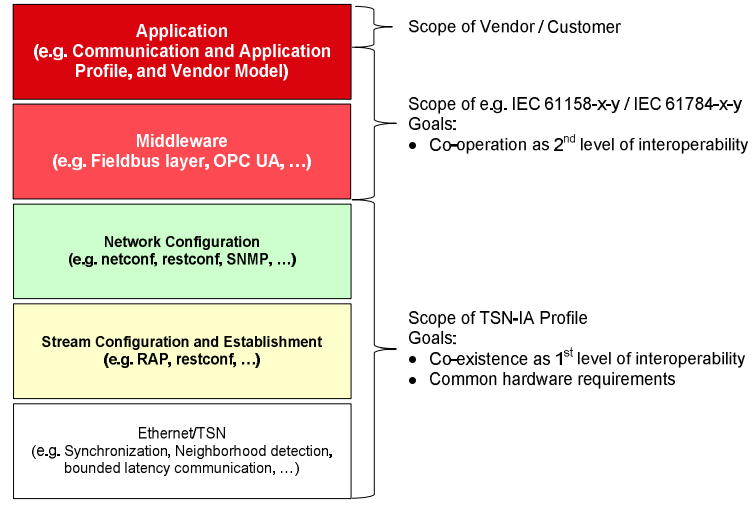

The objectives of each phase of the IEC/IEEE 60802 TSN Joint Profile work are shown below:

Outline of the work on the new IEC/IEEE 60802 TSN Joint Profile:

where the changes will take place and what the goals of each stage are. Source: ieee802.org.

Advantages of the TSN-IA profile

The new TSN profile for industrial automation will solve two crucial tasks for industrial networks: to transmit data in real-time without errors and to ensure the security and reliability of the transmission process. Here are the features of TSN-IA that will make it possible:

- Traffic shaping: several types of traffic with different bandwidths and latency requirements can pass through the same network.

- Reservation of traffic lanes for certain types of communication.

- Ensure time synchronisation when transmitting data from different devices and applications.

- Low-priority frames are interrupted and resumed when the traffic ends.

The main advantage of using the TSN-IA profile in industrial automation is the unification of the data link layer or OSI model layer 2, which enables data to be transmitted across the physical layer between nodes in a network segment.

Why the TSN-IA profile is not a substitution for industrial networks

With all the benefits of the new profile, TSN will not replace industrial networks that operate on technologies from the PI Group, ODVA, and CC-Link.

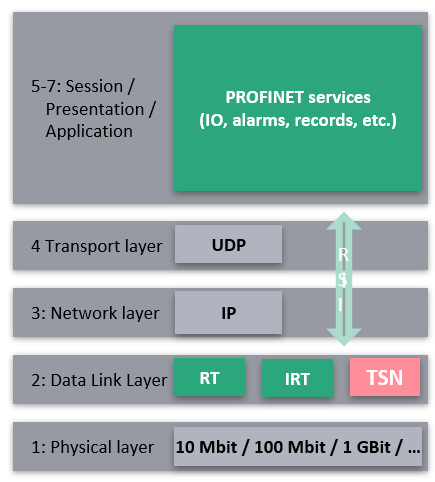

TSN operates at layer 2 of the OSI model and is the underlying technology for communication standards such as PROFINET TSN, EtherNet/IP TSN, Sercos III TSN or CC-Link IE TSN.

The TSN-IA profile ensures that data is transferred from one point to another. All further data processing takes place at higher levels.

As with EtherCAT, TSN profiles are used for general-purpose networks with no specific hardware limitations and features.

TSN protocol at layer 2 of the OSI model. Source: us.profinet.com

PI Group technologies

PROFINET standards enable important processes in factory automation: cyclic and acyclic data transmission, alarms and diagnostics, and parameterisation. TSN-IA will not be able to implement these functions.

EtherNet/IP from ODVA, standards development organisation

TSN-IA performs the function of communication between switch equipment and field equipment like PLCs and higher-level systems. These are just some of the functions that EtherNet/IP will be able to realise when interfacing with TSN-IA:

- support for isochronous control loops and cyclic control loops with bounded latency;

- ensuring a sequence of events;

- adjustment machine to machine/controller to controller communication (M2M/C2C);

- safety.

CC-Link IE TSN protocol

CC-Link IE TSN is the first network to utilise gigabit Ethernet bandwidth and TSN technology. It operates at layers 3–7 of the OSI model, using TSN from layer 2 as the base. This enables openness, high data rates, increased functionality and easier use of IP devices.

Therefore, TSN-IA will not be a substitute but an addition to the industrial networks we have analysed above, as it will extend the functions of OSI layer 2: performance, security, and real-time data transmission.

***

Promwad is monitoring the development of IEC/IEEE 60802 for time-sensitive networking, which will run on industrial protocols PROFINET, Modbus, EtherNet/Ip, Sercos III, VARAN, MECHATROlink III. Feel free to contact us to discuss the development of your software or hardware solution with TSN-IA support.

Our projects

Would you like to ensure TSN-IA support in your software and hardware solutions?

Drop us a line about your project! We will contact you today or the next business day. All submitted information will be kept confidential.