Why Hardware Startups Fail — and How Engineering Strategy Can Save Them

Introduction: Hardware Is Hard — But Failure Is Not Inevitable

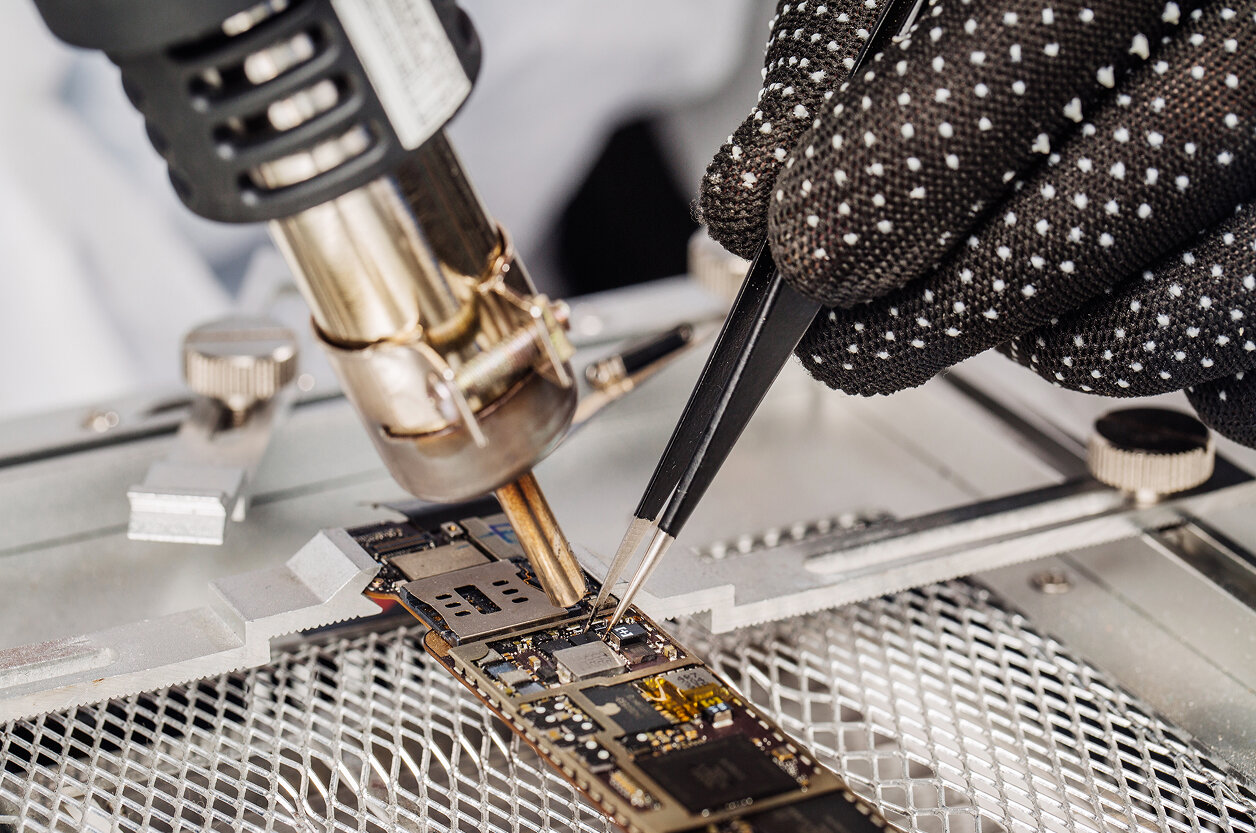

Software startups can iterate fast. Hardware startups? Not so much. Long development cycles, high upfront costs, and manufacturing complexity make building hardware especially risky — especially for first-time founders.

Yet, many failures come not from bad ideas, but from weak execution in engineering and product development. In this article, we examine why hardware startups fail and how a robust engineering strategy can drastically improve the odds of success.

1. Underestimating Time and Cost of Hardware Development

Unlike software MVPs, hardware requires:

- Custom PCB design and prototyping

- Regulatory testing and certification

- Tooling for mechanical enclosures

- Manufacturing and supply chain coordination

Common mistakes:

- Assuming hardware can be done “lean” in 2–3 months

- Underbudgeting for iterations or test failures

- Ignoring per-unit cost structure and BOM targets

How to fix:

- Build a realistic timeline with prototyping, pre-certification, and pilot production phases

- Validate BOM costs early with your EMS or DFM consultant

- Use off-the-shelf SoMs or evaluation kits for MVPs

2. No DFM/DFA Strategy from the Start

Many startups focus only on functionality in the early phase — but forget to make the product manufacturable.

Signs of trouble:

- PCBs not optimized for yield or test coverage

- Enclosures difficult to assemble or scale

- Over-customized components not available in volume

What to do:

- Apply Design for Manufacturing (DFM) and Design for Assembly (DFA) principles early

- Involve a contract manufacturer (CM) or EMS partner in the design loop

- Use standard connectors, package sizes, and mounting strategies

3. Ignoring Compliance and Certification

Many hardware startups forget that CE, FCC, or RoHS aren’t just checkboxes — they’re gates to enter global markets.

Common missteps:

- Skipping pre-compliance testing

- Using non-compliant components or wireless modules

- Delaying regulatory planning until too late

Engineering strategy tip:

- Plan certification from day one: identify all needed standards

- Choose pre-certified modules or platforms (e.g. Bluetooth, Wi-Fi)

- Reserve time and budget for lab testing and paperwork

4. Fragmented Firmware and Hardware Co-Development

Hardware and firmware teams working in silos often lead to misaligned interfaces, integration bugs, and delayed validation.

Avoid this by:

- Establishing hardware–software co-design from the beginning

- Sharing interface specifications and version control across teams

- Using emulators and simulators to test firmware before hardware is ready

Promwad frequently bridges firmware and hardware integration for clients launching their first product — reducing bugs and test delays by 30–40%.

5. Failing to Plan for Production and Scaling

Shipping 10 prototypes isn’t the same as building 10,000 units. Many startups get stuck after proof-of-concept due to a lack of:

- Test automation

- Supply chain coordination

- Yield monitoring and post-sale support

Build with scale in mind:

- Add test points and debug headers to every board

- Develop scalable test jigs and flashing stations

- Use an ERP or tracking system early for logistics

Summary Table: Top Startup Failures and How Strategy Prevents Them

| Pitfall | Resulting Risk | Strategy to Prevent It |

| Underestimating time/cost | Missed launch, budget overrun | Phase planning, validated BOM |

| No DFM/DFA | Unbuildable design, high unit cost | Early EMS engagement, standard components |

| Skipping compliance | Market access blocked, legal risks | Pre-cert labs, certified wireless modules |

| Siloed HW/SW teams | Firmware bugs, integration delays | Co-design, shared specs, test simulators |

| No production scale plan | Post-MVP failure, QA issues | Test jigs, flashing automation, ERP setup |

6. Lack of Risk Management and Contingency Planning

Hardware development is full of uncertainty — from component shortages to factory defects. Startups often fail to anticipate risk at each stage of development.

Typical oversights:

- Assuming EMS partners will handle every quality issue

- Relying on a single supplier for key components

- No contingency budget for redesigns or compliance rework

Engineering strategy tip:

- Conduct risk mapping (supply chain, design, certification, scaling)

- Build 10–15% contingency into cost and timeline projections

- Develop a component substitution plan and lifecycle monitoring

7. Poor User Feedback Integration

Startups that skip field testing or ignore early user feedback often miss critical flaws that derail the product post-launch.

Examples of missed insight:

- Enclosure heat issues not identified in lab tests

- User confusion due to unvalidated UI/UX

- Field failures due to assumptions about install conditions

Preventative strategies:

- Run structured field trials or beta deployments

- Use telemetry to monitor behavior in real conditions

- Build feedback loops into product update planning

Final Thoughts: Engineering Strategy Is a Startup’s Survival Tool

Most hardware startup failures are avoidable — if product development is grounded in solid engineering practice.

Promwad supports early-stage companies with:

- Architecture planning and design reviews

- Custom hardware/firmware development

- DFM and EMS onboarding

- Certification consulting and lifecycle support

If you're planning to build your first embedded product — or want to fix gaps in your current process — let’s talk. We help startups build smart, scale fast, and avoid painful surprises.

Our Case Studies in Hardware Design