Functional Safety vs. Conventional Hardware Development: What’s the Difference?

Why Functional Safety Requires More Than Just Good Engineering

In a world where electronic systems control everything from car brakes to factory robots, safety isn’t just a feature — it’s a regulatory obligation. While conventional hardware design focuses on performance, cost, and time-to-market, functional safety (FuSa) adds another layer: ensuring the system behaves safely even under fault conditions.

In this article, we compare traditional hardware development with functional safety–driven design, highlighting where processes diverge — and why it matters for automotive, industrial, medical, and aerospace sectors.

What Is Functional Safety?

Functional safety refers to a system’s ability to detect, manage, and mitigate hardware or software faults that could lead to hazardous events. It’s defined by standards like:

- ISO 26262 – Automotive functional safety

- IEC 61508 – General safety of electronic systems

- ISO 13849 / IEC 62061 – Industrial machinery

- IEC 60601-1 – Medical electrical equipment

These standards define processes, documentation, and verification requirements for hardware and software systems that could impact human life or critical infrastructure.

Key Differences in Workflow

| Development Phase | Conventional Hardware | Functional Safety Hardware |

| Requirements Definition | Focused on features and performance | Includes hazard analysis and risk classification |

| Architecture Design | Driven by cost, size, performance | Redundant paths, monitoring, diagnostic coverage |

| Component Selection | COTS components based on spec | Safety-rated parts, verified MTBF/FIT values |

| Design Verification | Basic functional tests | Formal verification, fault injection, traceability |

| Documentation | Design files and production specs | Safety case, FMEA, FMEDA, safety manual |

| Certification | Optional (e.g., CE) | Mandatory (e.g., ASIL B–D, SIL 1–4, Class C–III) |

Architecture Requirements for Safety

In functional safety, the hardware architecture often includes:

- Redundancy: Dual-channel inputs, mirrored microcontrollers

- Safety monitors: External watchdogs, voltage monitors, temperature sensors

- Diagnostics: Built-in self-tests (BIST), analog/digital plausibility checks

- Degraded operation modes: Safe states when faults occur

In a conventional system, these are rarely needed unless performance or reliability demands them.

Verification and Validation (V&V) Practices

Conventional Projects:

- Functional validation in lab

- Performance measurement and thermal stress tests

- EMC and regulatory testing

Functional Safety Projects:

- Unit-level fault injection (short/open pins, bitflips)

- Fault tree analysis (FTA)

- Failure Mode and Effects Analysis (FMEA)

- Fault-Metric evaluation: FIT rates, SPFM, LFM

- Traceability between requirements → design → test cases

Real-World Impact of Safety Engineering

| Industry | Application Example | Safety Requirement |

| Automotive | ADAS camera module | ASIL B–D compliance |

| Industrial | Servo Drive | SIL 2 or SIL 3 |

| Medical | Patient-controlled analgesia pump | IEC 60601-1 with hardware alarm paths |

| Aerospace | Flight surface actuator controller | DO-254, DO-178 for mixed criticality |

Without functional safety, a single fault could result in catastrophic damage or loss of life.

Costs and Complexity

| Factor | Conventional Development | Functional Safety Development |

| Time-to-market | Fast | Slower due to process rigor |

| NRE Cost | Lower | Higher (up to 2–5x) |

| Documentation | Minimal | Extensive |

| Testing Infrastructure | Basic | Custom test benches + tooling |

Companies that don’t plan for safety early often find themselves needing a complete redesign.

Should You Design for Functional Safety?

Ask these questions:

- Can system failure harm a person?

- Will the device operate in mission-critical or hazardous environments?

- Are you targeting automotive, medical, rail, or aerospace markets?

- Do clients or regulators require compliance with ISO, IEC, or DO standards?

If the answer is yes, FuSa isn’t optional — it’s foundational.

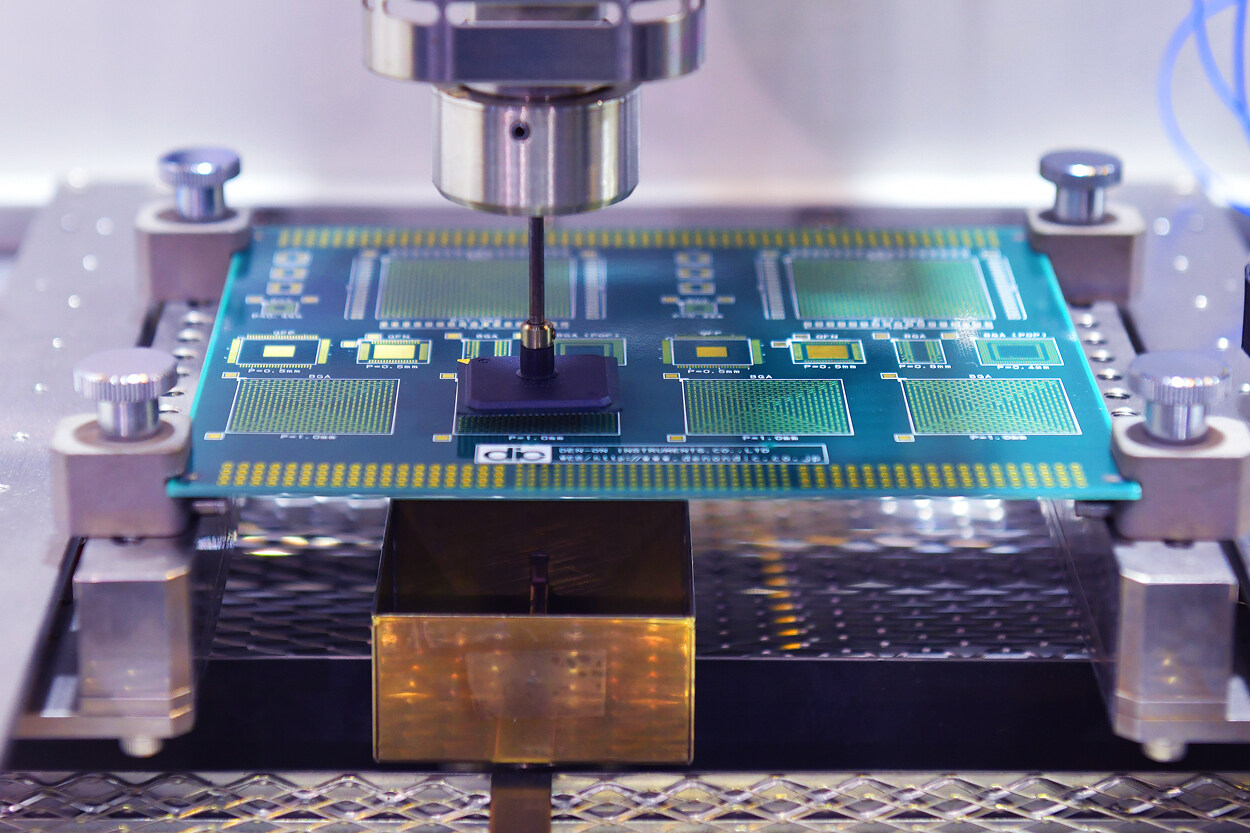

How Promwad Supports Functional Safety Projects

We help clients:

- Design hardware architectures with safety in mind

- Select certified components and fault-detecting ICs

- Develop compliant documentation (FMEA, safety manuals, traceability)

- Implement and verify diagnostics and redundancy

- Prepare for third-party audits and certifications

Our teams have experience in both ISO 26262 and IEC 61508 projects — across automotive ECUs, industrial PLCs, and safety sensors.

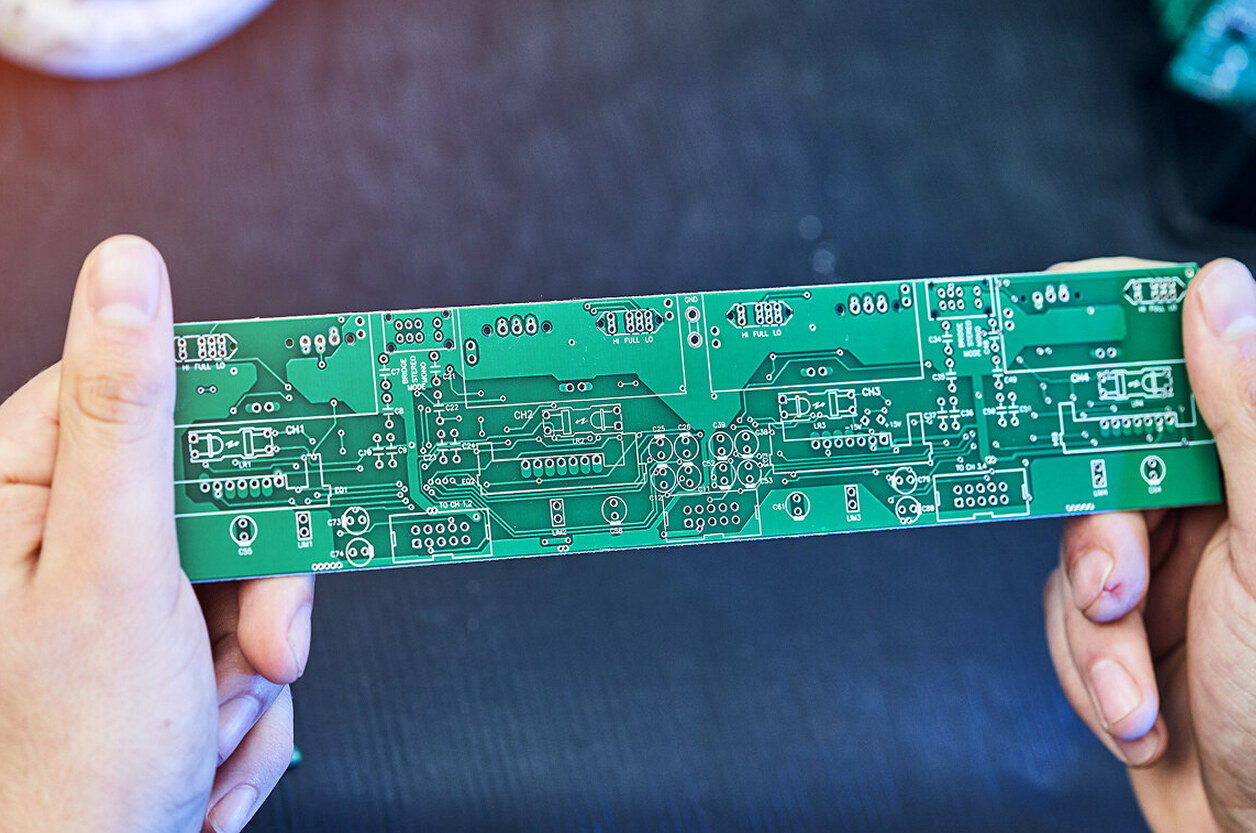

Final Thoughts

Functional safety isn’t just an engineering overhead. It’s a mindset and methodology that creates robust, reliable, and certifiable systems — especially as electronics take over safety-critical roles.

At Promwad, we support customers across regulated industries in building functionally safe electronics — from early analysis to final certification.

If your next project involves safety-critical design, we’ll help you get it right — from the first schematic.

Our Case Studies in Hardware Design